Printing nozzle with temperature adjusting function and printing device

A technology for temperature adjustment and printing nozzles, which is applied in the field of printing nozzles and printing devices. It can solve the problems that the shape of the printing material cannot be obtained, the temperature of the printing head is high, and the nozzle is blocked by the printing material, so as to prevent the high solid content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

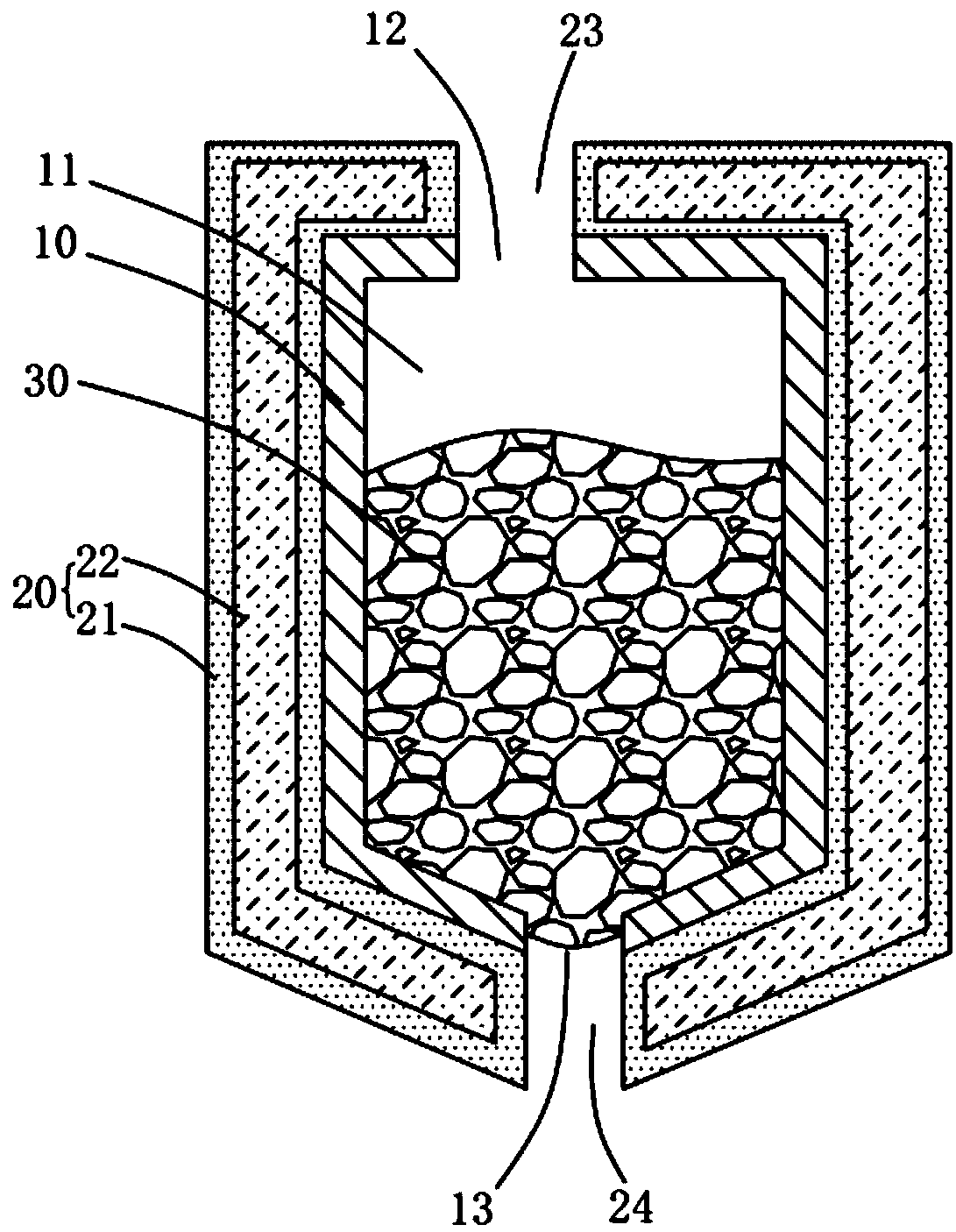

[0023] like figure 1 As shown, the print head with temperature adjustment function according to this embodiment includes a head body 10 and a temperature adjustment layer 20, the head body 10 has a chamber 11, the chamber 11 is used to load printing materials 30, and the temperature adjustment layer 20 is arranged on the head On the main body 10 , the temperature regulating layer 20 is used for regulating the temperature of the shower head main body 10 . In this way, during the printing process, when the temperature of the shower head body 10 rises, the temperature adjustment layer 20 absorbs the heat of the shower head body 10 to reduce the temperature of the shower head body 10, so as to prevent the high temperature shower head body 10 from evaporating the solvent in the printing material 30 , to ensure the stability of the solid content in the printing material 30 and to ensure the stability of the printing process.

[0024] Specifically, as a preferred embodiment, the tem...

Embodiment 2

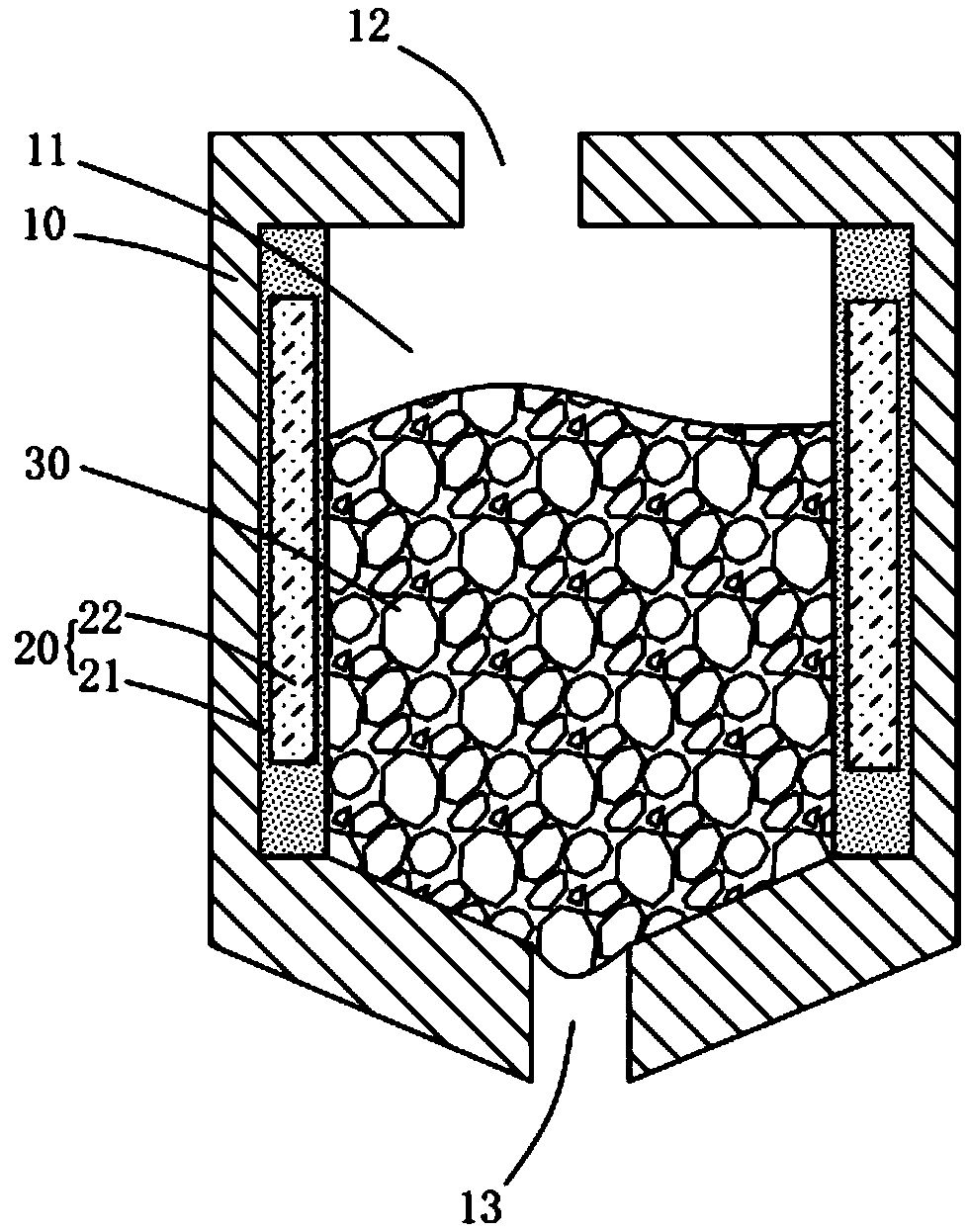

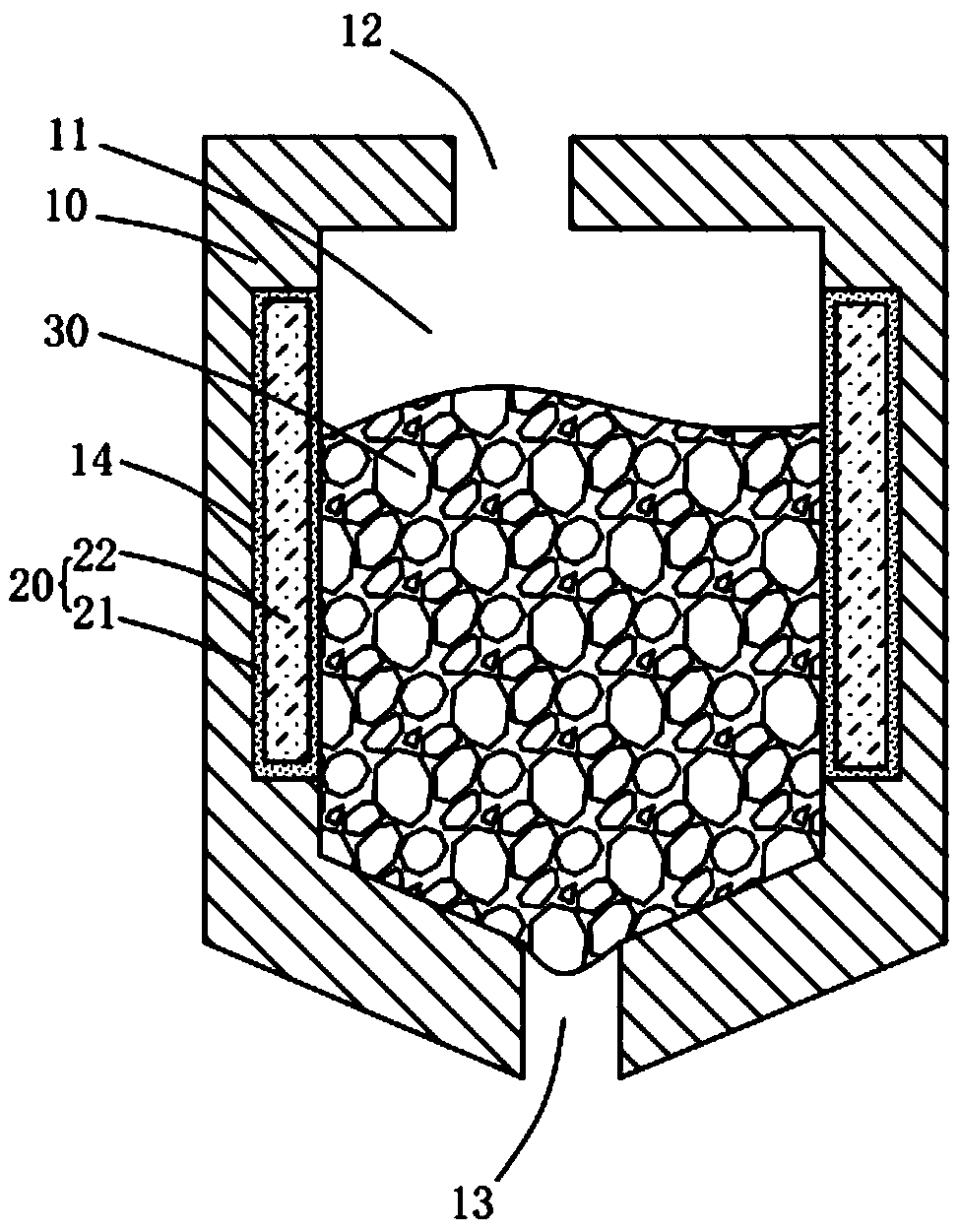

[0031] like Figure 2A As shown, the difference between the printing head in the second embodiment and the printing head in the first embodiment is that the temperature regulating layer 20 in the second embodiment is arranged inside the cavity 11 .

[0032] Specifically, the protective layer 21 of the temperature regulation layer 20 is adhered to the inner wall surface of the accommodating chamber 11 . The shape of the protective layer 21 matches the shape of the inner wall of the accommodating chamber 11 , and the protective layer 21 is fixed on the inner wall by glue. In order to facilitate the installation or removal of the temperature regulating layer 20, the inlet hole 12 of the shower head body 10 should be as large as possible.

[0033] As a preferred embodiment, the protective layer 21 is crimped to form a cylindrical structure, so that when the temperature regulation layer 20 is placed in the accommodating chamber, the protective layer 21 can be closely attached to t...

Embodiment 3

[0037] like image 3 As shown, the printing device according to the third embodiment of the present invention includes the ink supply pipeline 40, the nozzle 50 and the print nozzle with temperature adjustment function in the first or second embodiment, wherein the ink supply pipeline 40 and the nozzle 50 are respectively communicated and accommodated Cavity 11.

[0038] Specifically, the ink supply pipe 40 communicates with the inlet hole 12 , and the nozzle 50 communicates with the outlet hole 13 . Wherein, the number of nozzles 50 may be multiple, and multiple nozzles 50 communicate with the chamber 11 of the same printhead body 10 at the same time, and precise spraying can be realized by controlling the inkjet state of each nozzle 50 .

[0039] In the printing device disclosed in this embodiment, a temperature regulating layer is provided on the nozzle body. During the rapid printing process, when the temperature of the nozzle body rises too fast, the temperature regulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com