Generator

A generator and generator stator technology, which is applied to motors, electric vehicles, electrical components, etc., can solve the problems of inconvenient installation and use in specific occasions, low power generation efficiency, complex structure, etc., and achieves light weight, simple structure, and application range. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

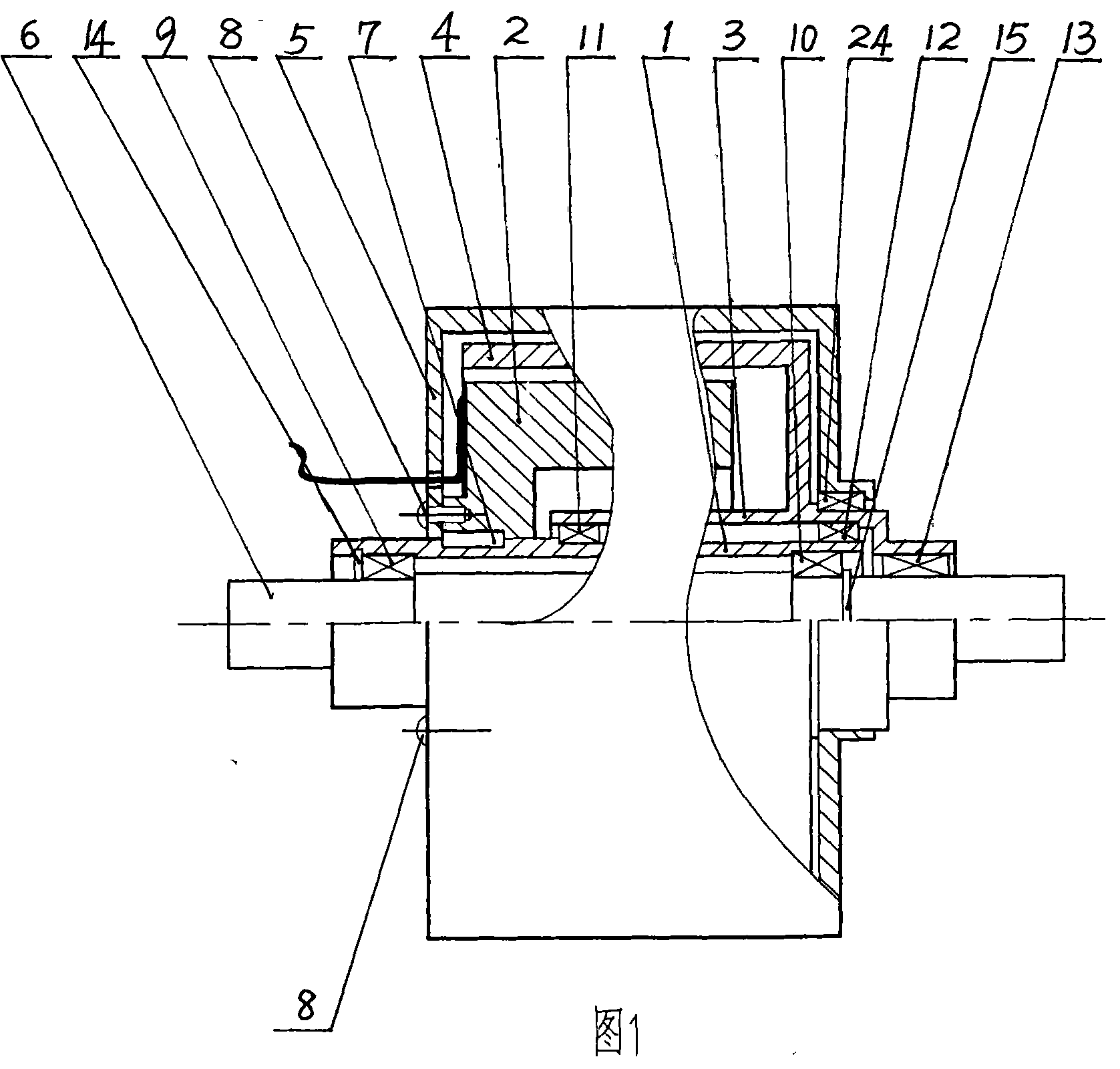

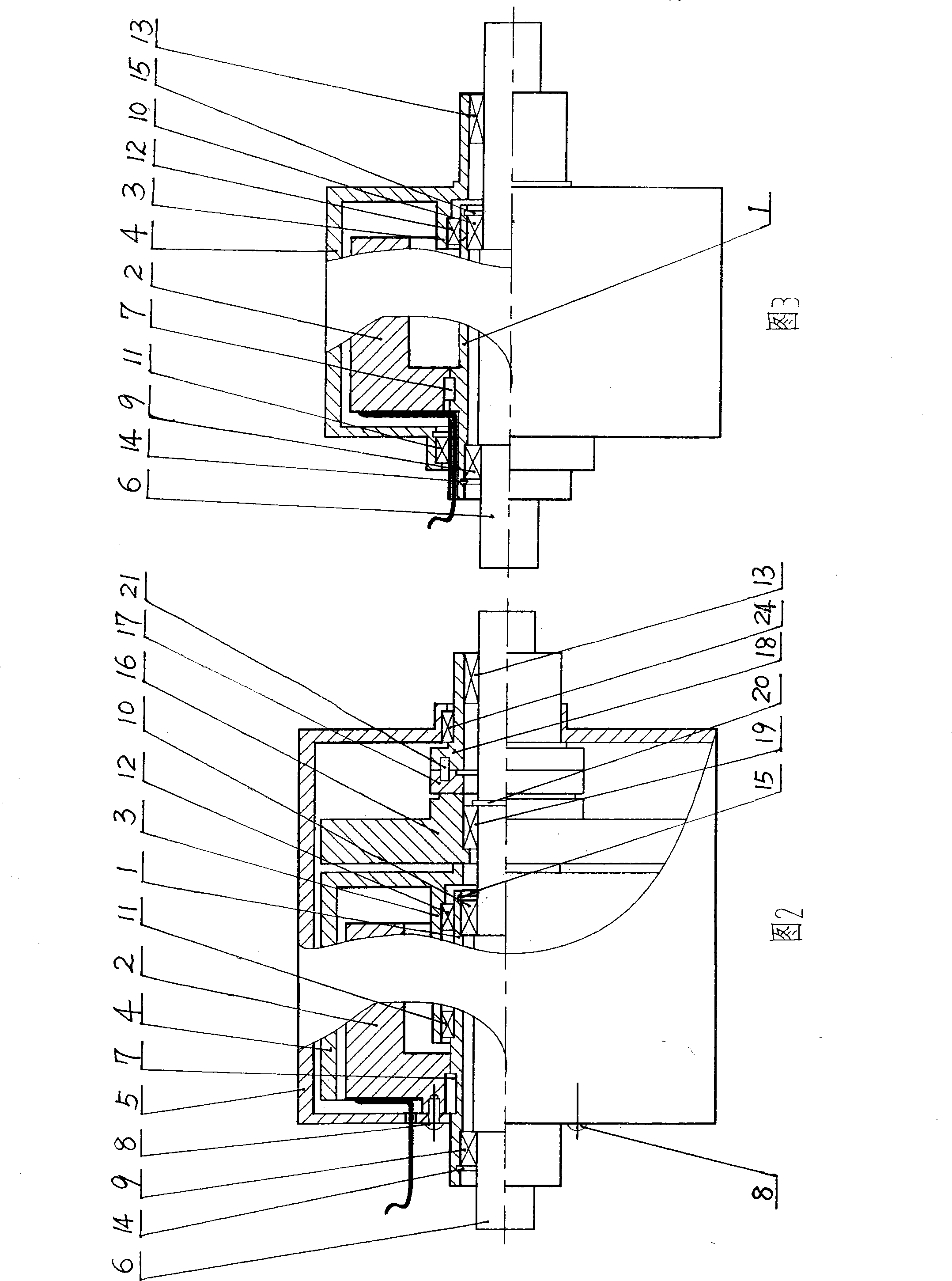

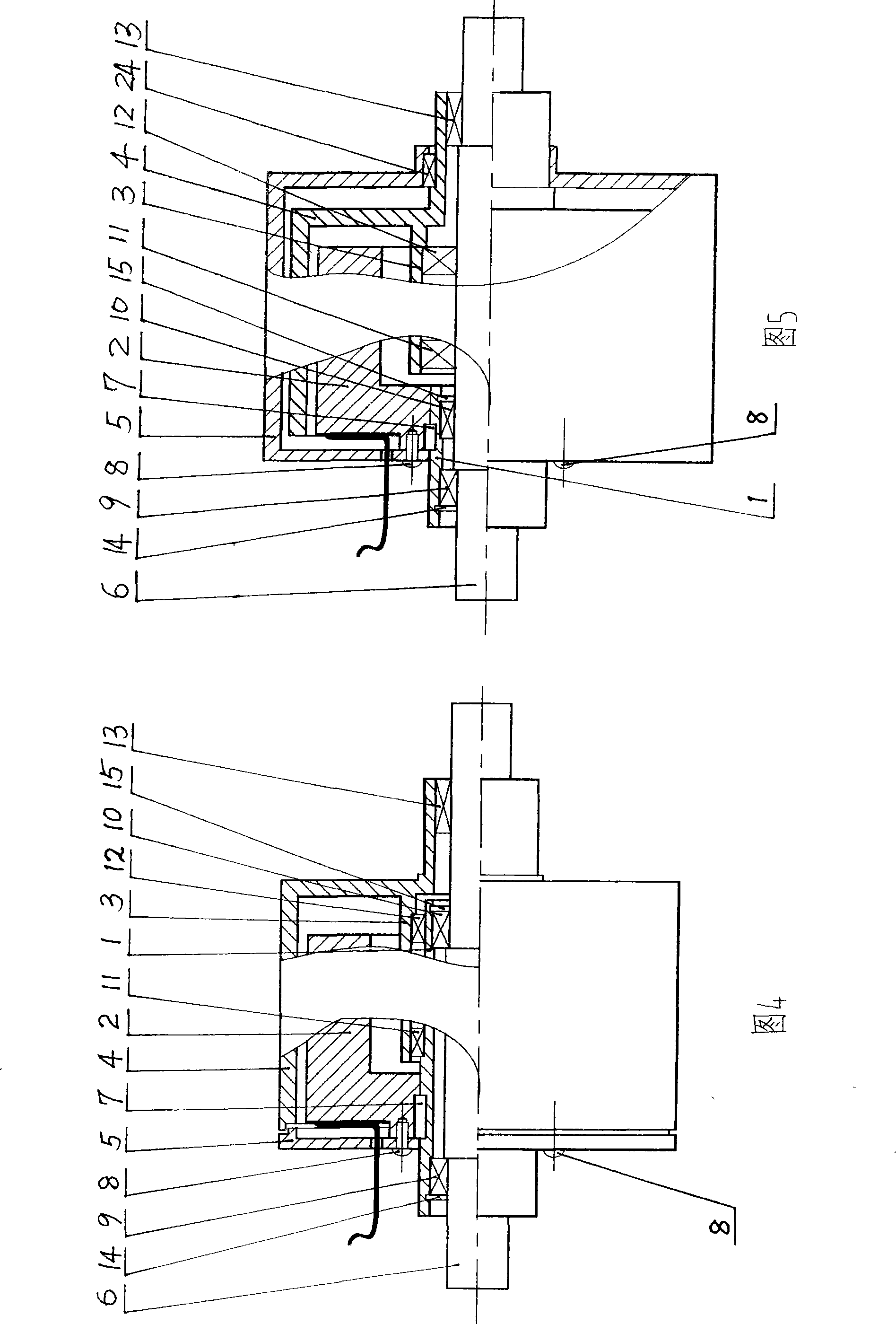

[0026] Embodiment 1: Take wind power generation as an example for illustration.

[0027] Such as figure 1 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown: the generator stator shaft 1 and the rotor shaft 3 are hollow shafts, the generator rotor shaft 3 and the generator rotor 4 are fixedly connected, the generator stator shaft 1 is fixedly connected with the generator stator 2, and is fixed by a pin placed axially 7 is fixed, the generator stator 2 and the stator casing 5 are fixedly connected by bolts 8, one end of the stator casing 5 is supported by a bearing 24 on the output side of the generator rotor shaft 3, and the generator stator shaft 1 and the rotor shaft 3 have a through shaft 6. The through shaft 6 is respectively supported in the generator stator shaft 1 through two bearings 9 and 10 at both ends of the generator stator shaft 1. The bearings 9 and 10 are axially fixed by two retaining springs 14 and 15 respectively. The generator rotor 4. The two bea...

Embodiment 2

[0029] Embodiment 2: Take electric bicycle pedal power generation as an example for illustration.

[0030] Such as figure 1 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 8 As shown: the generator stator shaft 1 and the rotor shaft 3 are hollow shafts, the generator rotor shaft 3 and the generator rotor 4 are fixedly connected, the generator stator shaft 1 is fixedly connected with the generator stator 2, and is fixed by a pin placed axially 7 is fixed, the generator stator 2 and the stator casing 5 are fixedly connected by bolts 8, one end of the stator casing 5 is supported by a bearing 24 on the output side of the generator rotor shaft 3, and the generator stator shaft 1 and the rotor shaft 3 have a through shaft 6. The through shaft 6 is respectively supported in the generator stator shaft 1 through two bearings 9 and 10 at both ends of the generator stator shaft 1. The bearings 9 and 10 are axially fixed by two retaining springs 14 and 15 respectively. The ...

Embodiment 3

[0033] Embodiment 3: Taking an electric bicycle as an example, the generator is changed to be driven by a motor for illustration.

[0034] Such as figure 1 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 8 Shown: the alternator is changed into electric motor drive. When the corresponding current is passed into the coil of the generator stator 2, the generator rotor 4 rotates, and the output end of the generator rotor shaft 3 drives the sprocket to rotate, and the electric bicycle advances, but at this time, due to the generator stator shaft 1 and the rotor shaft 3 It is a hollow shaft, the generator stator shaft 1 and the rotor shaft 3 have a through shaft 6, and one end of the generator rotor shaft 3 and the through shaft 6 is fixed with a first bearing 13, and the first bearing 13 adopts a one-way bearing (or a One-way clutch instead of using) disengages, the through shaft 6 does not turn, then the pedal crank and the pedals fixed on the two ends of the throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com