Annular linear energy-accumulation cutter

A kind of energy-concentrating cutter and linear technology, applied in blasting and other directions, can solve problems such as unfavorable mining operations, achieve high utilization rate of explosives, reduce gas explosion and fire accidents, and eliminate danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

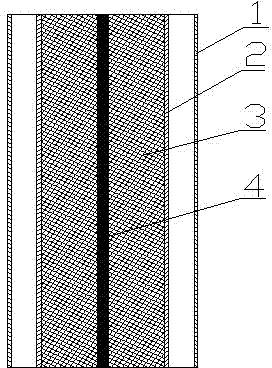

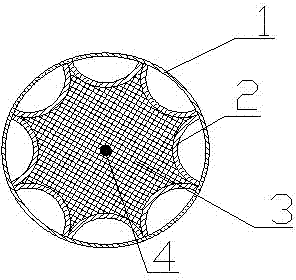

[0027] Example 1 Eight-directional semicircular circular linear energy-gathering cutter

[0028] see figure 1 with figure 2 , the constraining shell 1 is a plastic cylindrical tube with a thickness of Φ40mm, a wall thickness of 1mm, and a length of 75mm. Eight copper semicircular tubes 2 of the same length as the constraining shell are placed in turn on the inner periphery of the shell. The diameter of each copper semicircular tube is Φ16mm. The wall thickness is 1mm. The middle of the 8 copper semicircular tubes is ammonium nitrate explosive 3, and its charge density is 1.6g / cm 3 -1.7g / cm 3 within range. The detonating tube 4 is installed in the middle of the ammonium nitrate explosive, and the axis of the detonating cord coincides with the axis of the constraint shell.

[0029] The eight-way semicircular tube linear energy-gathering cutter of the present embodiment is used to cut 45# steel ingot test: a deep hole with a diameter of 60mm is processed on the 45# steel in...

Embodiment 2

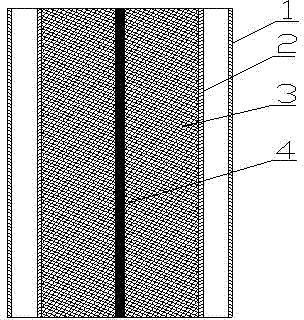

[0030] Example 2 Ten-directional semicircular circular linear energy-gathering cutter

[0031] see image 3 with Figure 4 , the constraint shell 1 is a Φ50mm, 1mm thick, and 75mm long plastic cylindrical tube, and 10 plastic circular tubes of Φ16mm, 0.6mm thick, and equal in length to the constraint shell are placed on the inner periphery of the shell. Ammonium oil explosive 3 is used as the main charge. The detonator 4 is installed in the middle of the ammonium oil explosive, and the axis of the detonator coincides with the axis of the constraint shell, and can be directly detonated with a detonating cord.

[0032] Cut the 45# steel ingot test on the ten-way semicircular tube linear energy-gathering cutter of the present embodiment: process a deep hole with a diameter of 60mm on the 45# steel ingot, place the above-mentioned energy-gathering cutter in the middle of the hole and detonate, the result is 10 linear holes with a depth of 13 mm and a diameter of 7 mm are evenly...

Embodiment 3

[0033] Example 3 Eight-direction circular circular linear energy-gathering cutter

[0034] see Figure 5 with Image 6 , the constraining shell 1 is a plastic cylindrical tube of Φ60mm, 0.7mm thick, and 70mm long, and eight copper circular tubes 2 of Φ16mm, 1mm thick, and equal in length to the constraining shell are placed in turn on the inner periphery of the shell. Emulsion explosive 3 is used as the main charge. The detonating tube 4 is installed in the middle of the emulsion explosive, and the axis of the detonating tube coincides with the axis of the constraint shell, and the detonating cord 4 can be directly detonated.

[0035] Carry out cutting 45# steel ingot test to the eight-direction circular circular linear energy-concentrating cutter of present embodiment: process the deep hole that diameter is 70mm on 45# steel ingot, place above-mentioned this energy-concentrating cutter in the middle of this hole and detonate, The result is that 8 linear holes with a depth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com