Leadless soft brazing material

A soldering and soldering technology, applied in welding/cutting media/materials, welding media, welding equipment, etc., can solve the problems of lead-free solder welding performance to be improved, oxidation, plugging and other problems, and achieve good anti-oxidation performance of solder , to avoid plugging holes, the effect of simple manufacturing method

Active Publication Date: 2009-07-08

惠州市成利工业有限公司

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, lead-free solder still needs to be improved in terms of soldering performance. Many lead-free solders used by famous international companies with advanced technology still have shortcomings to varying degrees, such as the SnAgBiIn and SnCu solder alloys used by Mitsubishi, and the SnAgCu solder alloys used by Toshiba. , SnAgCu and SnAgBi solder alloys used by Hitachi, SnZn, SnCu, SnZnBi and SnAgCu used by NEC, etc.

In these solder alloys, after the hot air leveling and tinning of the circuit board, hole plugging and oxidation are prone to occur during secondary soldering.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0029]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

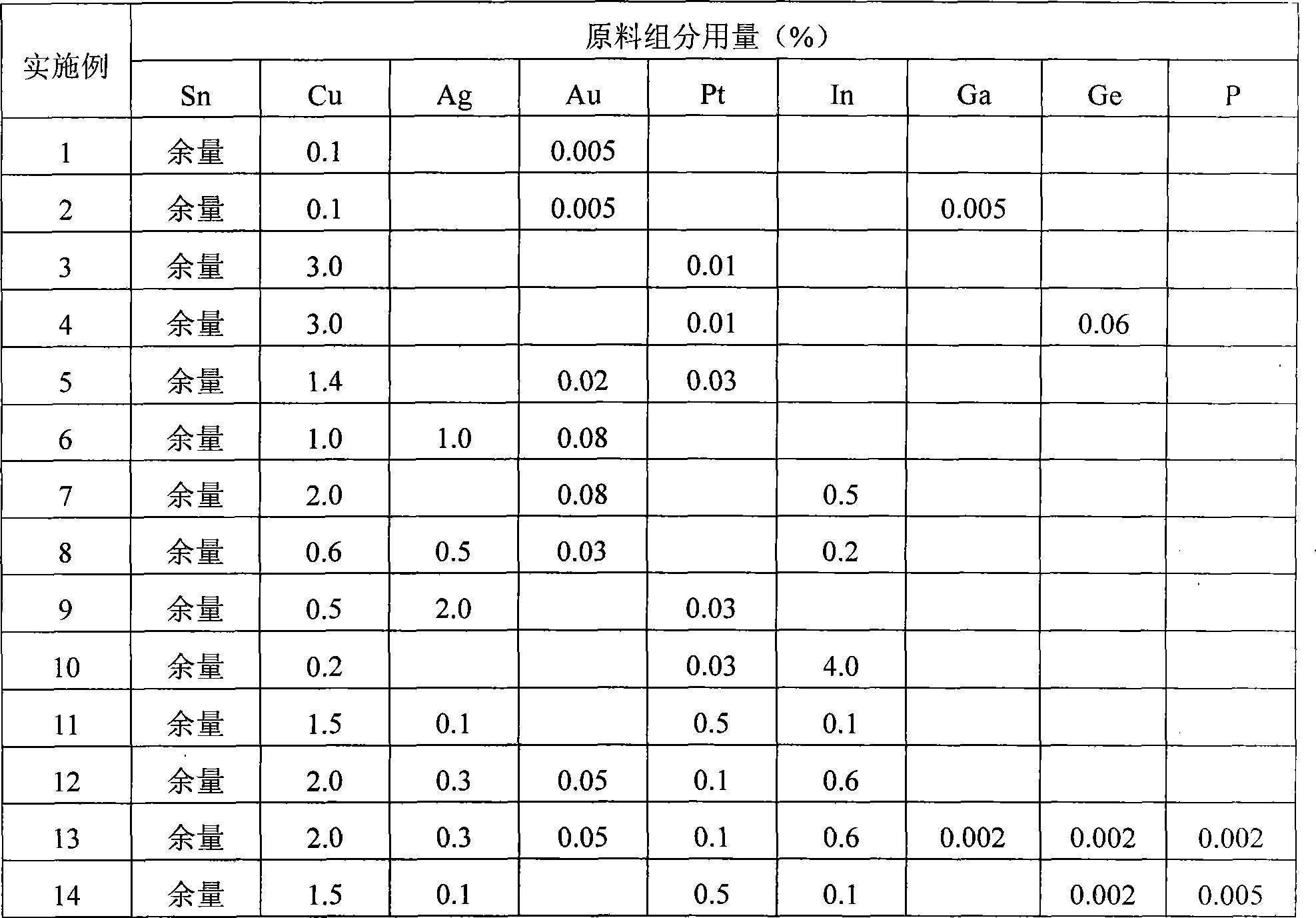

The invention discloses a lead-free soft soldering solder having three basic formations, namely that stannum is used as a base, and according to weight percentage, the solder also comprises 0.1 to 3.0 percent of copper and 0.01 to 0.5 percent of aurum, or also comprises 0.1 to 3 percent of copper and 0.01 to 0.5 percent of platinum, or comprises 0.1 to 3 percent of copper and aurum and platinum which totally occupy 0.01 to 0.5 percent. Argentum and (or) indium, of which the content is not higher than 4 percent according to weight percentage are added to the solder. The lead-free soft soldering solder has favorable antioxygenic property, and effectively avoid the phenomenon of hole blockage during secondary welding; and the production method is simple and is easy to be realized for industrial purposes.

Description

technical field [0001] The invention relates to a lead-free solder. Background technique [0002] At present, the commonly used solder in the electronics industry is tin-lead alloy. Because tin-lead alloy has good wettability and electrical conductivity, good soldering performance and low cost, it is widely used. However, lead and its compounds are very polluting to the environment and will endanger the health of human beings and organisms. From the beginning of this century, countries around the world have increasingly stringent requirements for environmental protection. In the field of electronic soldering, many developed countries, especially the United States and Japan, have already started research on lead-free solder. Many international companies also use lead-free solder in the production of common consumer products, such as motherboards of MinDisc personal computers, notebook computers, mobile phones, TVs, and VCRs. It can be seen that the market potential of lead...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K35/26

Inventor 苏明斌苏传港苏燕旋苏传猛何繁丽

Owner 惠州市成利工业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com