Low permeability coal bed liquid nitrogen freeze thawing cracking permeability increasing method

A freeze-thaw, coal seam technology, applied in earth-moving drilling, gas discharge, mining fluids, etc., can solve the problems of high technical cost, difficult drug delivery, difficult pipe down, high coal seam stress, high gas and low permeability, etc. The effect of large humidity range and expansion of freeze-thaw cracking range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

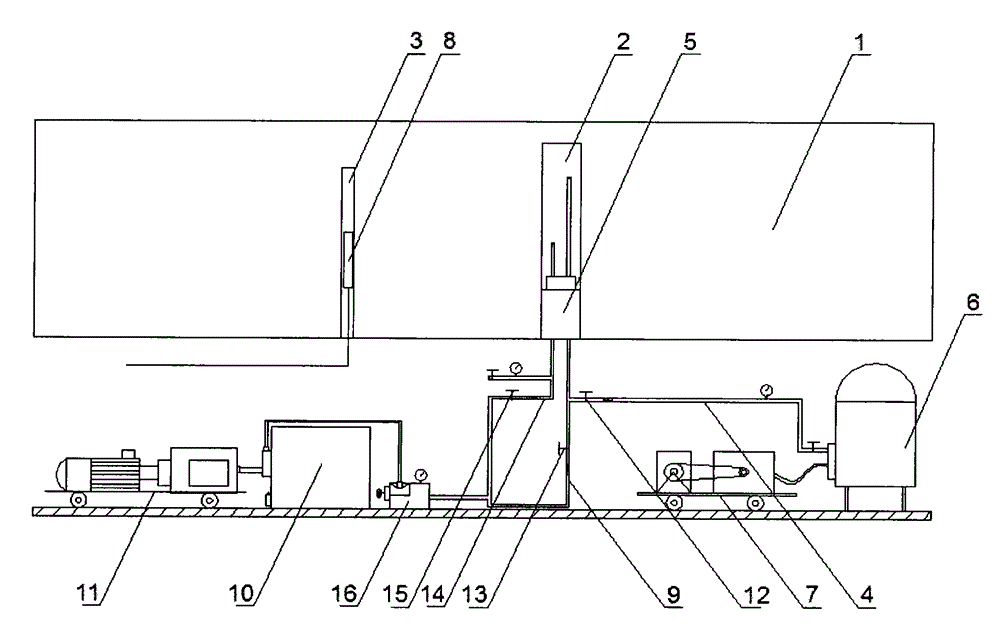

[0031] The low-permeability coal seam liquid nitrogen freeze-thaw cracking anti-permeability method comprises the following steps:

[0032] a) Drilling a freeze-thaw borehole 2 and a monitoring borehole 3 to the low-permeability coal seam 1 in the underground roadway, the diameter of the freeze-thaw borehole 2 is 80mm, and the depth of the hole is 26m. The minimum distance to monitor the inner wall of borehole 3 is 5m;

[0033] b) arrange the first pipeline 4, extend one end of the first pipeline 4 into the freeze-thaw borehole 2, and seal the freeze-thaw borehole 2 with the sealing device 5 at the same time, and place the first pipeline The other end of the road 4 is connected to a nitrogen generating separation device 6, which is used to produce liquid nitrogen, and the nitrogen generating separation device 6 is connected to a liquid nitrogen injection pump 7;

[0034] c) Install a temperature monitoring device 8 in the monitoring borehole 3, after the temperature monitored...

Embodiment 2

[0040] Compared with Embodiment 1, in this embodiment, after step b) and before step c), step c1) is also implemented: arranging the first pipeline branch 9, connecting one end of the first pipeline branch 9 with The first pipeline 4 communicates, and the other end is connected with the water tank 10, and the water tank 10 is connected with the water injection pump 11, and the first pipeline 4 and the first pipeline branch 9 are respectively installed with first The control valve 12 and the second control valve 13 are used to switch between injecting liquid nitrogen and injecting water into the freeze-thaw borehole 2 .

[0041]After step c1) and before step d), step d1) is also included: closing the first control valve 12, opening the second control valve 13, starting the water injection pump 11, and starting to pass through the first pipeline The branch 9 injects water into the freeze-thaw borehole 2, and monitors in real time whether there is water seepage in the monitoring ...

Embodiment 3

[0047] Compared with Embodiment 1, this embodiment also implements step c2) after step b) and before step c): arranging the second pipeline 14, and extending one end of the second pipeline 14 into the freeze-thaw In the borehole 2, the other end is connected with the water tank 10, the water tank 10 is connected with the water injection pump 11, and a third control valve 15 is installed in the second pipeline 14 for feeding the freeze-thaw drill. Well 2 is switched between liquid nitrogen injection and water injection. After step c2), before step d), step d2) is also implemented: close the first control valve 12, open the third control valve 15, start the water injection pump 11, and start to pass through the second The pipeline 14 injects water into the freeze-thaw borehole 2, and monitors in real time whether there is water seepage in the monitoring borehole 3. After confirming that there is water seepage, continue to inject water for 50 minutes, then stop the water injectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Hole depth | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com