Sublevel retreating type two-fluid composite grouting construction method for deep foundation pit of sandy gravel stratum

A construction method and technology of deep foundation pit, applied in infrastructure engineering, excavation, construction, etc., can solve problems such as inability to install sleeve valve pipe, difficulty in extubation, long construction period, etc., to overcome difficulties in extubation, shorten construction period, The effect of high working torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

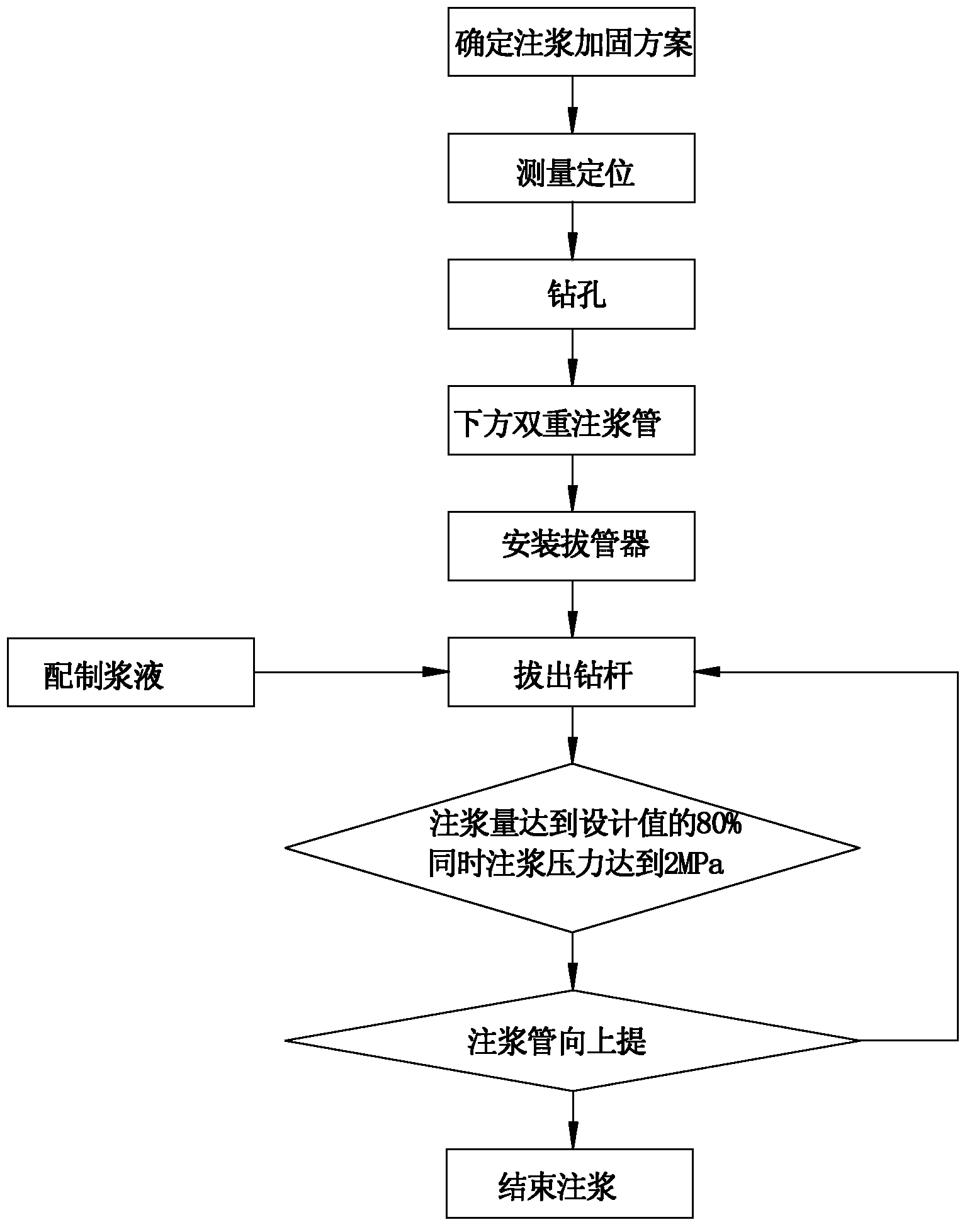

[0035] The step-back two-liquid composite grouting construction method of the deep foundation pit in the sand and pebble formation of the present invention, its construction process and operating points are as follows figure 1 shown.

[0036] 1) Determine the grouting reinforcement scheme

[0037] The grouting holes are distributed in the middle and outside of the retaining piles. There are two rows in total. The spacing between the holes is 900mm, and the spacing between the two rows is 600mm. Purpose: A total of 1,138 grouting holes are to be set up with φ89mm drill pipes. The drilling depth is from the current ground elevation (46.65m) to 0.5m below the conglomerate layer. The conglomerate layer elevation is 10.62m. The volum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com