Cigarette paper for thin cigarette and application of cigarette paper

A technology for cigarette paper and cigarettes, which is applied in the fields of special paper, paper, papermaking, etc., can solve the problems that cannot be directly applied to slim cigarettes, and achieve the effects of stable cigarette smoking quality, simple requirements, and improved matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

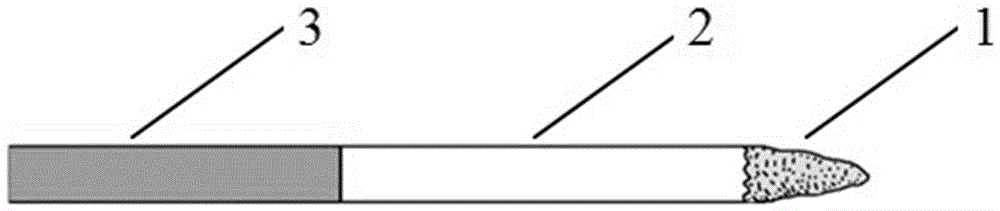

Image

Examples

Embodiment 1

[0020] The cigarette paper for slim cigarettes provided in this example, in terms of mass percentage, has a pulp material ratio of 53.5% wood pulp fiber, 12% hemp pulp fiber, 30% calcium carbonate, and 1.0% starch , 1.0% guar gum, 2.0% magnesium hydroxide whiskers, 0.5% aluminum hydroxide whiskers;

[0021] The prepared pulp is sequentially subjected to short-cycle homogenization, wire forming, pressing, and drying to form base paper.

[0022] In the base paper sizing section, the potassium citrate aqueous solution with a mass concentration of 15% is evenly coated on the front side of the base paper (the non-tobacco contact surface, and the reverse side is the contact tobacco surface) as a combustion accelerant with a mass concentration of 15%, so that the combustion accelerant content in the finished cigarette paper is 2.5 %; Finally, after drying, coiling, rewinding, slitting, packaging and other processes, it is the finished product of cigarette paper for slim cigarettes. ...

Embodiment 2

[0024] The cigarette paper for slim cigarettes provided in this example, in terms of mass percentage, has a pulp material ratio of 50% wood pulp fiber, 12% hemp pulp fiber, 30% calcium carbonate, and 1.0% starch , 1.0% guar gum, 4.5% magnesium hydroxide whiskers, 1.5% aluminum hydroxide whiskers;

[0025] The prepared pulp is sequentially subjected to short-cycle homogenization, wire forming, pressing, and drying to form base paper.

[0026] In the base paper sizing section, the potassium citrate aqueous solution with a mass concentration of 15% is evenly coated on the front side of the base paper (the non-tobacco contact surface, and the reverse side is the contact tobacco surface) as a combustion accelerant with a mass concentration of 15%, so that the combustion accelerant content in the finished cigarette paper is 2.5 %; Finally, after drying, coiling, rewinding, slitting, packaging and other processes, it is the finished product of cigarette paper for slim cigarettes.

Embodiment 3

[0028] The cigarette paper for slim cigarettes provided in this example, in terms of mass percentage, has a pulp material ratio of 47% wood pulp fiber, 12% hemp pulp fiber, 30% calcium carbonate, and 1.0% starch , 1.0% guar gum, 6.0% magnesium hydroxide whiskers, 3.0% aluminum hydroxide whiskers;

[0029] The prepared pulp is sequentially subjected to short-cycle homogenization, wire forming, pressing, and drying to form base paper.

[0030] In the base paper sizing section, the potassium citrate aqueous solution with a mass concentration of 15% is evenly coated on the front side of the base paper (the non-tobacco contact surface, and the reverse side is the contact tobacco surface) as a combustion accelerant with a mass concentration of 15%, so that the combustion accelerant content in the finished cigarette paper is 2.5 %; and then evenly coated on the front side of the base paper (non-tobacco contact side, contact tobacco side is the reverse side); finally after drying, coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com