Dry method production line of water-based ecological synthetic leather

A synthetic leather and production line technology, applied in the continuous processing of textile materials, textile material processing, textiles and papermaking, etc., can solve the problems of pinholes, film forming changes, high energy consumption, and achieve excellent quality, production line safety, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below, the present invention will be further described in conjunction with the accompanying drawings and embodiments.

[0034] First of all, the content described in the patent application CN200910152058.7 proposed by the applicant is included in the present invention.

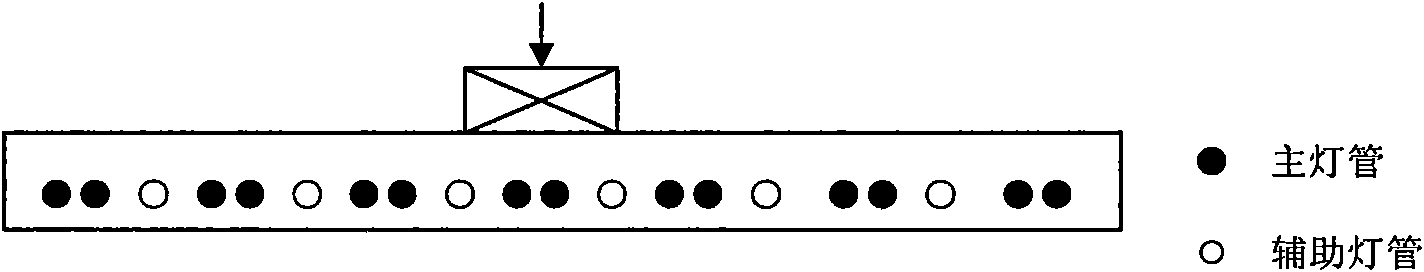

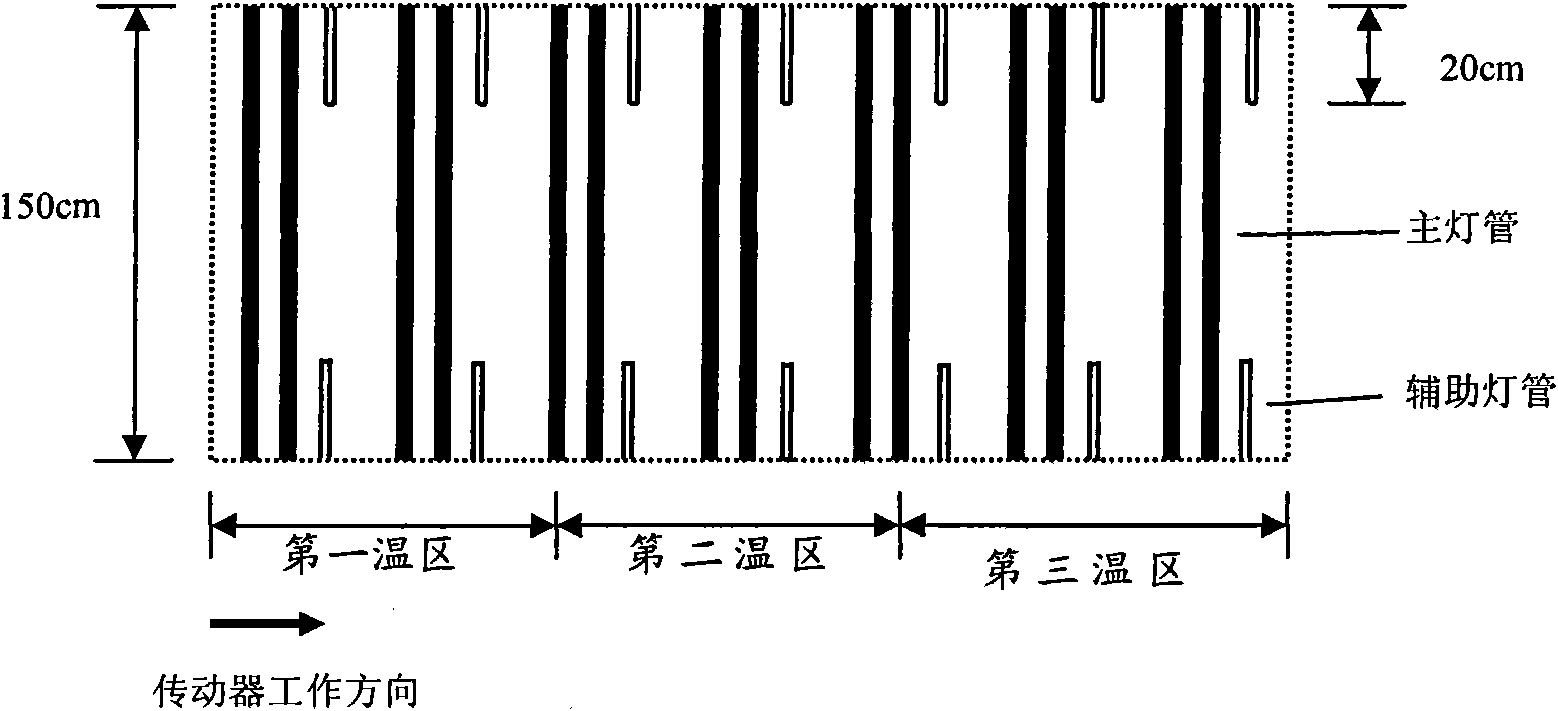

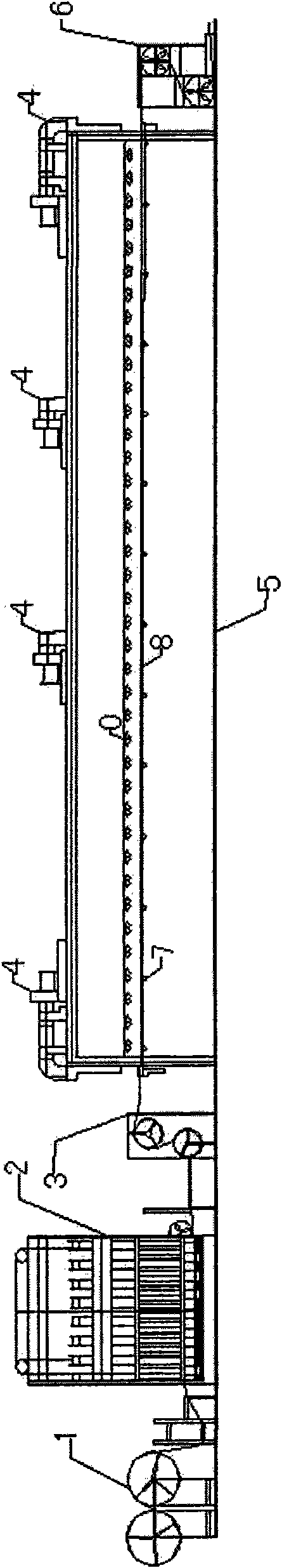

[0035] According to one embodiment of the present invention, a dry-process production line for water-based ecological synthetic leather is provided. In order to meet the drying requirements of water-based synthetic leather, in this embodiment, a mid-wave infrared radiation device is specially used as the heat source for the drying system of the dry-process production line of water-based ecological synthetic leather. Mid-wave infrared heating is a dual heating method of radiation and heat conduction. The medium-wave infrared light (generally referring to the infrared light with a wavelength between 2.5 and 40 μm) emitted by the infrared radiator (light source) is absorbed by the water in the water-based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com