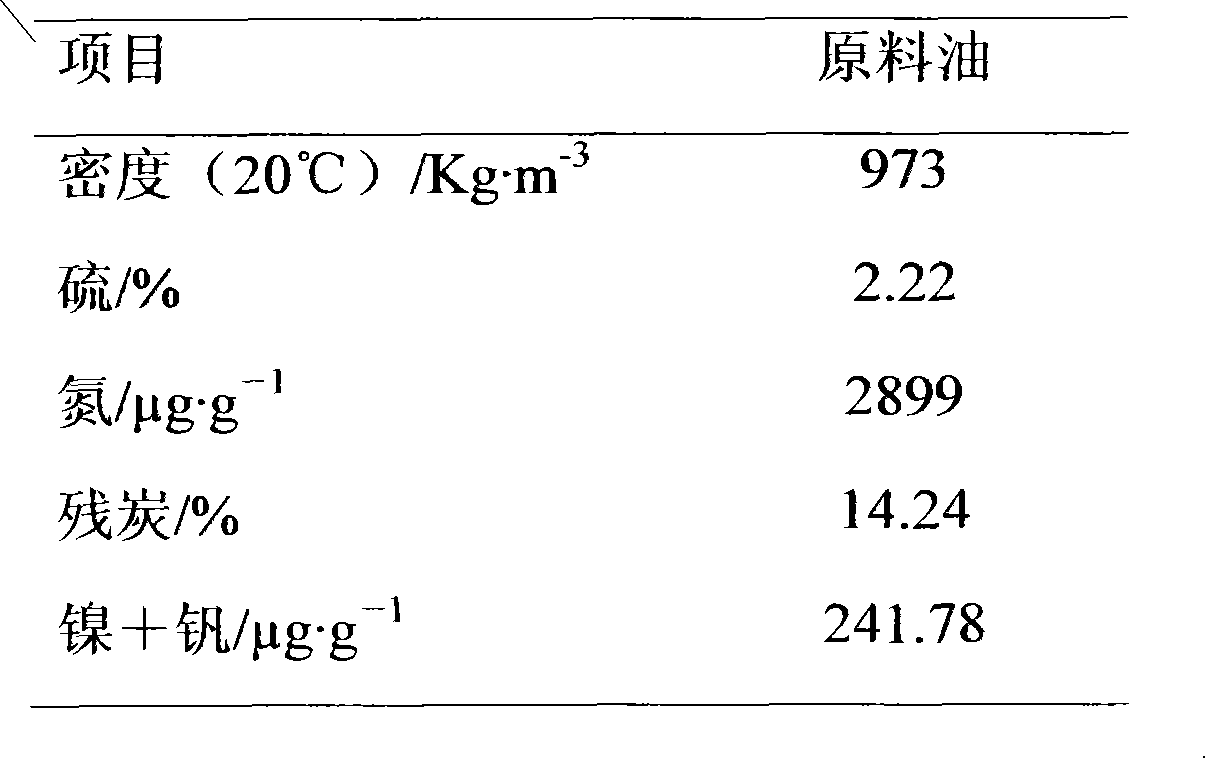

Residual oil hydrogenation catalyst and preparation method and use thereof

A technology for residual oil hydrogenation and catalysts, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. Hydrogen process and other problems to achieve the effect of increasing cracking performance, simple modification method, and increasing acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

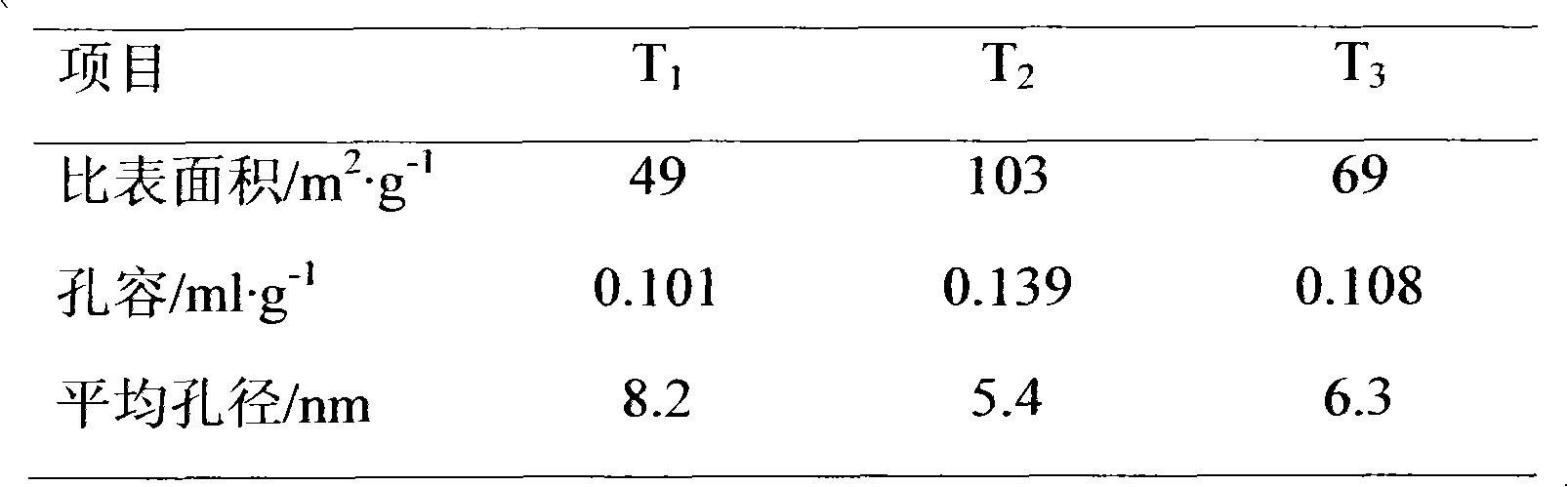

Embodiment 1

[0017] Roast kaolin raw soil in a high-temperature furnace at a temperature of 600°C and keep the temperature for 12 hours. After cooling, weigh 200 grams and put it in a container. Add 400ml of 2mol / L nitric acid and 400ml of 2mol / L citric acid, and heat for reaction. The reaction temperature at 60°C, the reaction time is 8h, then washed, filtered and dried to obtain modified kaolin T 1 .

[0018] Take by weighing 600 grams of pseudo-boehmite dry glue (containing alumina 79wt%), add 23.7 grams of carbon black, 9.48 grams of fennel powder, and add modified kaolin T 1 7.10 grams, mixed evenly, then added 17.7 grams of ammonia water, 720 grams of distilled water, kneaded and extruded into strands, then dried at 120°C for 2 hours, and calcined at 800°C for 3 hours to obtain carrier A.

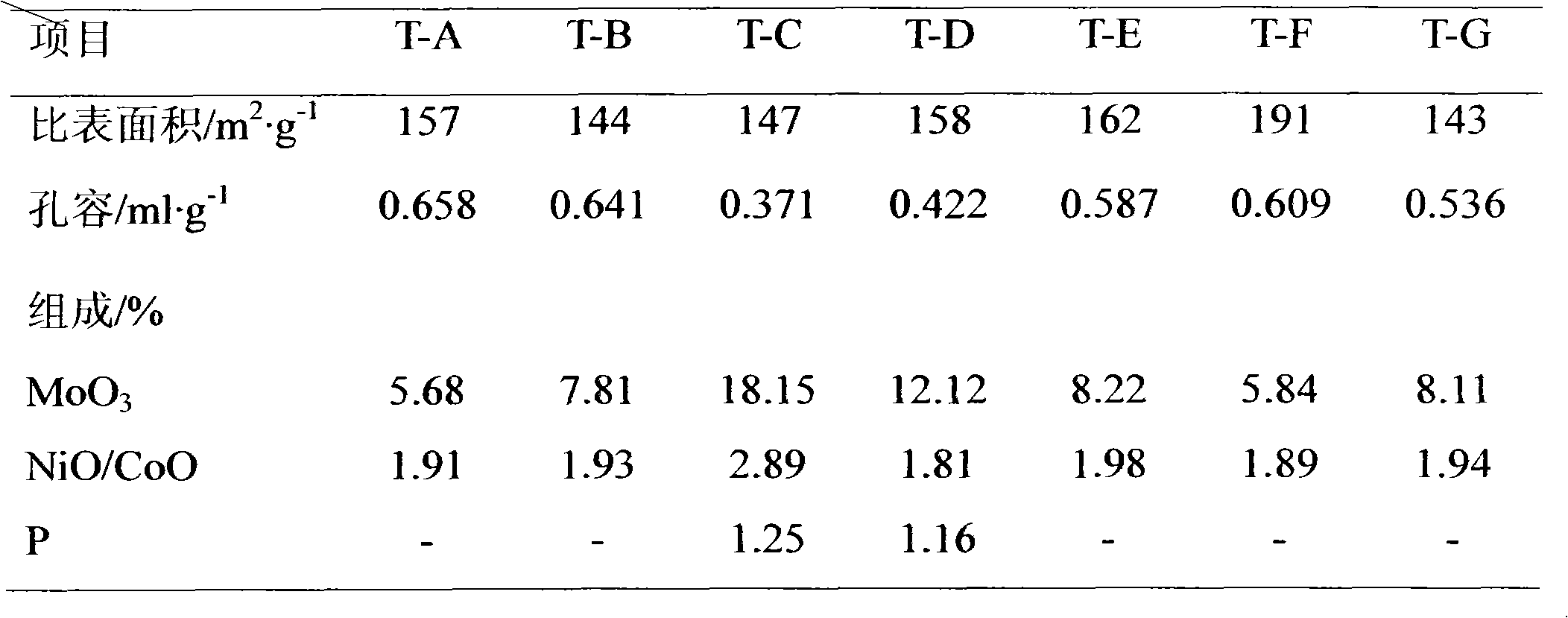

[0019] Weigh 82.56 grams of ammonium heptamolybdate, add 900 ml of 12% ammonia water, then add 37.46 g of basic nickel carbonate and stir until completely dissolved, adjust the volume of the solu...

Embodiment 2

[0021] The method is the same as in Example 1, except that the amount of kaolin added is 27.88 g, dried at 120° C. for 2 hours, and calcined at 900° C. for 2 hours to obtain carrier B.

[0022] Weigh 168.80 g of ammonium heptamolybdate, add 1400 ml of 12% ammonia water, then add 57.44 g of basic nickel carbonate and stir until completely dissolved, adjust the volume of the solution to 1500 ml with ammonia water to obtain solution L-2. Saturated carrier B was impregnated with L-2 solution, dried at 100°C for 6h, and calcined at 520°C for 3h to obtain catalyst T-B.

Embodiment 3

[0024] The method is the same as in Example 1, except that the amount of kaolin added is 121.72 g, dried at 120° C. for 2 hours, and calcined at 900° C. for 1 hour to obtain carrier C.

[0025] Weigh 144.90g of phosphoric acid, add 1400ml of distilled water, then sequentially add 354.19g of molybdenum oxide and 93.27g of basic cobalt carbonate, heat and stir until completely dissolved, then adjust the solution to 1500ml with distilled water to obtain solution L-3. Saturated carrier C was impregnated with L-3 solution, dried at 120°C for 2 hours, and calcined at 480°C for 3 hours to obtain catalyst T-C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com