Technique for preparing goat chrome-free tanning upper leather

A production process, chrome-free tanning technology, applied in leather dipping, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., can solve problems such as chromium pollution, and achieve The effect of plump leather body, smooth grain surface and safe operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

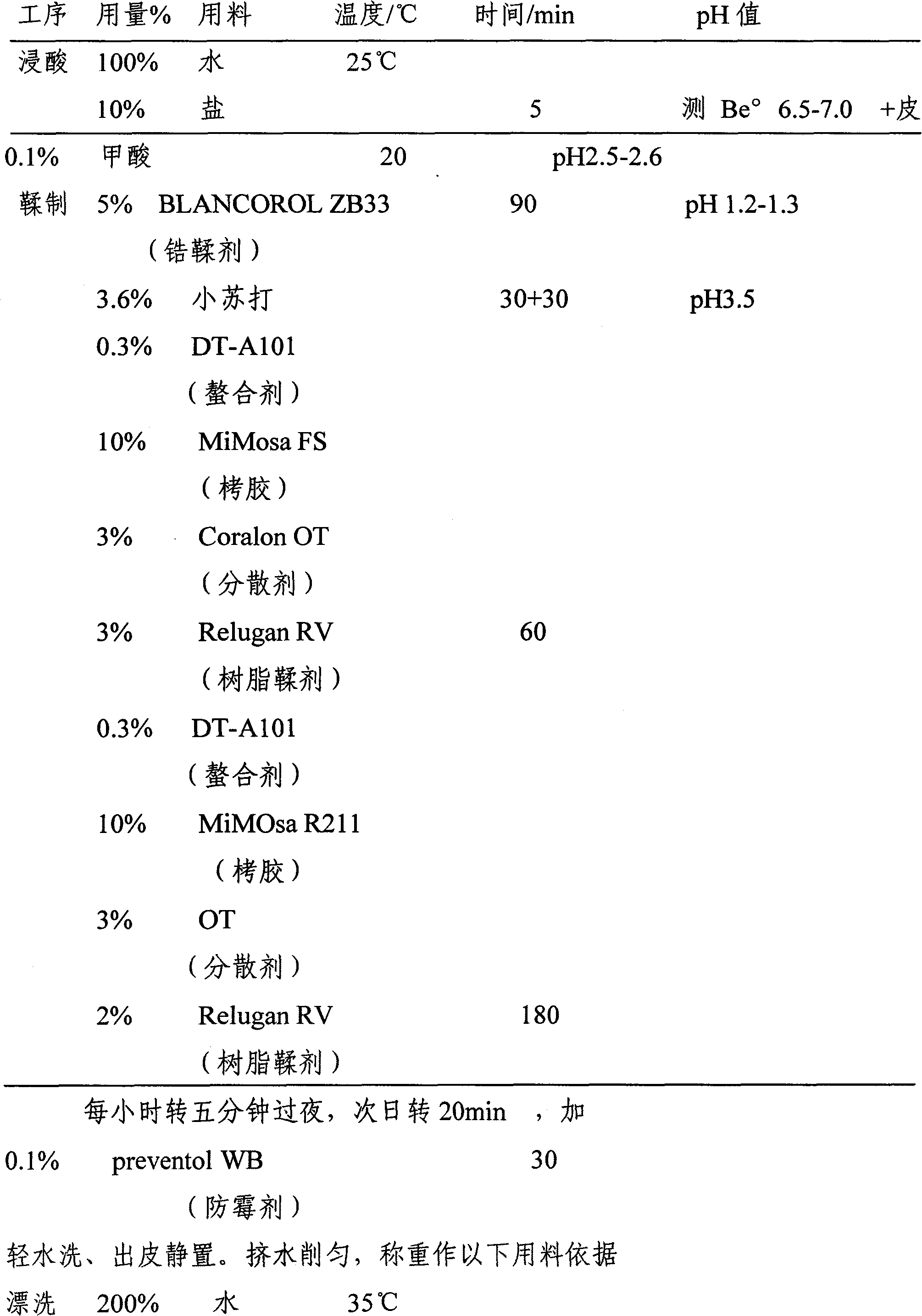

[0029] A production process of goat chrome-free tanned shoe upper leather, which includes pickling, tanning, rinsing, neutralization, retanning, dyeing and oiling, fixing, coloring, washing, peeling, squeezing water the next day, vacuum 50℃ / 70 seconds The finished product can be obtained through the steps of hanging and drying, collecting the skin and leaving it still, restoring moisture, shaking and softening, trimming, stretching the board, and trimming.

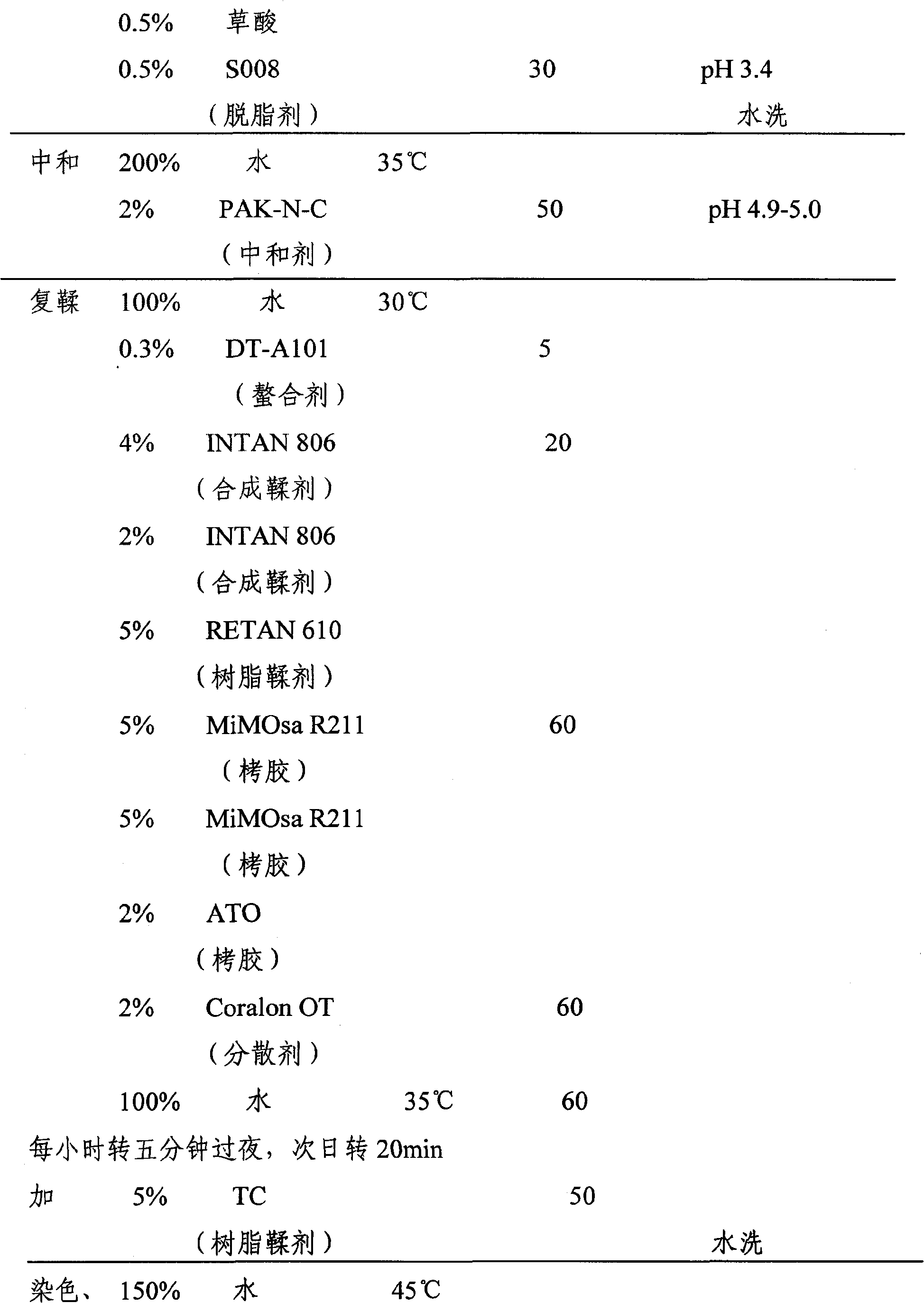

[0030] In the rinsing step, oxalic acid is used to wash off the dirt on the surface of the skin, degreasing agent S008 is added to remove excess oil in the skin, and a neutralizer is added in the neutralization step to increase the pH value of the skin to adapt to the subsequent retanning and filling.

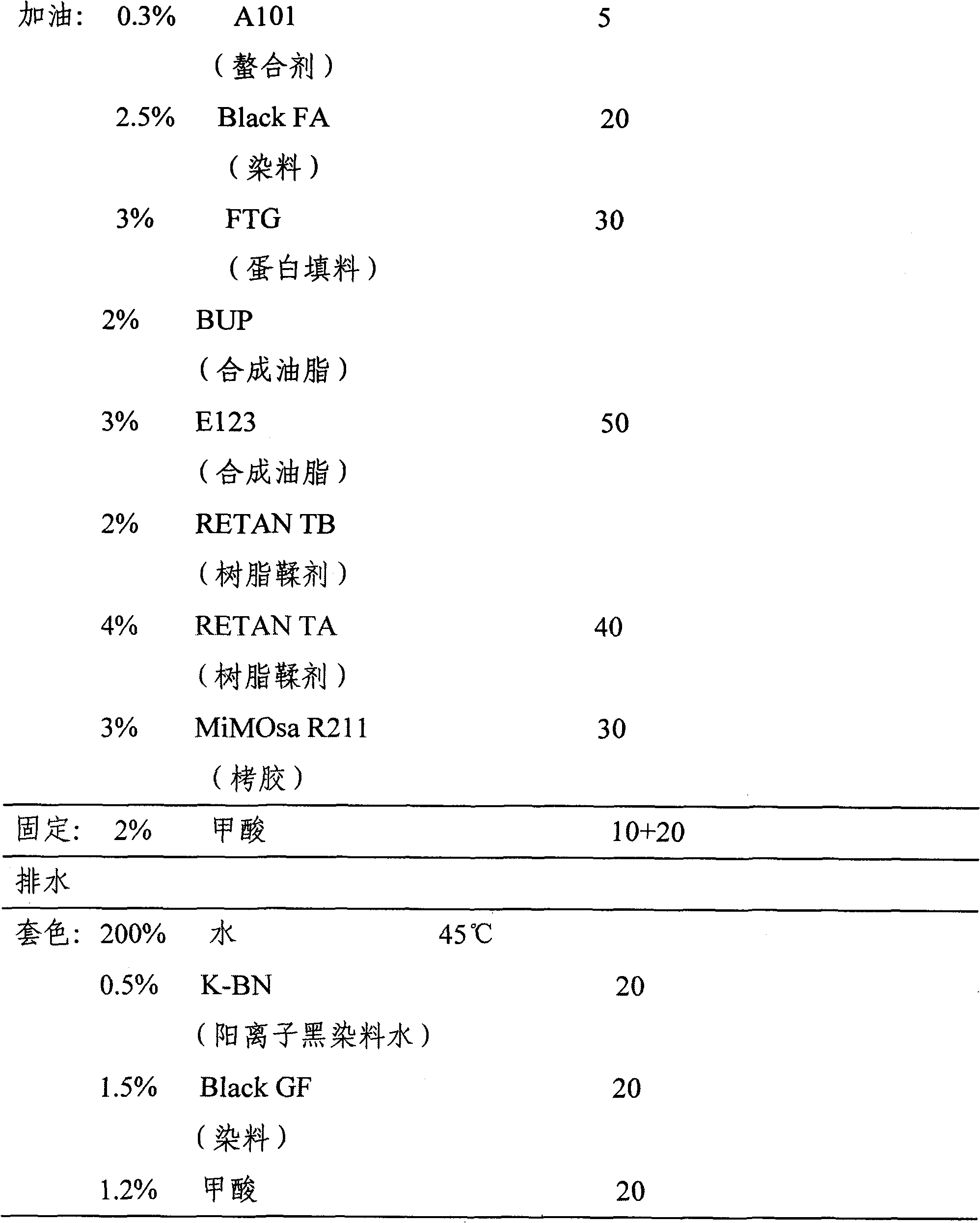

[0031] In the dyeing and oiling step, the purpose of oiling is to improve the softness of the leather body and improve the physical properties of the leather. Before oiling, a chelating agent is added to remove heavy metals in ...

Embodiment 1

[0032] Example 1 (The following percentages are calculated based on the weight percentage of acid peel)

[0033]

[0034]

[0035]

[0036] Washing, peeling, squeezing water the next day, vacuum 50 ℃ / 70 seconds, hanging and drying, peeling and standing, regaining moisture, shaking and stretching, bending, stretching, drying, and trimming are finished products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com