A solid-liquid dual-purpose high-temperature and high-pressure carbonization reaction kettle that can indicate the degree of carbonization

A technology of carbonization degree and carbonation reaction, which is applied in the direction of pressure vessels used in chemical processes, chemical/physical processes, and methods of chemically changing substances by using atmospheric pressure. Waste management and other issues, to achieve the effect of low cost, high utilization rate and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

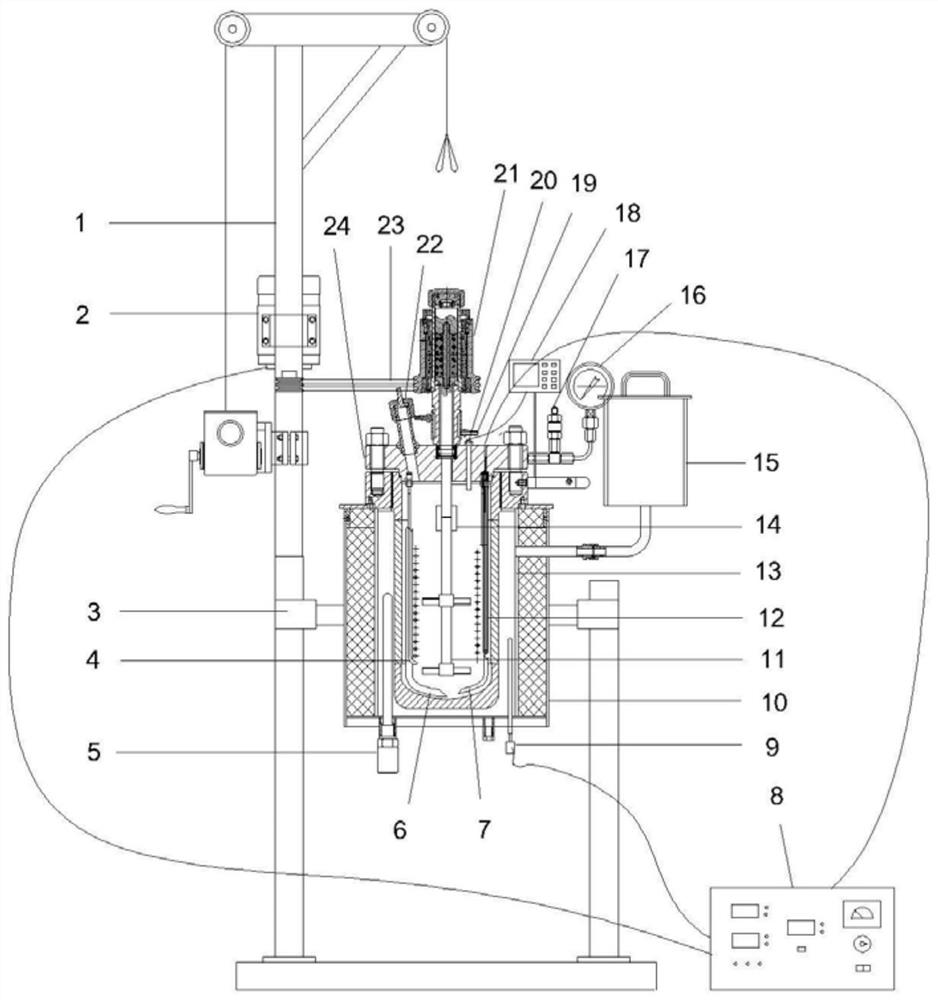

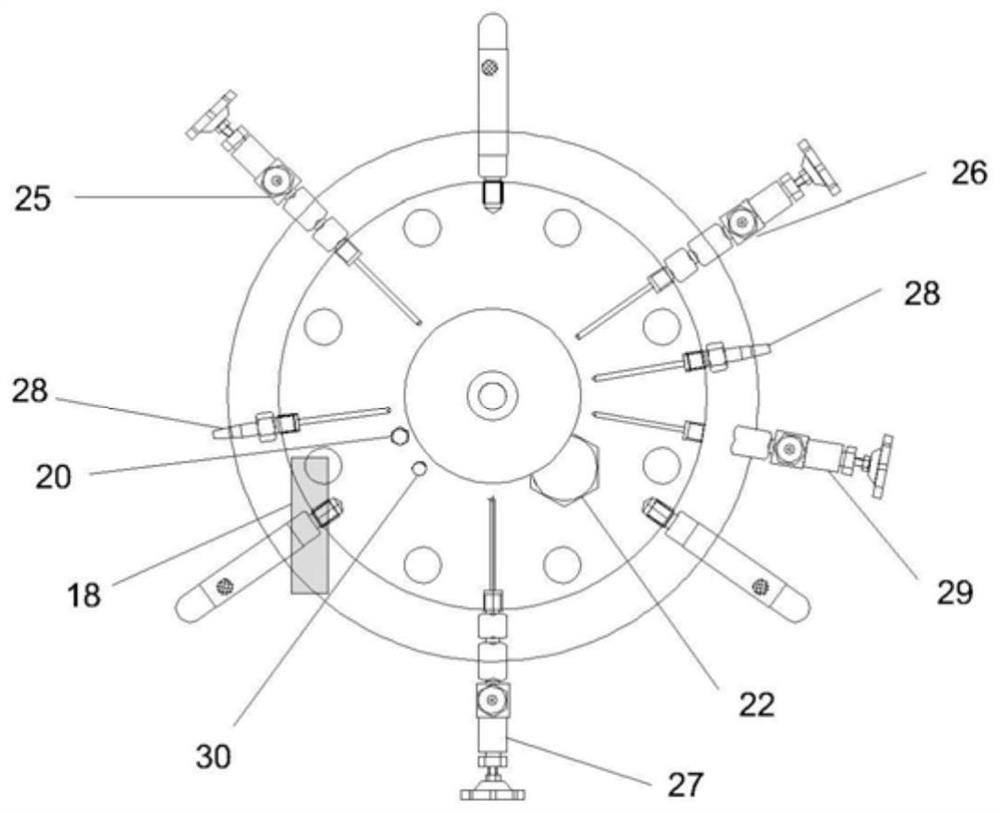

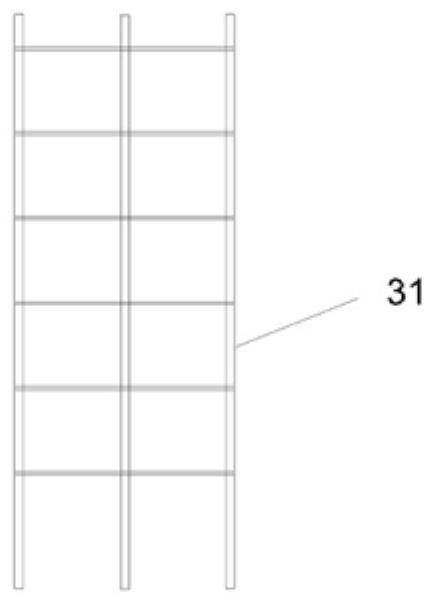

[0055] see Figure 1-Figure 5 As shown, the present embodiment provides a solid-liquid dual-purpose high-temperature and high-pressure carbonization reactor, including a reactor body 10, a kettle cover 24, a motor 2, a stirring member, a test piece support 31, a controller 8, and a reactor body 10 It is connected with the kettle cover 24 by bolts, and the kettle cover 24 is provided with a feed port 22 for feeding into the kettle, an air inlet 25 for connecting with a carbon dioxide inlet pipe, a vacuum port 26 for connecting a vacuum pump, and a vacuum port 26 for discharging The exhaust port 27 for the gas in the kettle, the temperature measuring port 30 for measuring the temperature in the kettle, the upper outlet 29 for releasing the liquid or suspended liquid in the kettle after the reaction is completed, and the cooling water coil for connecting the kettle 4 The cooling water port 28, the pressure gauge port 16 for connecting the pressure gauge, the blast port 17 for con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com