Linear motor driven ship model forced rolling device

A linear motor, ship model technology, applied in the direction of electromechanical devices, electric components, ship construction, etc., can solve the problems of unguaranteed motor accuracy, poor mechanical efficiency, low accuracy, etc., and achieve good engineering application prospects and economic value, equipment The effect of small ruler and accurate slider movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

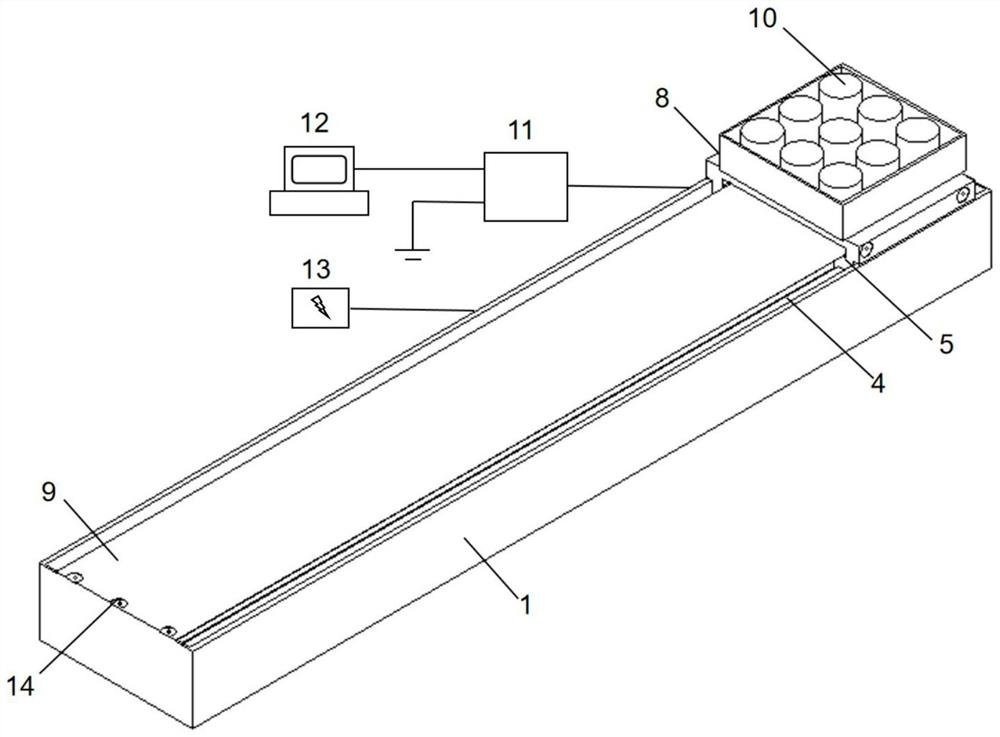

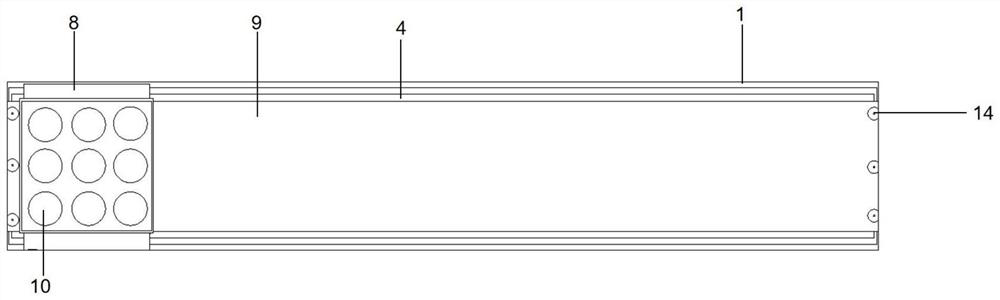

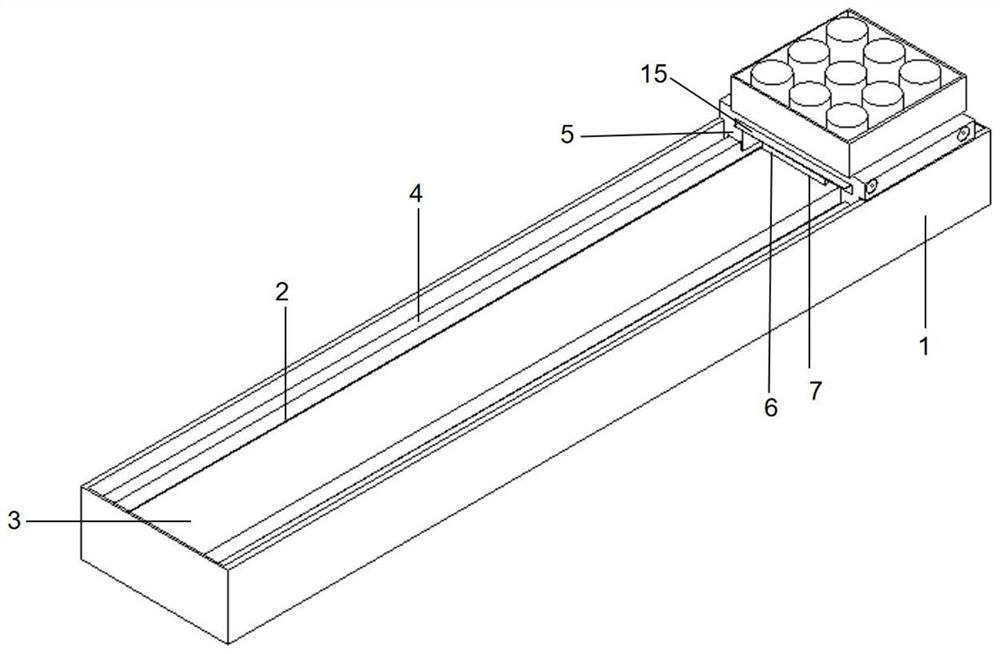

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] according to Figure 1 to Figure 4 , the linear motor-driven ship model forced rolling device of the present invention mainly includes the main body of the rolling device and the upper computer system, specifically including: the main body shell 1, the main body bottom plate 2, the stator 3, the slide rail 4, the slide rail connection buckle 5, the mover Box 6, mover 7, load slider 8, main body cover plate 9, weight 10, control box 11, host computer 12, power supply 13, assembly bolt 14, clearance 15.

[0028] The principle of the linear motor-driven ship model forced rolling device of the present invention is powered by a power supply, wherein the stator 3, the mover box 6 and the mover 7 form a linear motor module, and the linear motor module drives the load slider 8 on the slide rail 4 Do reciprocating motion, through the control system to control the speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com