Underground structure crack control construction method by adding inducing joints

A technology of underground structure and construction method, applied in underwater structures, infrastructure engineering, artificial islands, etc., can solve problems such as wall cracking, achieve easy operation, increase the scope of limiting cracking and deformation, and have good social and economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

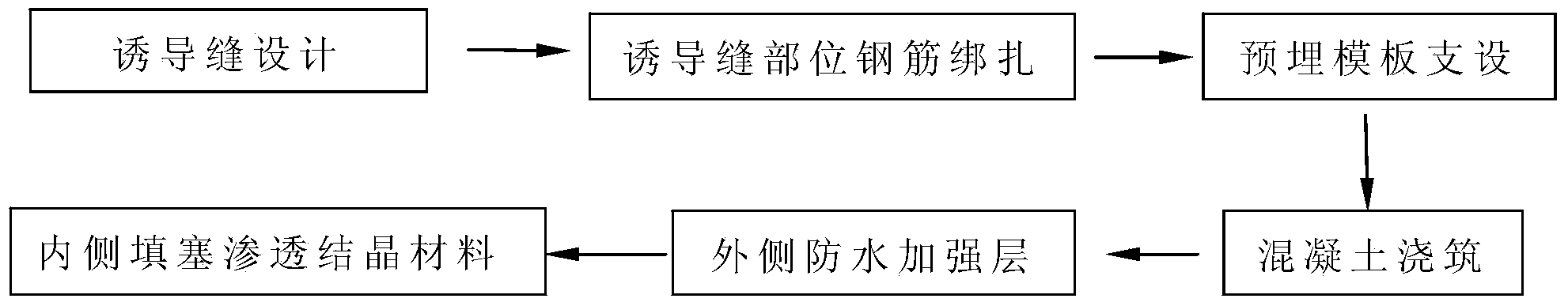

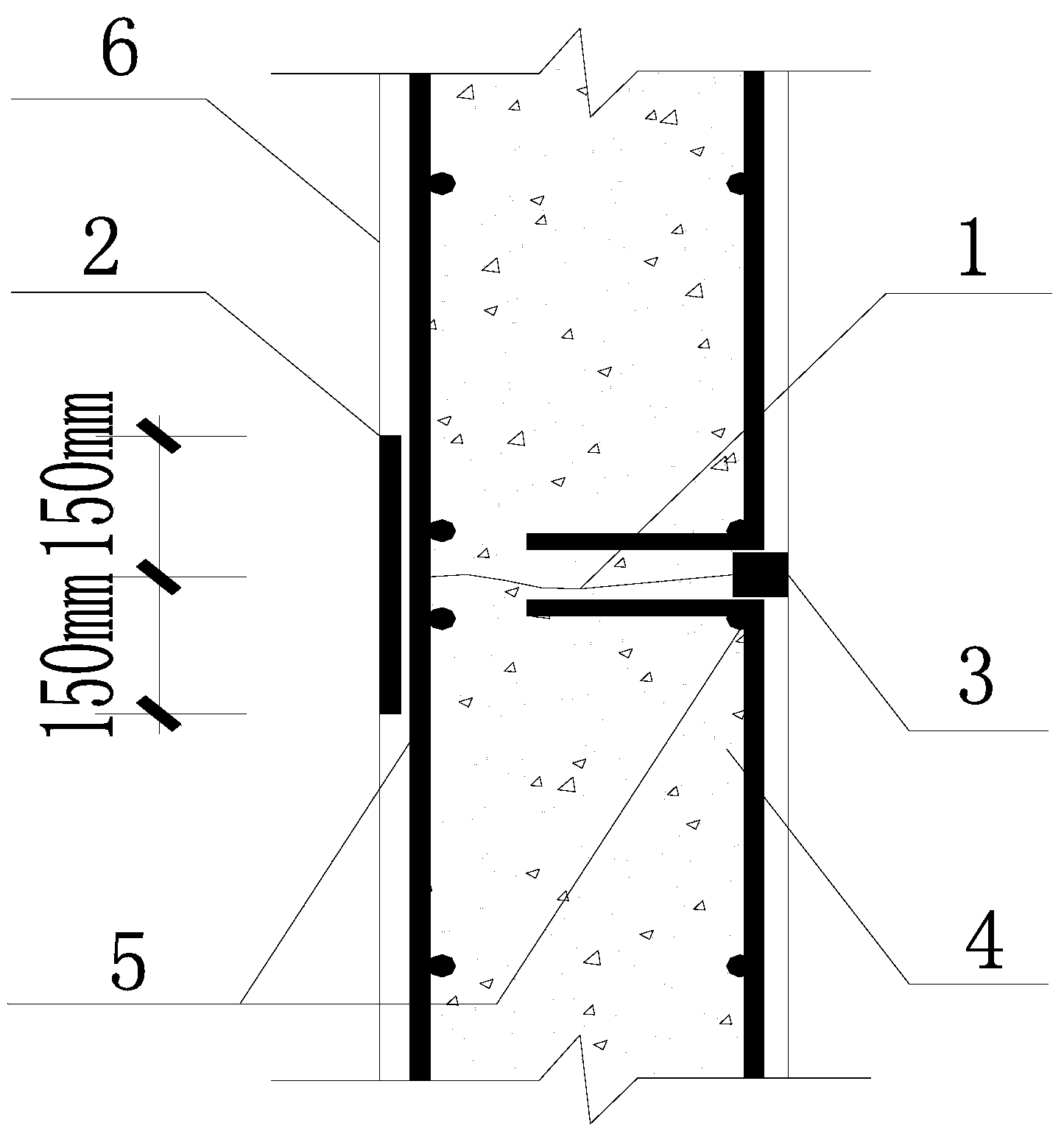

[0033] see figure 1 with figure 2 The anti-cracking construction method for adding induced joints to underground structures, including the design of induced joints, binding of steel bars at induced joints, pre-embedded formwork support, concrete pouring, external waterproof reinforcement layer and internal filling of permeable crystalline waterproof materials, the steps are as follows:

[0034] (1), induced seam design:

[0035] Through in-depth design, through the calculation and approval of the design institute, the position and spacing of the induced joints are determined. The width of the pre-cracked cracks after checking and calculation must meet the requirements of use. It is determined by the design and specification requirements that the induced joints cannot replace the expansion joints but can reduce the number of expansion joints ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com