Method for drying cut tobacco and device for predicting moisture content of outlet cut tobacco

A technology for moisture content and cut tobacco, which is applied in the fields of tobacco, tobacco preparation, and tobacco processing, can solve the problems of not meeting design requirements, the moisture content of finished cut tobacco cannot be kept stable, and the stability of cigarette quality is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

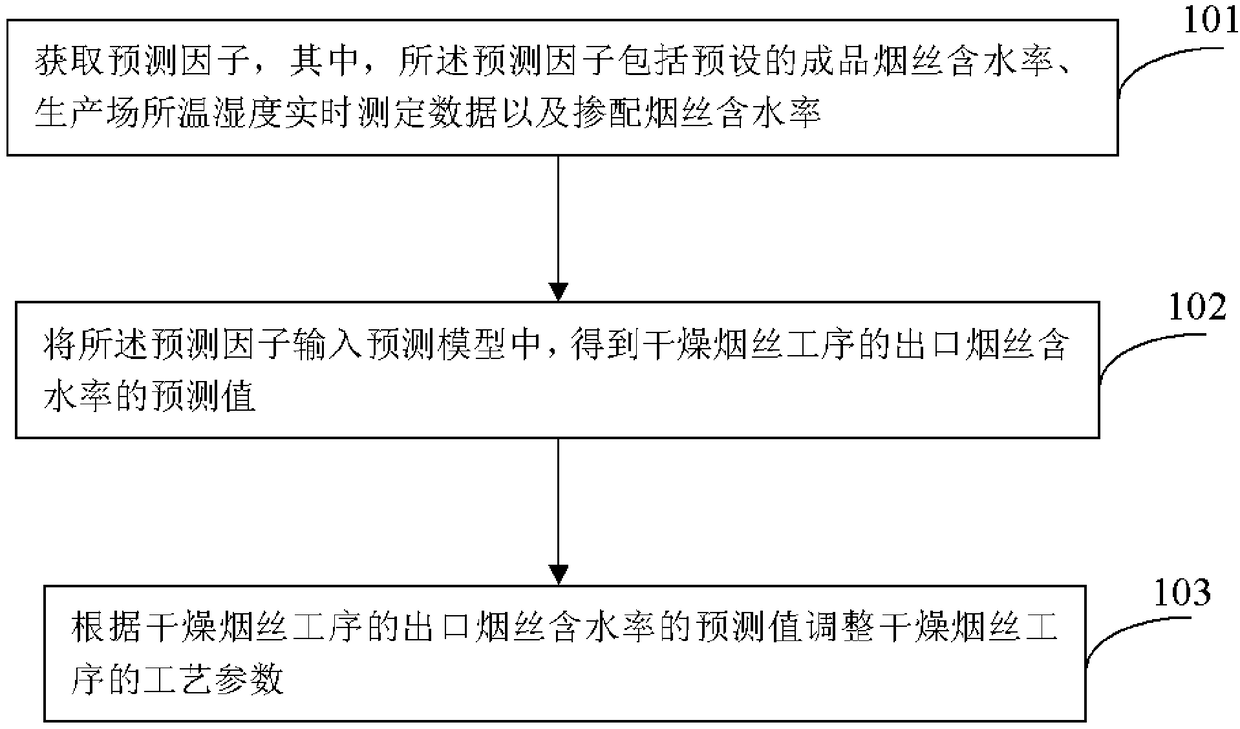

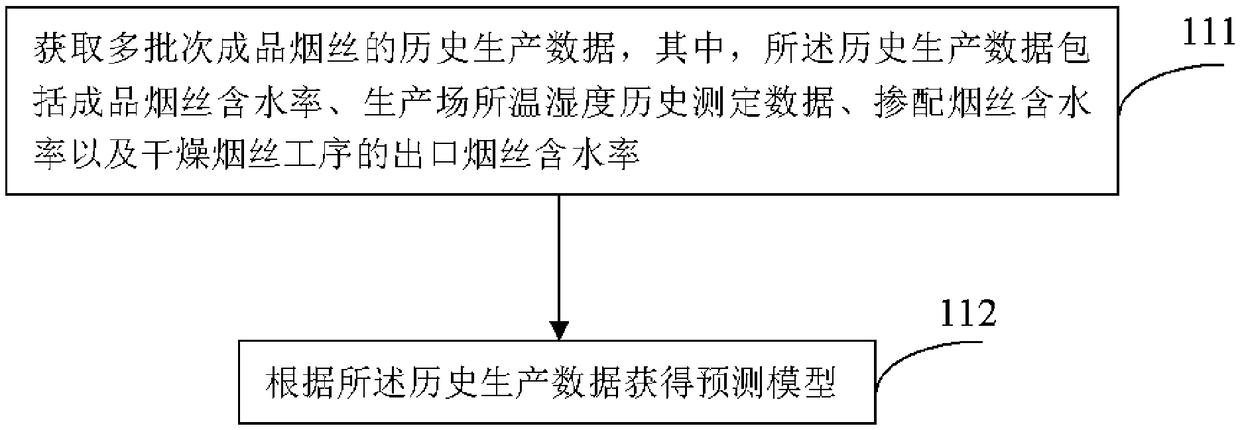

Method used

Image

Examples

Embodiment

[0132] use figure 1 , 3 In the method and device, the moisture content of the two batches of exported cut tobacco in April 2017 was predicted, and the dried cut tobacco was implemented in the system sent to the dry cut tobacco process, and the production of finished cut tobacco was continued; at the same time, according to the traditional method, manual The moisture content of the two batches of exported shredded tobacco was determined empirically, sent to the system to dry the shredded tobacco, and continued to complete the production of the finished shredded tobacco; the results are shown in Table 1-2.

[0133] Among them, the absolute error is the absolute difference between the actual value of the moisture content of the finished tobacco and the design value of the moisture content of the finished tobacco (12.0%), and the accuracy is the result of dividing the absolute difference by the design value of the moisture content of the finished tobacco (12.0%). The actual value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com