Hydraulic cutting nozzle with residue filer device

A technology of hydraulic slotting and nozzles, which can be used in safety devices, drilling with liquid/gas jets, gas discharge, etc. It can solve problems such as failure, no filter residue function, easy plugging and slotting construction, etc., so as to prevent hole plugging, The effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

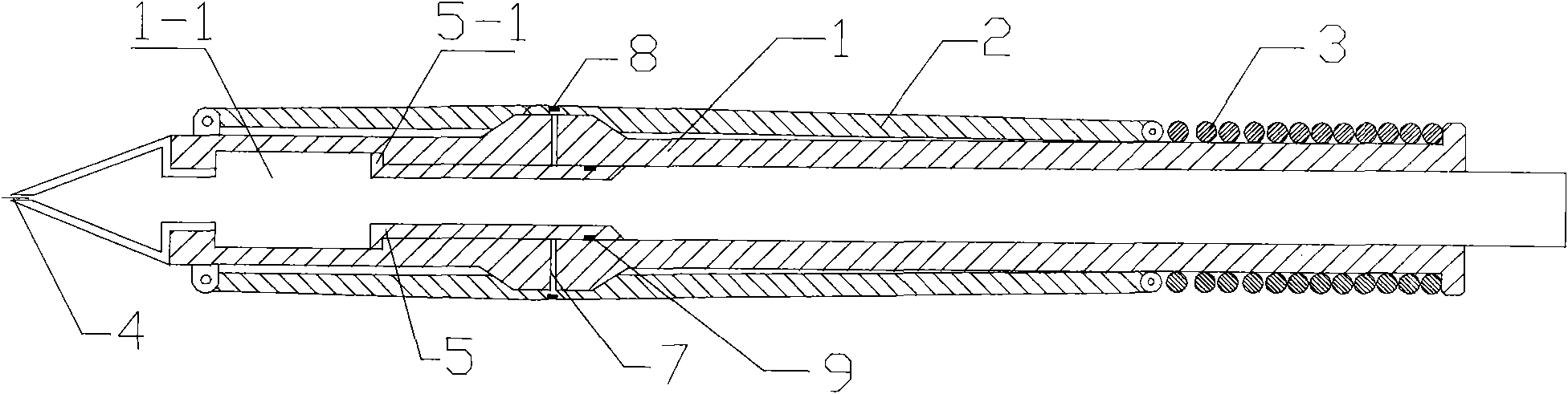

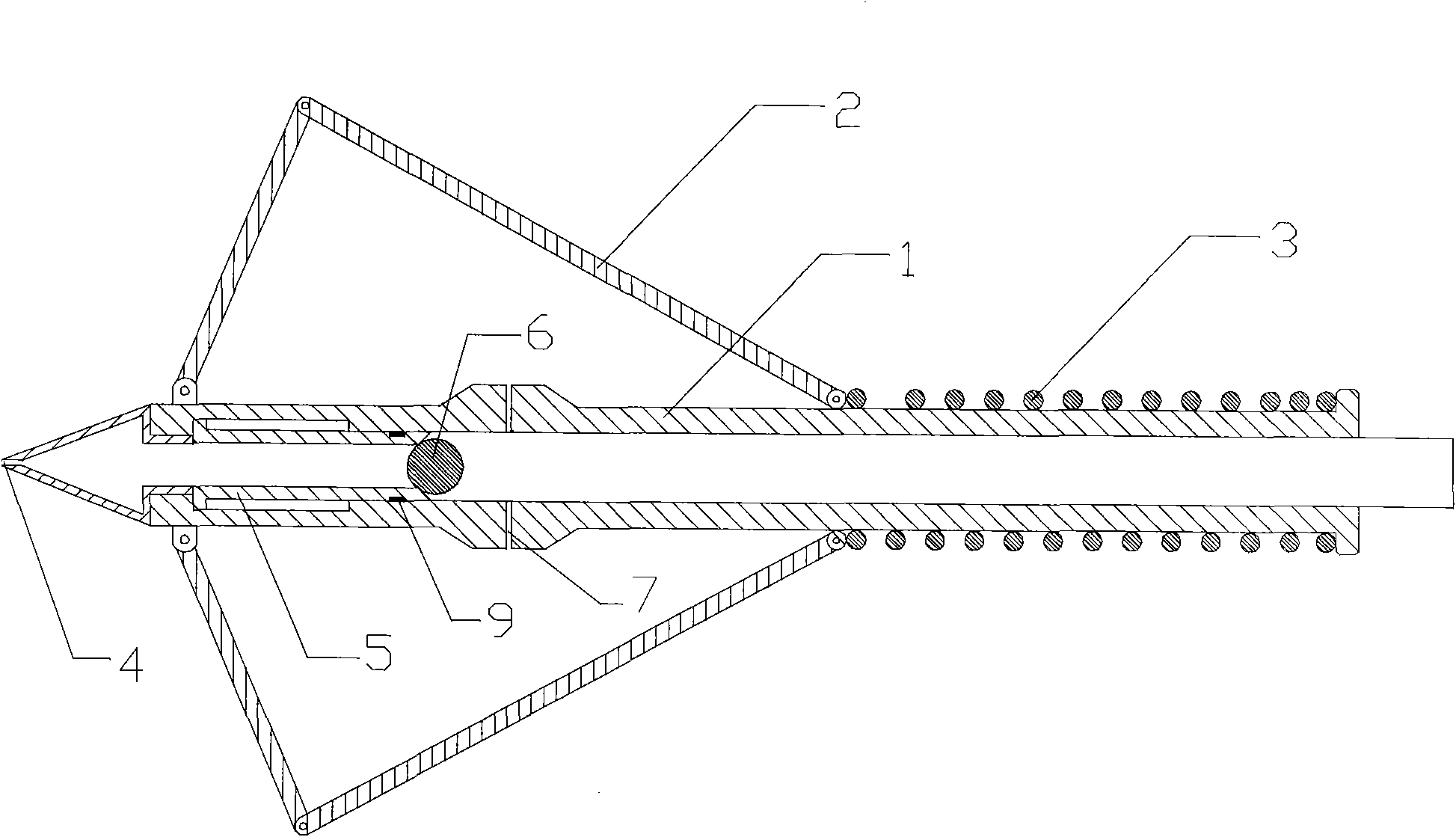

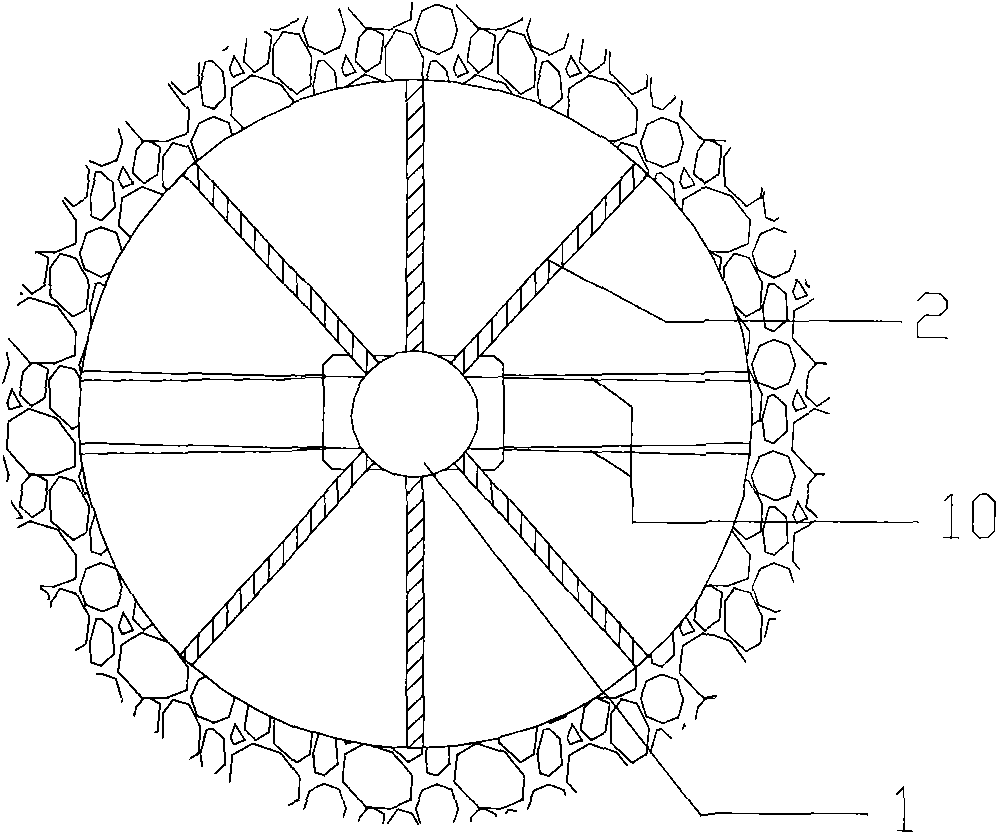

[0013] Such as figure 1 , 2 As shown, a hydraulic slit nozzle with a filter residue device includes: a housing 1, a punching nozzle 4 located at the end of the housing, and a slit nozzle 7 located on the side of the housing; the housing 1 is externally arranged There is a two-stage filter tooth 2 hinged in the middle, the front end of the two-stage filter tooth 2 is hinged at the front end of the housing 1, and the rear end of the two-stage filter tooth 2 is connected to the housing 1 The external return spring 3 is hinged. After the two-stage filter teeth 2 are closed, a disposable plastic hoop 8 is provided at the slit nozzle 7; The front end of the movable core 5 is provided with a positioning shoulder 5-1 that can slide in the front chamber 1-1 of the housing to ensure that the movable core 5 will not move forward in the punching state; the rear end of the movable core 5 It is a spherical surface that can be in contact with the steel ball 6; a sealing ring 9 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com