Method for calibrating electrically controlled diesel engine

A technology of diesel engine and calibration method, which is applied in the field of calibration of electronically controlled diesel engines to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

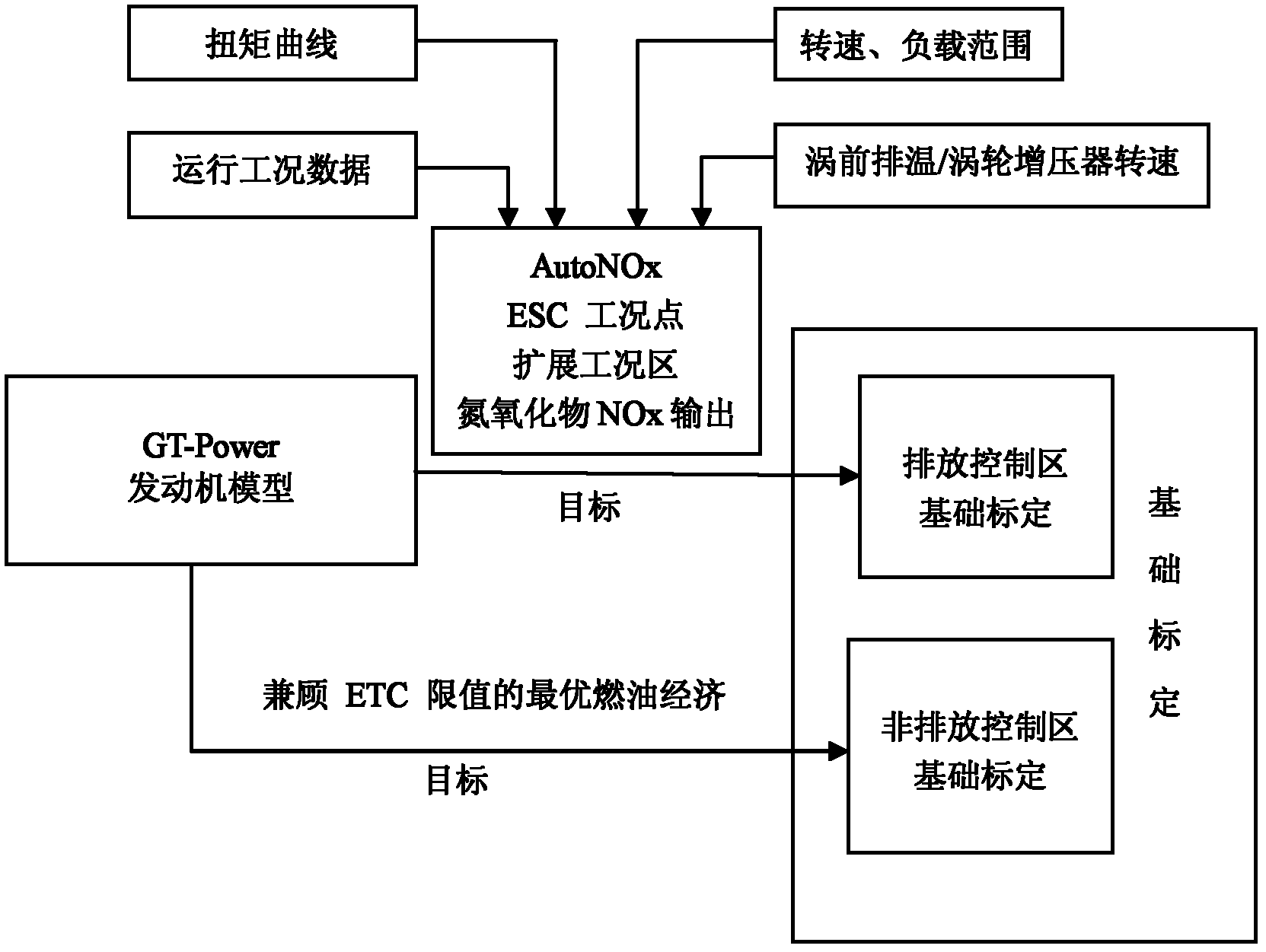

[0043] A calibration method for an electronically controlled diesel engine, such as figure 1 As shown, the design value of nitrogen oxide emission at each working point in the emission control area of the electronically controlled diesel engine is calculated by AutoNOx, and then the design value is used as the emission target of the GT-power engine model, so as to obtain the calibration of the diesel engine.

[0044] Under the conditions of meeting the ETC (European Transient Cycle) test emission limit and optimal fuel economy, the calibration of the non-emission control area is obtained through the GT-Power engine model. Since emissions are not considered in non-emission control areas, there is no emission limit and no need to calculate the emission of nitrogen oxides.

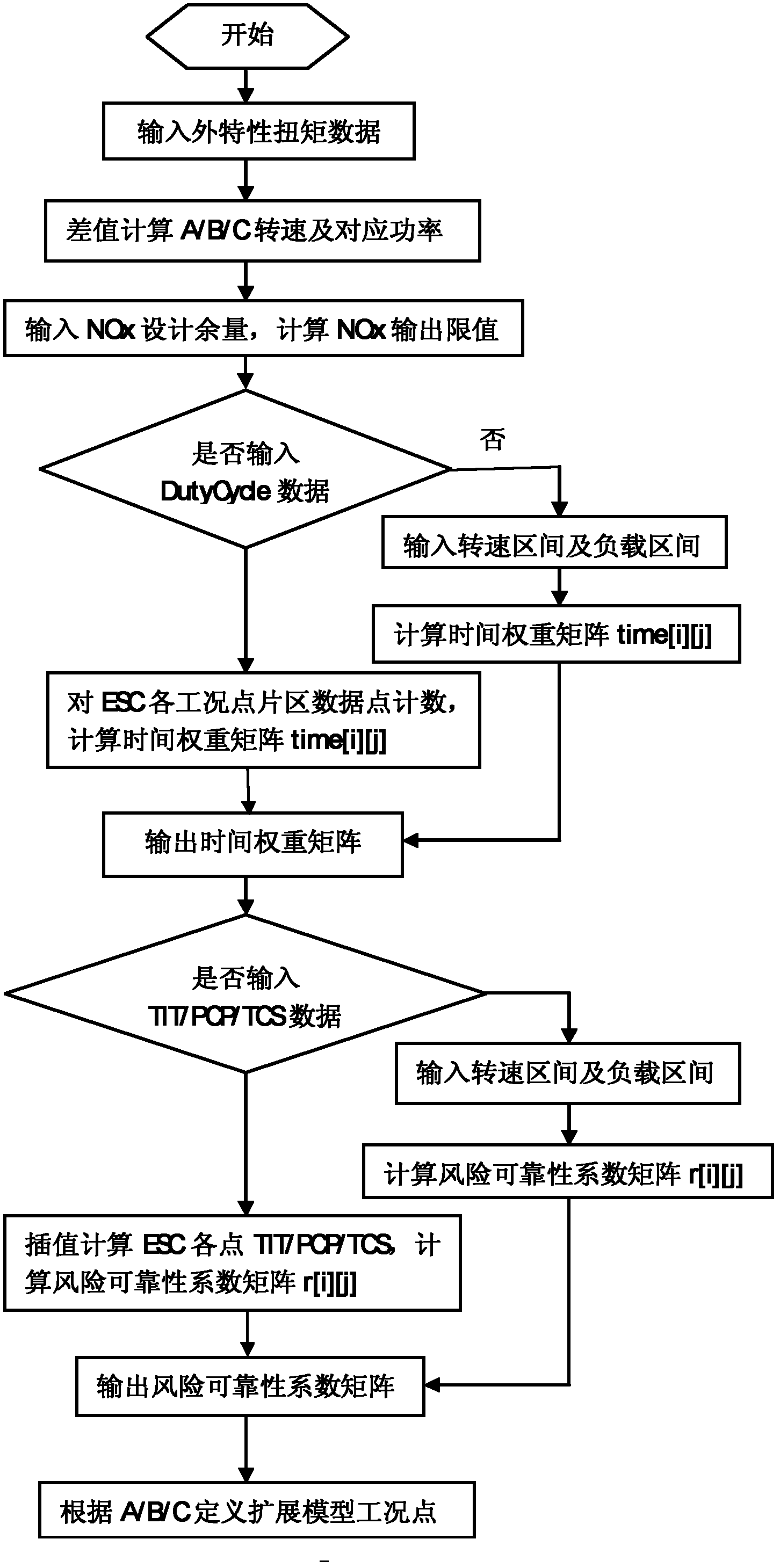

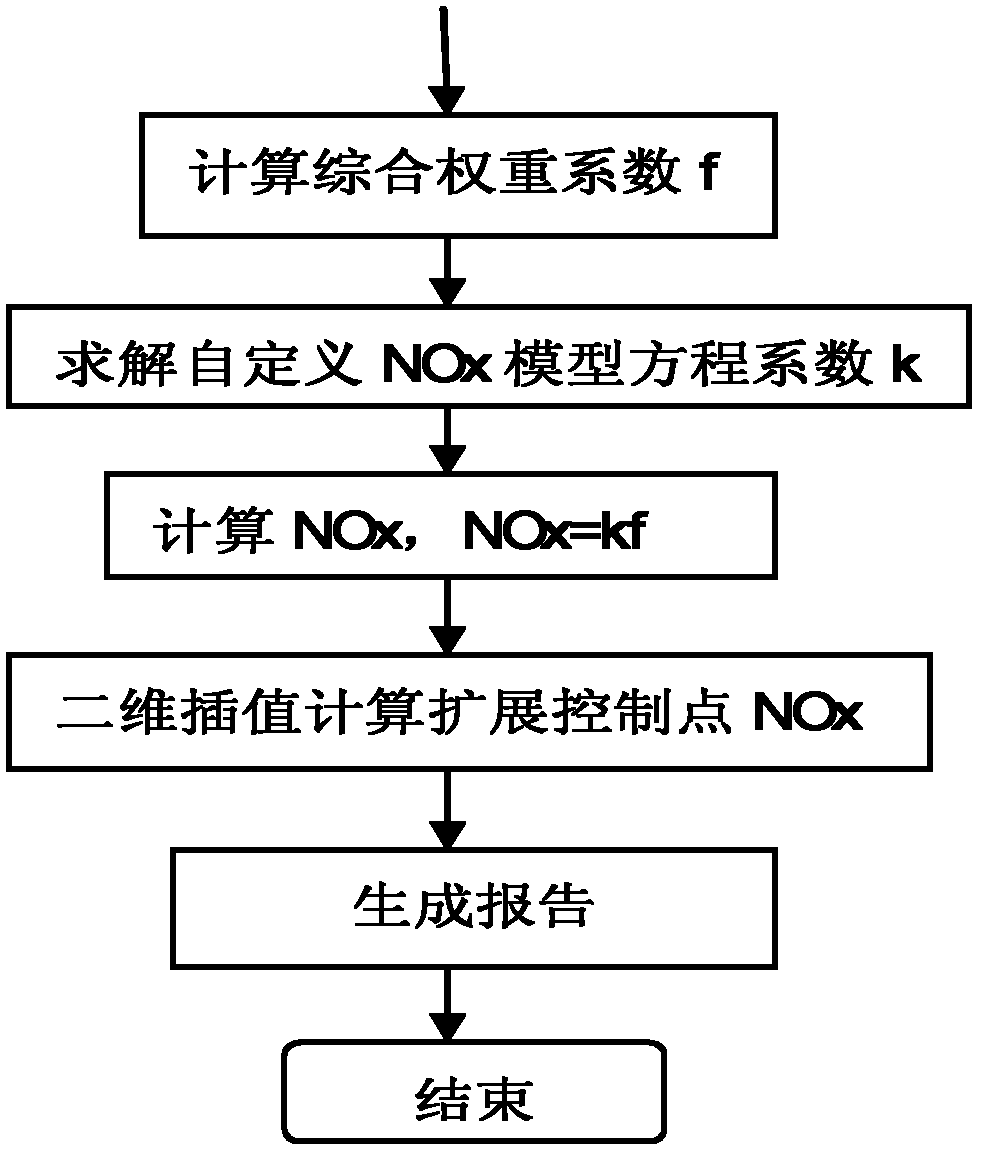

[0045] The method for calculating the design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com