Water-based polymer pigment dispersant and leather cationic pigment paste prepared from same

A water-based polymer and pigment dispersant technology, which is applied in transportation and packaging, dyeing, textiles and papermaking, etc., can solve the problems of easy migration and compound compatibility, low tinting strength and hiding power, poor fineness stability, etc. , to achieve the effect of ensuring storage stability, avoiding water separation and precipitation, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

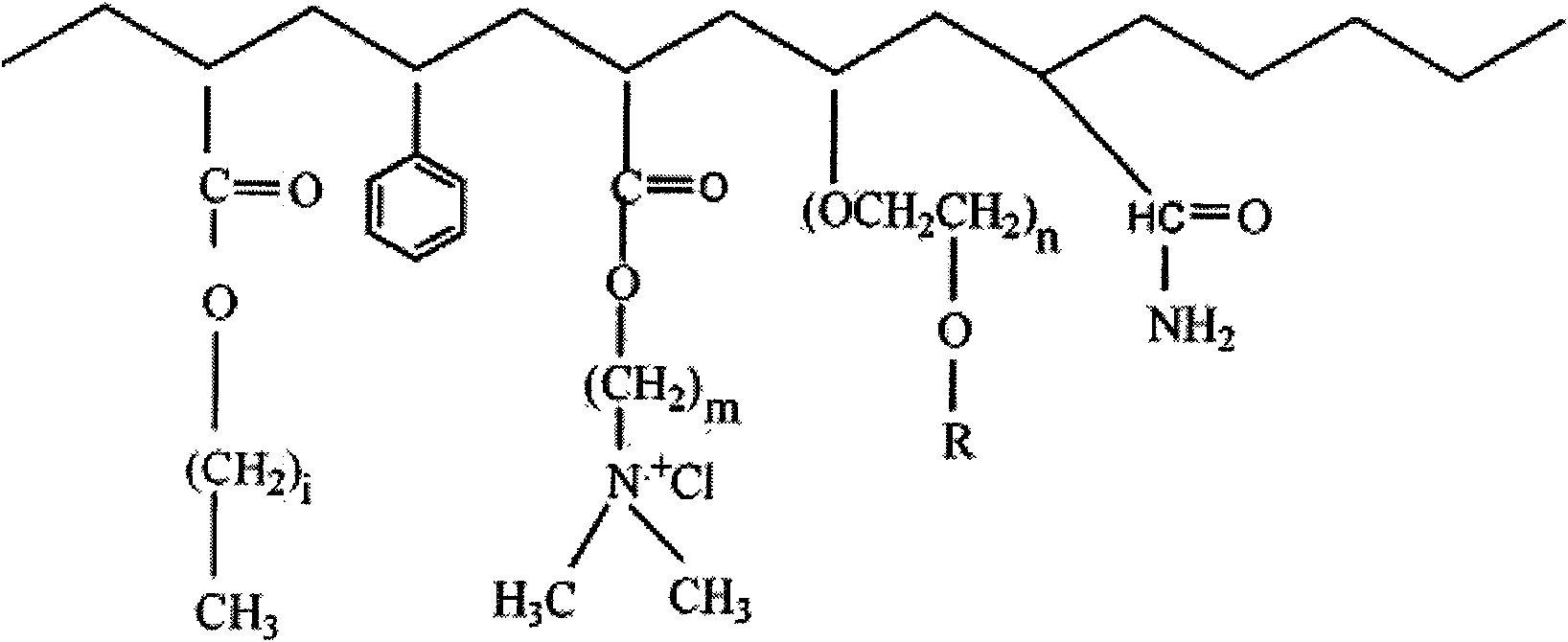

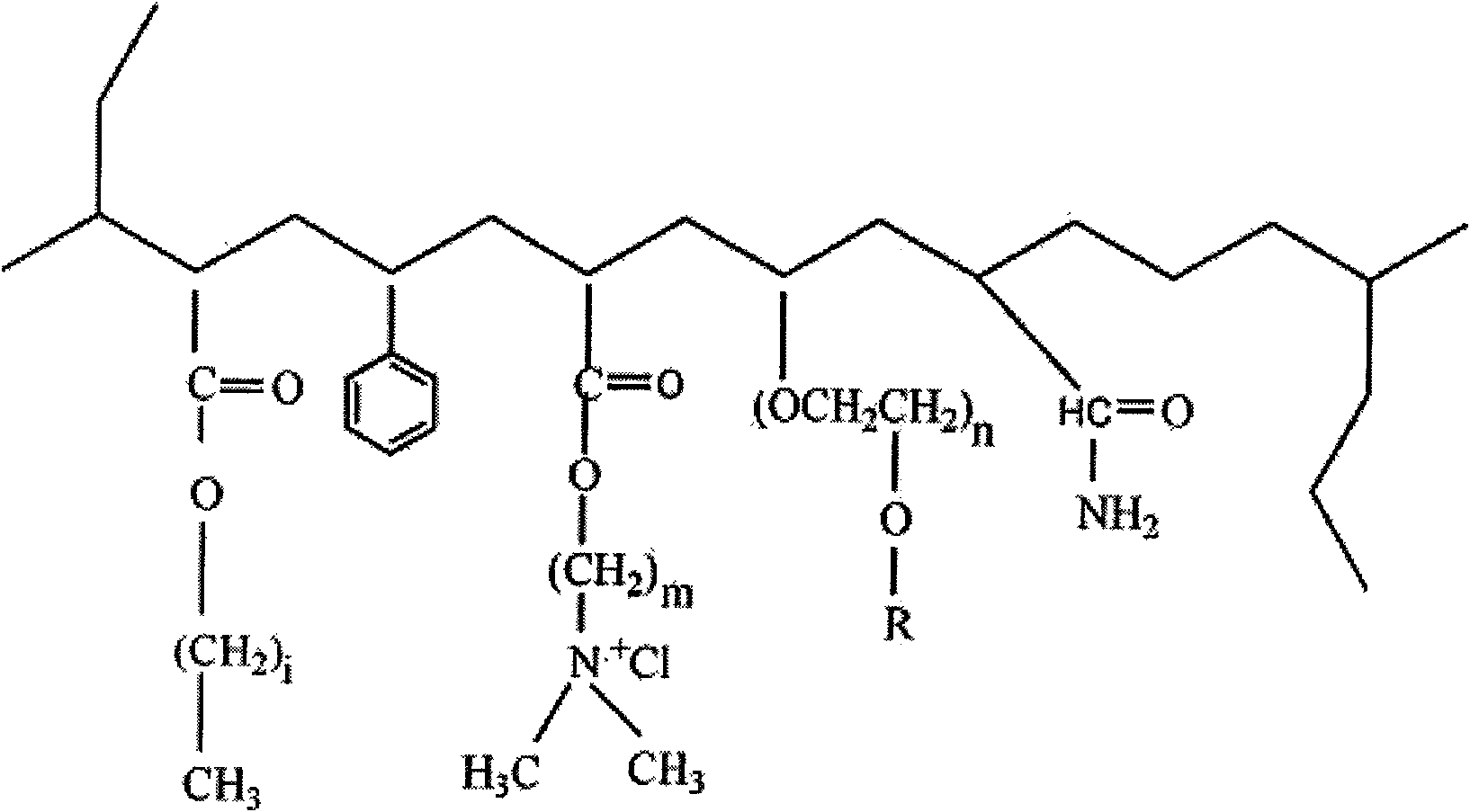

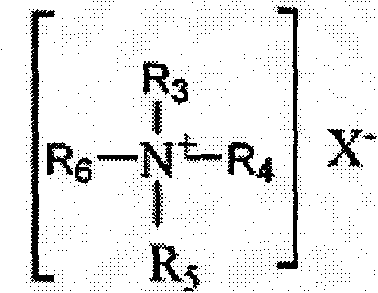

Method used

Image

Examples

Embodiment 1

[0042] Formula: (below in parts by weight)

[0043] ①Methacryloxyethyltrimethylammonium chloride (80%) 35

[0044] ② Methyl acrylate 30

[0045] ③Triphenylethylphenol polyoxyethylene ether (17) methacrylate (60%) 90

[0046] ④Methacrylamide 10

[0047] ⑤Lauryl ammonium bromide 1.5

[0048] ⑥ Fatty alcohol polyoxyethylene ether (EO=7) 0.5

[0049] ⑦2,2'-Azo(2-mimidylpropane)dihydrochloride (V 50) 1.8

[0050] ⑧Dodecanethiol 1.5

[0051] ⑨tert-butyl hydroperoxide 0.5

[0052] ⑩Ascorbic acid 0.5

[0053] water 305

[0054] Process:

[0055] 1. Add 0.5 parts of ⑤, 0.3 parts of ⑦ and 105 parts of water in the raw material components of the above formula into the reaction kettle to mix and dissolve;

[0056] 2. Add 160 parts of ①, ②, ③, ④, ⑤, ⑥, ⑦, ⑧ and water in the raw material components of the above formula to dissolve and pre-emulsify for about 30 minutes;

[0057] 3. Heat the water bath of the reactor to about 80°C, and add one-fifth of the above pre-emulsified liqu...

Embodiment 2

[0063] Formula: (below in parts by weight)

[0064] ①Methacryloxyethyltrimethylammonium chloride (80%) 40

[0065] ②Butyl Acrylate 30

[0066] ③Triphenylethylphenol polyoxyethylene ether (17) methacrylate (60%) 90

[0067] ④Acrylamide 10

[0068] ⑤Lauryl ammonium chloride 2

[0069] ⑥2,2'-Azo(2-mimidylpropane)dihydrochloride (V 50) 1.8

[0070] ⑦Mercaptoethanol 1.5

[0071] ⑧tert-butyl hydroperoxide 0.5

[0072] ⑨Ascorbic acid 0.5

[0073] ⑩ water 305

[0074] Process:

[0075] 1. Add 0.2 parts of ⑤, 0.2 parts of ⑥ and 105 parts of water in the raw material components of the above formula into the reactor to mix and dissolve;

[0076] 2. Add 160 parts of ①, ②, ③, ④, ⑤, ⑥, ⑦ and water in the raw material components of the above formula to dissolve and pre-emulsify for about 30 minutes;

[0077] 3. Heat the water bath of the reactor to about 82°C, and add a quarter of the above pre-emulsified liquid into the reactor for reaction;

[0078] 4. After the blue light appea...

Embodiment 3

[0115] Recipe: the following is the weight percentage

[0116] Polymer dispersant 4%

[0117] Wetting agent S-9 (Dow) 0.5%

[0118] Preservative A28 (Shumei) 0.1%

[0119] Defoamer K3 (Digo) 0.1%

[0120] F5RK (Lily) 12%

[0121] HY100000HP (Shin-Etsu Hydroxyethyl Cellulose) 1%

[0122] VISCOPLUS 3300 (Teco) 2%

[0123] Triethylamine 0-0.5%

[0124] The remainder consists of water balanced to 100%.

[0125] Process:

[0126] 1. Put the polymer dispersant, F5RK, S-9, HY100000HP and water of the raw materials of the above formula 2 into the dispersion kettle, and pre-disperse for 60 minutes;

[0127] 2. Use a horizontal sand mill to grind 2-3 times, use a laser particle size analyzer to detect the fineness, and stop grinding when the average particle size is equal to 0.6-0.8 microns;

[0128] 3. After grinding, the material is transferred to the compounding kettle, add preservative A28 and defoamer K3 to defoam, use thickener 3300 to adjust the viscosity to 3000-4000mpa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com