Textile cloth wetting device for textile use

A wetting technology for textile fabrics, which is applied in the field of wetting devices for textile fabrics, can solve the problems of wetting influence on textile fabrics, fabric wrinkles, etc., and achieve the effects of improving the wetting effect, increasing the wetting area, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

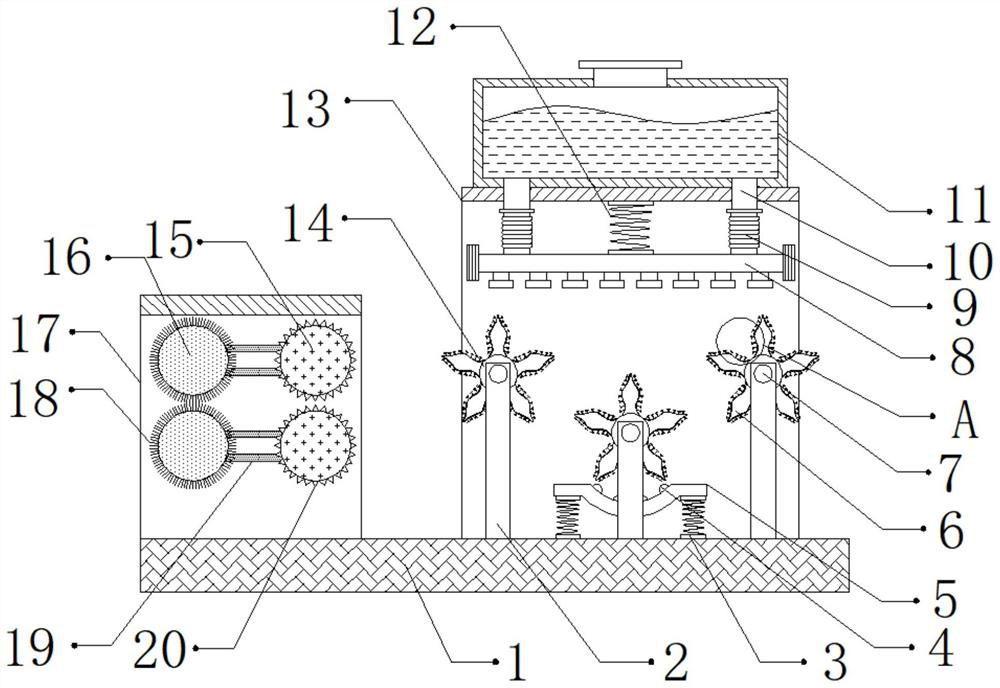

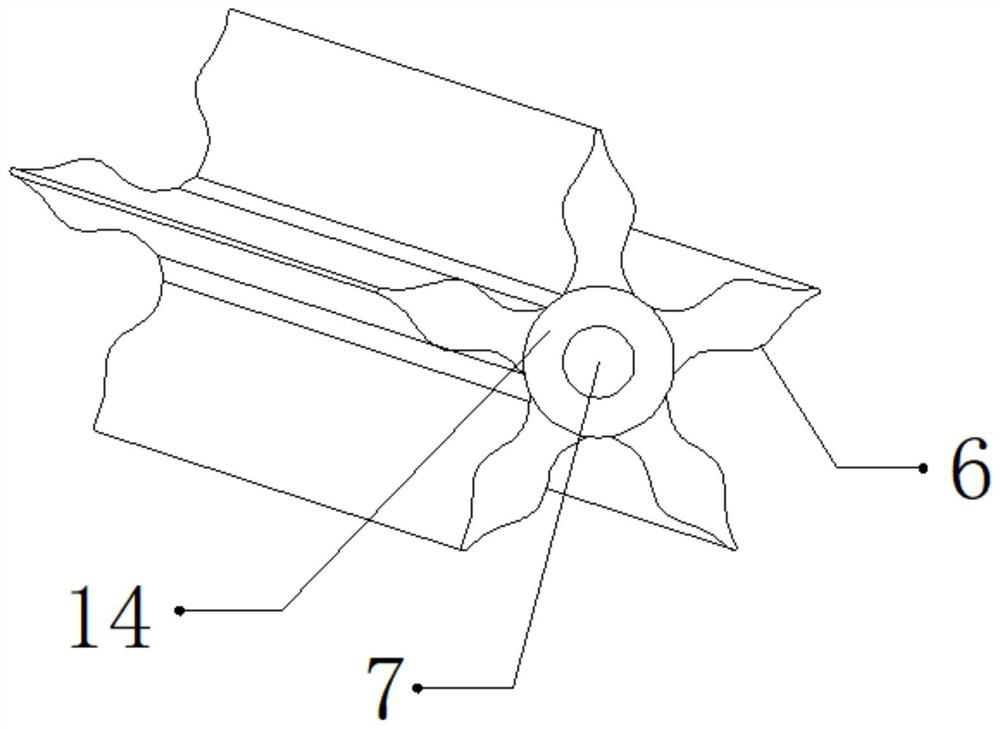

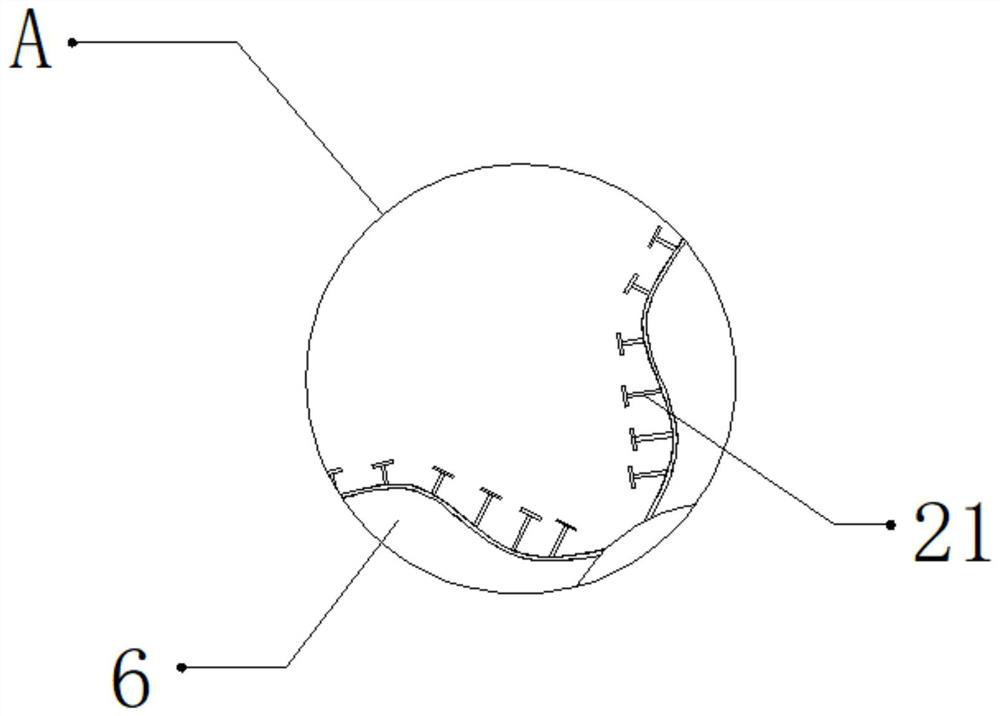

[0029] refer to Figure 1-4 , a wetting device for weaving textile fabrics, comprising a fixed seat 1, one side of the top outer wall of the fixed seat 1 is connected with a fixed frame 13 by bolts, and the top outer wall of the fixed frame 13 is connected with a water storage tank 11 by bolts, and the water storage tank 11 The top outer wall is provided with a water inlet, and both sides of the bottom outer wall of the fixed frame 13 are provided with drain pipes 10, and the bottom outer walls of the two drain pipes 10 are connected with bellows 9 through flanges, and the bottom outer walls of the two bellows 9 are passed through The flange is connected with a conduit 8, and the bottom outer wall of the conduit 8 is provided with an atomizing nozzle, and one side of the top outer wall of the fixed seat 1 is connected with a plurality of fixed rods 2 of different heights by bolts, and the outer wall of the fixed rod 2 is connected with a rotating shaft in rotation. 7. The oute...

Embodiment 2

[0038] refer to Figure 5, a wetting device for weaving textile fabrics. Compared with Embodiment 1 in this embodiment, a plurality of third springs 24 are connected to one side of the top outer wall of the fixing base 1 by bolts, and the third spring 24 is connected to the supporting frame 17. Through the bolt connection, before the cloth is wetted, the movement of the textile cloth drives the support frame 17 to vibrate up and down, so that the dust adhering to the textile cloth is processed by the vibration of the third spring 24 .

[0039] Working principle: When in use, the textile cloth that needs to be wetted passes through the cleaning roller, the rotating roller 15 and the supporting sheet 6 in sequence, and clean water is filled into the inside of the water storage tank 11 through the water inlet, so that the clean water is transported to the conduit 8 through the bellows 9 inside, and then spray water mist to the surface of the textile cloth through the atomizing no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com