Preparation method of waterborne polyurethane for synthetic leather

A water-based polyurethane and synthetic leather technology, applied in textiles and papermaking, etc., can solve the problems of low product performance, solvent pollution and high cost, and achieve the effect of improving performance and reducing VOC.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The raw materials utilized in the method of the invention include: diisocyanate, polymer diol, hydrophilic chain extender, small molecule chain extender, acrylate monomer, hydroxy acrylate and neutralizing agent.

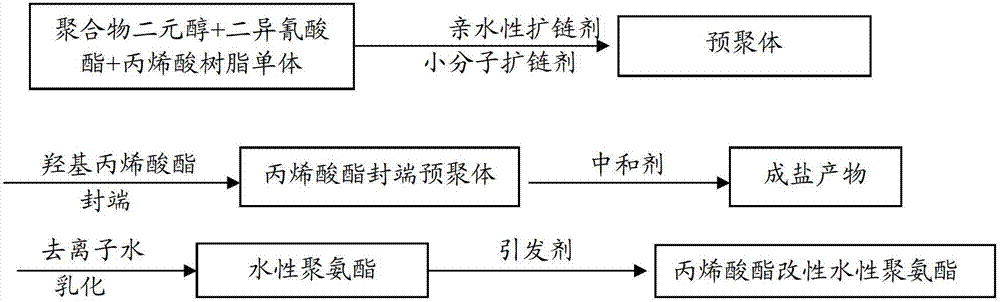

[0030] see figure 1 As shown, the method includes: first mixing diisocyanate, polymer diol, hydrophilic chain extender, and small molecule chain extender, and then adding acrylate monomer, in N 2 React under protection to obtain a polyurethane prepolymer containing hydrophilic groups; then add hydroxyl acrylate monomers to end-cap to obtain double-bond-terminated hydrophilic polyurethane; then add a neutralizer for neutralization, and add deionized water at the same time Emulsification is carried out to obtain a double-bond-terminated water-based polyurethane emulsion; finally, an initiator is added to initiate active double-bond polymerization to obtain the water-based polyurethane for synthetic leather of the present invention.

[0031] The diisocyanate is...

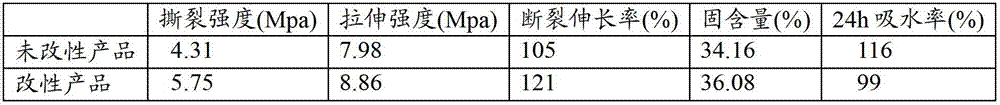

PUM

| Property | Measurement | Unit |

|---|---|---|

| tear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com