Tunnel hole distributing explosion method

A technology of tunnel and hole layout, applied in blasting and other directions, can solve the problems of difficulty in forming light blasting effect, disturbance of contour surrounding rock, increase of dangerous rock dropping, etc., to achieve safe and stable blasting effect, excellent comprehensive construction benefit, secondary lining The effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

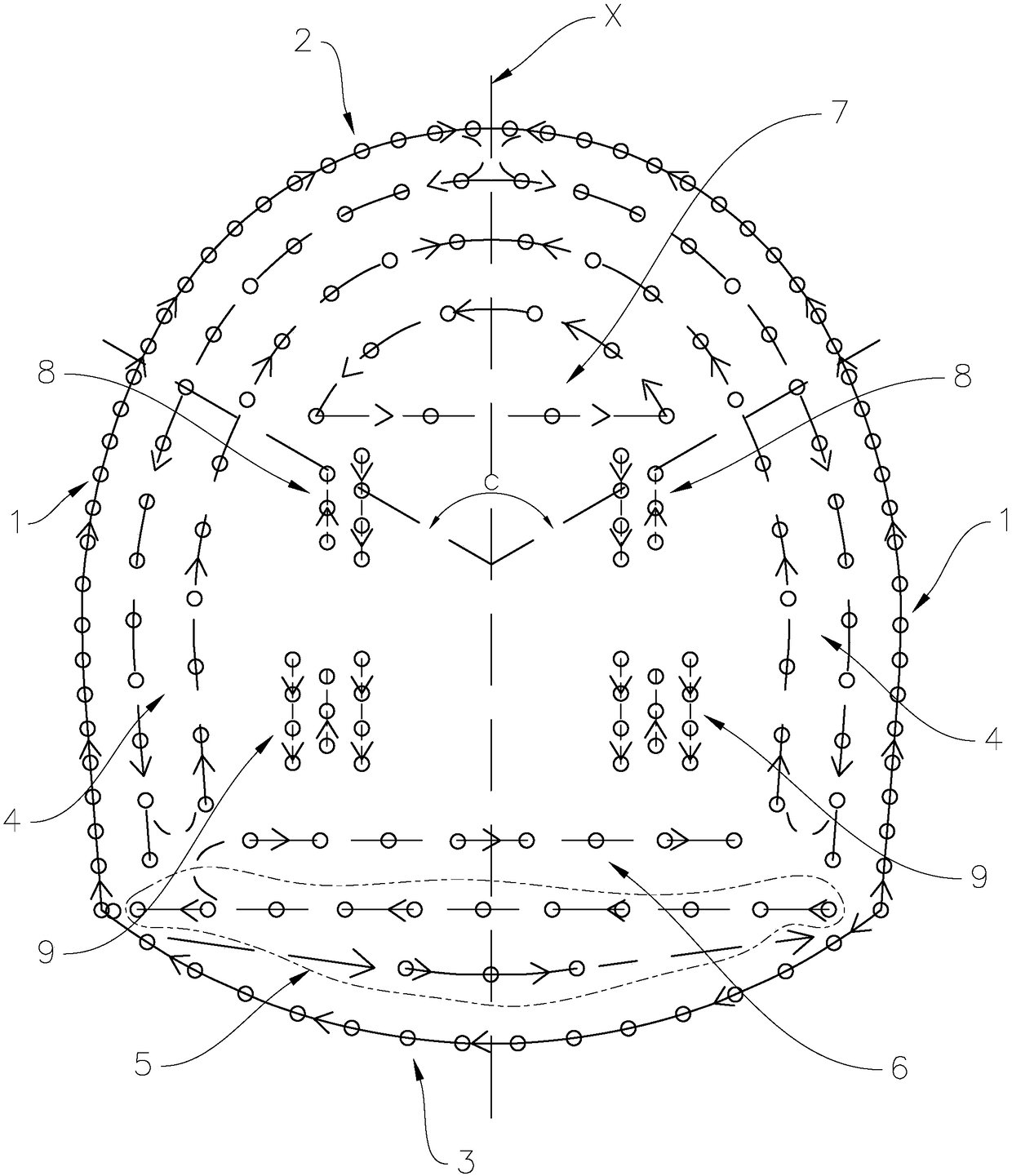

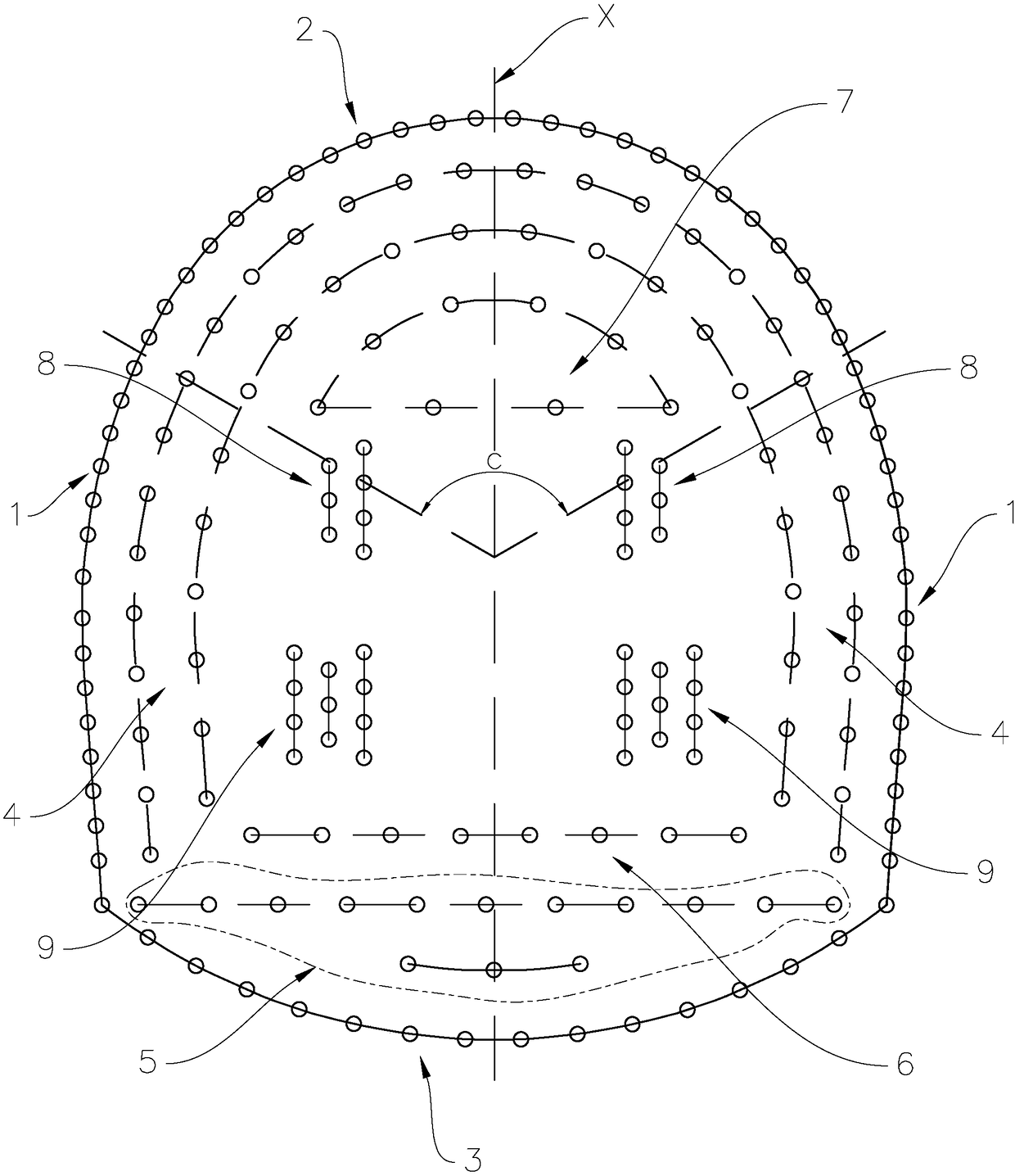

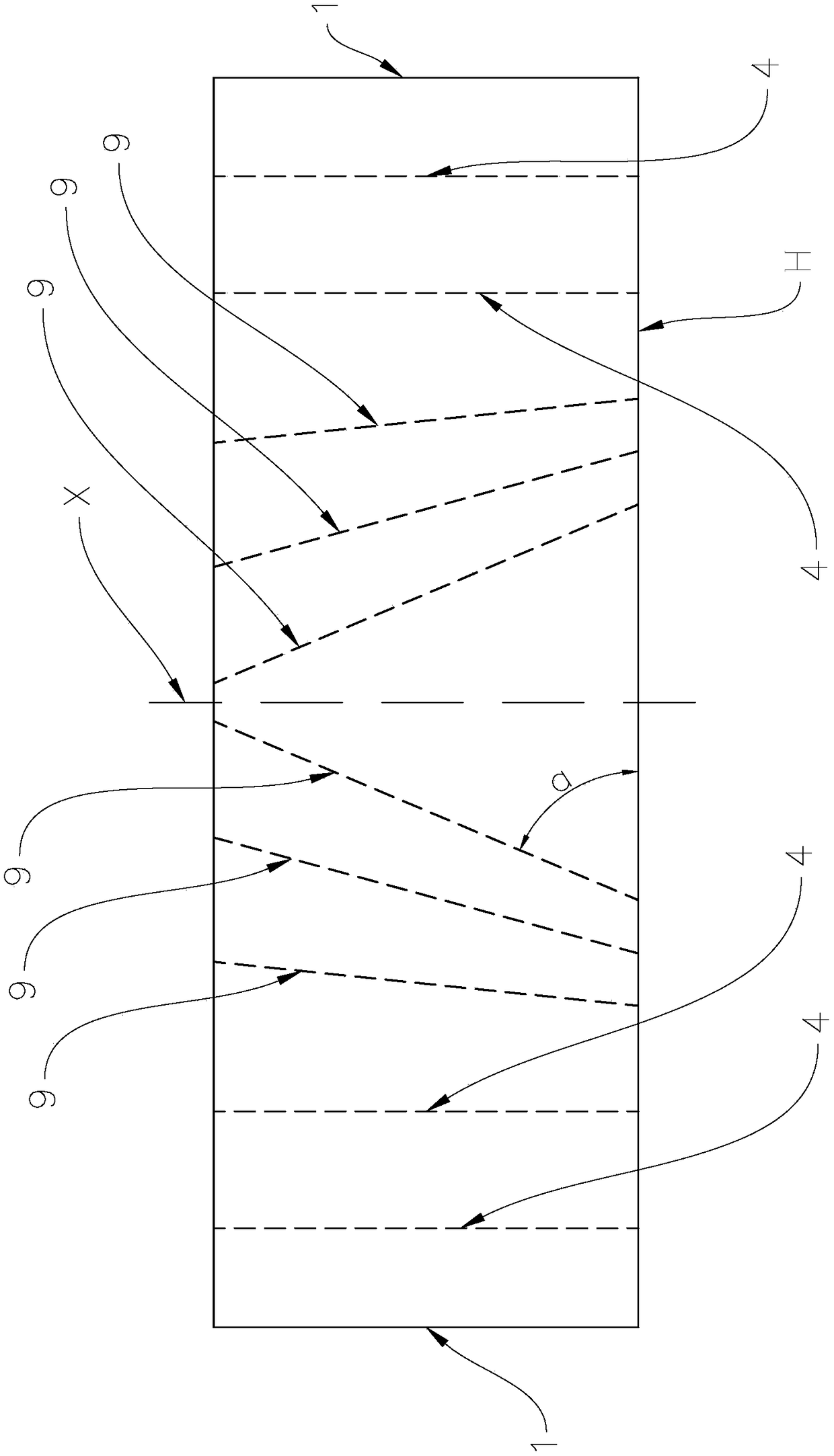

[0027] The tunnel hole layout blasting method provided by the present invention is mainly used in the excavation and blasting of tunnels. It can realize high-efficiency blasting of the overall broken surrounding rock of the tunnel, and ensure that the over- and under-excavation of the needle contour line after blasting is controlled within 5 cm, and the blasting process It has the advantages of little disturbance to the surrounding rock around the tunnel contour line, and guarantees the construction cost, construction quality and construction safety of tunnel blasting. In addition, in the process of tunnel excavation, appropriate excavation methods should be selected according to the surrounding rock conditions of the mountain or the construction plan, such as the full-section method, three-step method, two-step method, etc., and should be used for different excavation methods. Combined with the surrounding rock of the tunnel, the structural layout of the drilling of the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com