System and method for processing micro-channel through femtosecond laser assisted by alternating electric field

A technology of femtosecond laser processing and alternating electric field, applied in the field of femtosecond laser application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

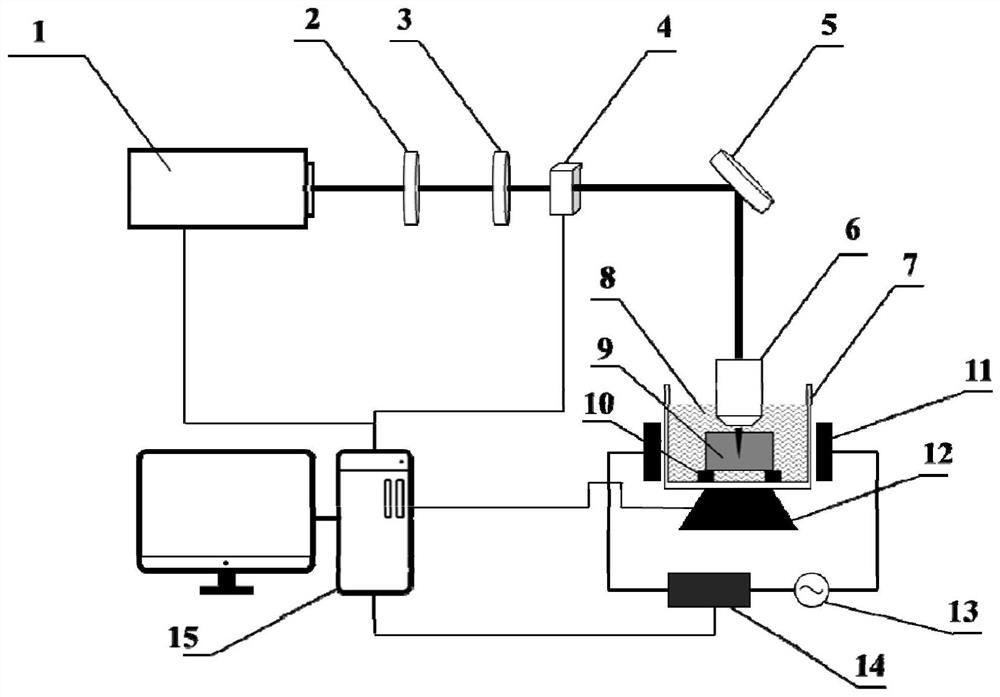

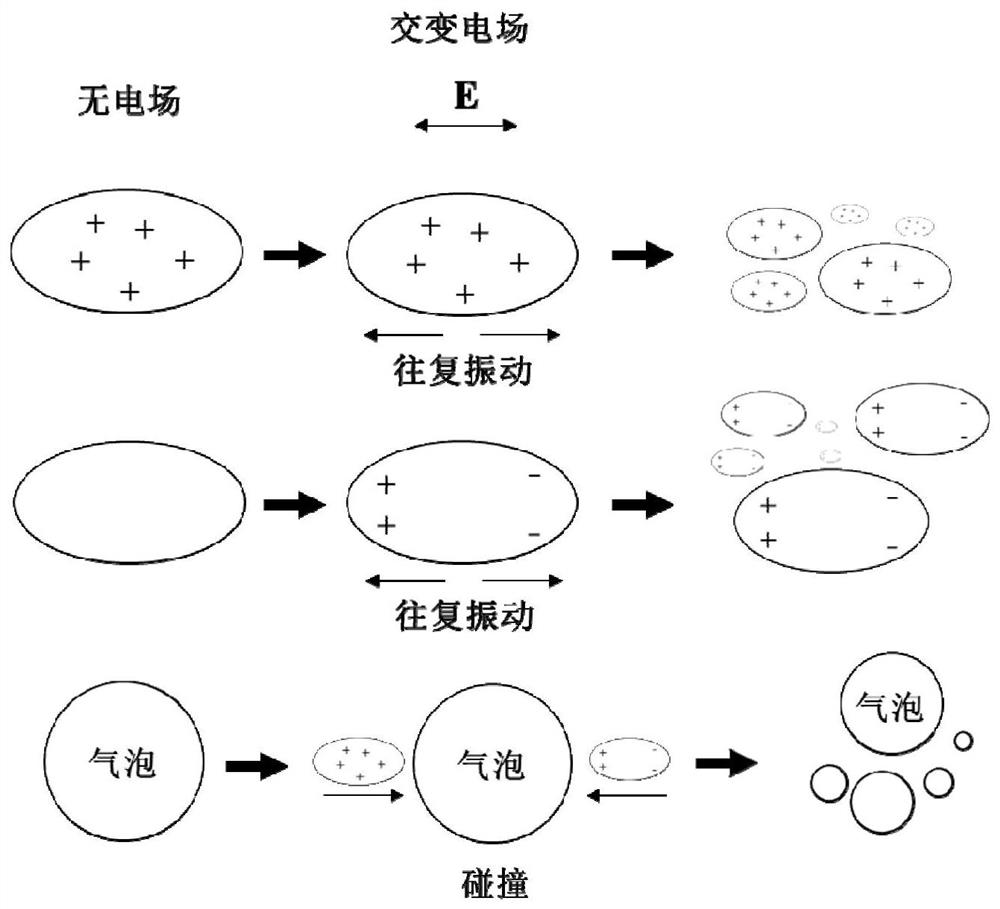

Method used

Image

Examples

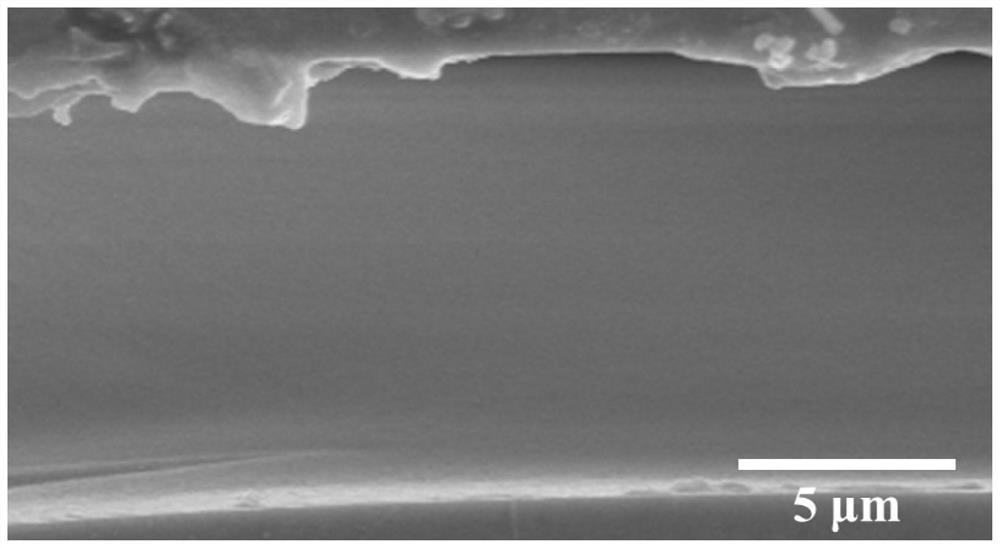

Embodiment 1

[0041] SiO 2 Taking (fused silica) bulk samples as an example, the thickness L of the material sample 9 to be processed is 1100 microns. After the block sample was ultrasonically cleaned with ethanol and deionized water, it was fixed in the clamp 10 in the liquid container 7, leaving a gap of 20 mm below. The liquid in the liquid container 7 is deionized water, and a circuit system of an alternating electric field and a femtosecond laser optical system are built. The laser is focused through a 40X water immersion objective lens 6 (numerical aperture NA=0.90), so that the focal point is located at 20 μm on the lower surface of the sample. Control the optical axis angle of the half-wave plate 2 to set the single pulse energy of the output laser to 2.5 μJ. The control computer software sets the voltage intensity of the alternating electric field to 440V, the alternating frequency to 20KHz, the repetition frequency of the femtosecond laser to 1000Hz, and the moving speed of the ...

Embodiment 2

[0043] Taking the bulk sample of Corning glass (aluminosilicate glass) as an example, the thickness L of the material sample 9 to be processed is 1200 microns. After the block sample was ultrasonically cleaned with ethanol and deionized water, it was fixed in the fixture 10 in the liquid container 7, leaving a 30mm gap below. The liquid in the liquid container 7 is ethanol, and a circuit system of an alternating electric field and a femtosecond laser optical system are built. The laser is focused through a 60X water immersion objective lens 6 (numerical aperture NA=1.0), so that the focal point is located at 15 μm on the lower surface of the sample. Control the optical axis angle of the half-wave plate 2 to set the single pulse energy of the output laser to 1.35 μJ. The control computer software sets the voltage intensity of the alternating electric field to 520V, the alternating frequency to 50KHz, the repetition frequency of the femtosecond laser to 500Hz, and the moving sp...

Embodiment 3

[0045] Taking the borosilicate glass block sample as an example, the thickness L of the material sample 9 to be processed is 500 microns. After the block sample was ultrasonically cleaned with ethanol and deionized water, it was fixed in the fixture 10 in the liquid container 7, leaving a 30mm gap below. The liquid in the liquid container 7 is a potassium chloride salt solution, and a circuit system of an alternating electric field and a femtosecond laser optical system are built. The laser is focused through a 60X water immersion objective lens 6 (numerical aperture NA=1.0), so that the focal point is located at 10 μm on the lower surface of the sample. Control the optical axis angle of the half-wave plate 2 to set the single pulse energy of the output laser to 3.0 μJ. The control computer software sets the voltage intensity of the alternating electric field to 480V, the alternating frequency to 50KHz, the repetition frequency of the femtosecond laser to 1000Hz, and the movi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com