Carbon aerogel/metal organic framework composite material, preparation method and application thereof in gas storage

A metal-organic framework and metal-organic framework technology, applied in the field of polymer materials and gas storage, can solve the problems of no contribution and increase the storage density of ANG

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] In another specific embodiment of the present invention, the preparation method of the above-mentioned carbon airgel / metal organic framework composite material is provided, including:

[0042] 1) Preparing the precursor of the airgel material, adding a chemical crosslinking agent to it to form a sol solution;

[0043] 2) adding the MOF material into the solvent to form a MOF suspension;

[0044] 3) Mix the sol solution prepared in step 1) with the MOF suspension prepared in 2), and prepare the airgel / metal organic framework through the following steps a) or b), and then carbonize it under a protective atmosphere to obtain .

[0045] a) Hydrothermal synthesis to form a hydrogel, after aging and solvent replacement, then perform supercritical drying;

[0046] b) Freeze-drying after freezing for a period of time.

[0047] In yet another specific embodiment of the present invention, in the step 1), the precursor includes resorcinol, formaldehyde, and natural polysaccharide...

Embodiment 1

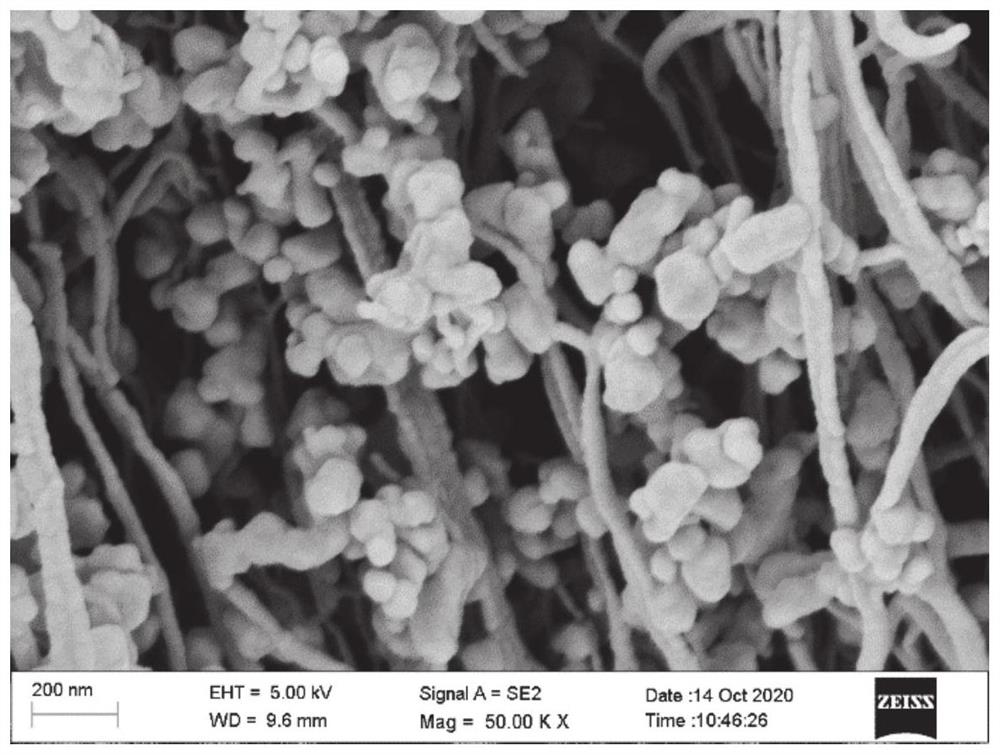

[0065] Example 1 (Cu-MOF / konjac glucomannan-based carbon aerogel)

[0066] Ethylenediamine was dissolved in 100mL of ultrapure water, and the prepared 10%wt (relative to the mass fraction of ethylenediamine) HKUST-1 powder was dispersed in the above solution, and ultrasonically dispersed for 30min. Dissolve 1.5g of konjac glucomannan powder in the above mixed suspension solution, stir for 10min, bathe in water at 90°C for 1h, then transfer to a container, cool to 25°C, transfer to a freezer at minus 40°C for 24h, and then transfer to a freeze dryer Freeze-dry in medium for 1d until all moisture is removed, in N 2 Under protection, the composite material was heated up to 800°C at a rate of 5°C / min in a tube furnace, kept for 2 hours, then cooled and taken out to obtain Cu-MOF / konjac glucomannan-based carbon aerogel.

[0067] After nitrogen adsorption and desorption tests, the composite adsorbent exhibits microporous characteristics with a pore size of 1.2nm-1.8nm, and a pore v...

Embodiment 2

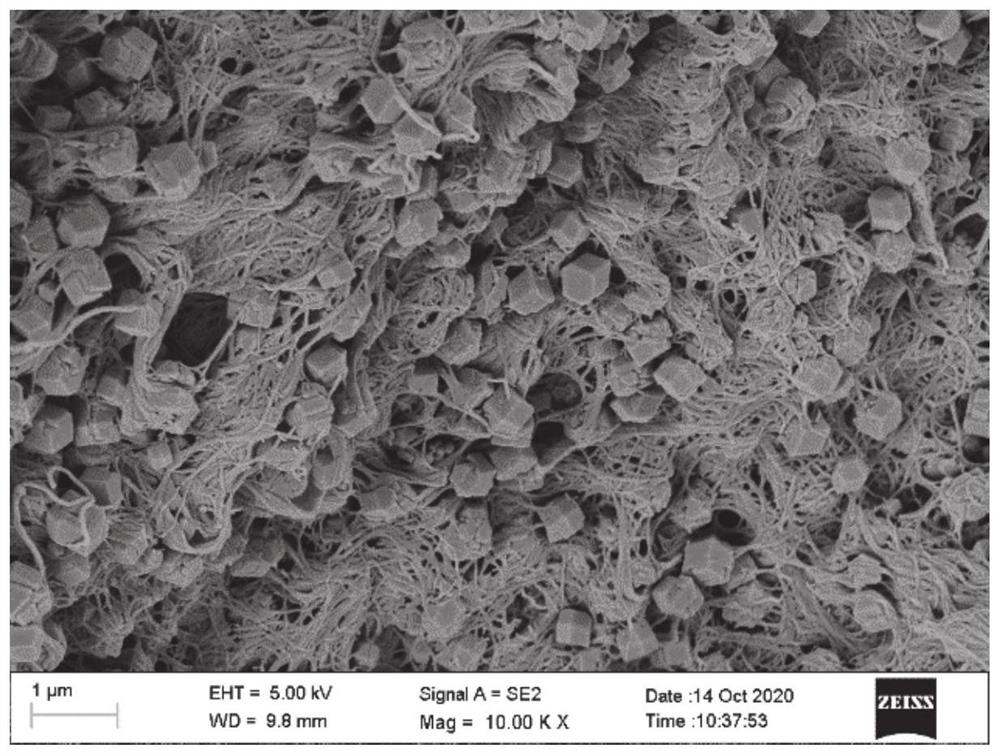

[0069] Embodiment 2 (ZIF-8 / gelatin-based carbon aerogel)

[0070] Dissolve 0.5g of gelatin in 100ml of water, stir for 1 hour, place at 60 degrees until completely dissolved, then add 0.7ml of 37-40wt% formaldehyde solution, stir at 50 degrees for 5 hours, then transfer to the refrigerator for overnight, prepare the next day Good 10% wt (relative to the mass fraction of gelatin) ZIF-8 powder was dispersed in the above solution, and the mixed solution was ultrasonically dispersed for 2 hours, cooled rapidly in liquid nitrogen, and freeze-dried. Then transfer to a freeze dryer and freeze dry for 2 days until all the water is removed. Under the protection of Ar, the composite material is heated to 900 degrees Celsius at a rate of 5 degrees Celsius / min in a tube furnace, and after being kept for 3 hours, it is cooled and taken out to obtain gelatin. Carbon based airgel / ZIF-8 derived carbon.

[0071] After nitrogen adsorption and desorption tests, the composite adsorbent exhibits ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com