Blasting method for benches in open mining area

A technology for bench blasting and bench blasting, which is applied to the field of bench blasting in open-pit stopes, can solve problems such as poor stability, high construction cost, and increased construction difficulty, and achieve the effects of simple construction, reduced rock stripping, and optimal blasting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

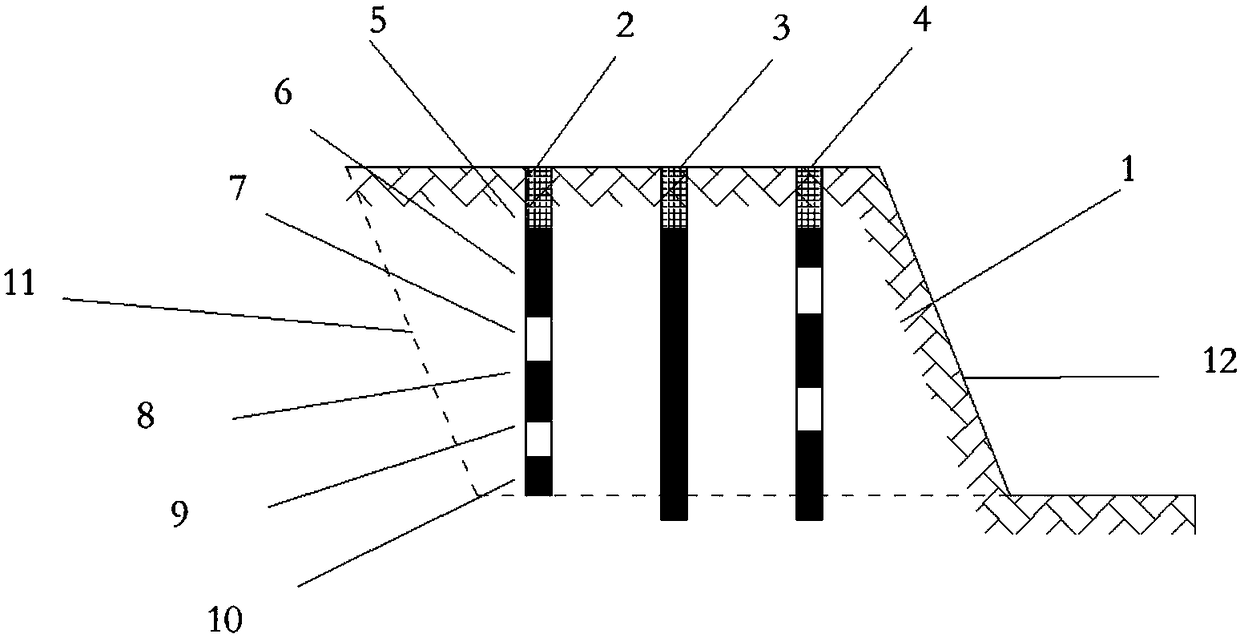

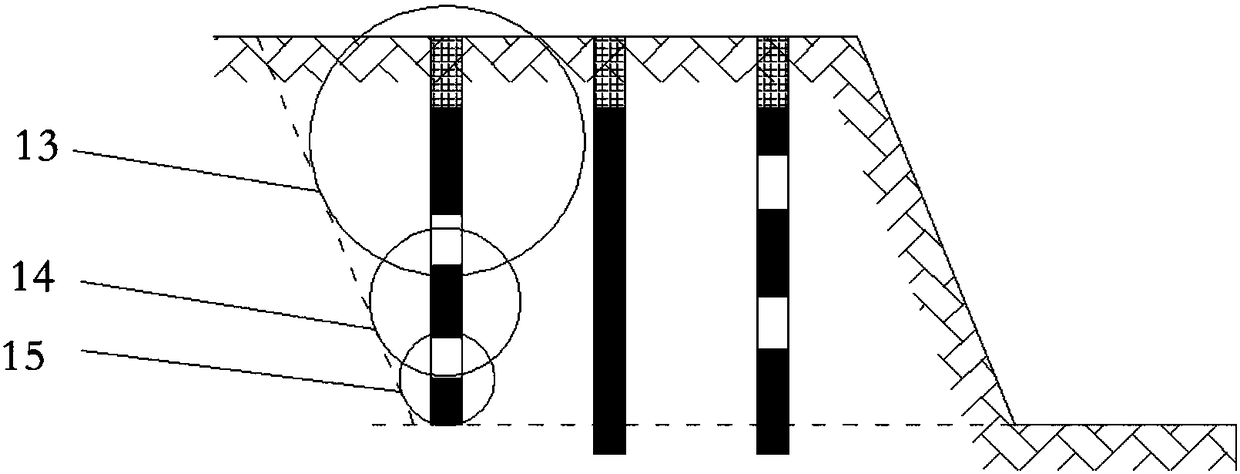

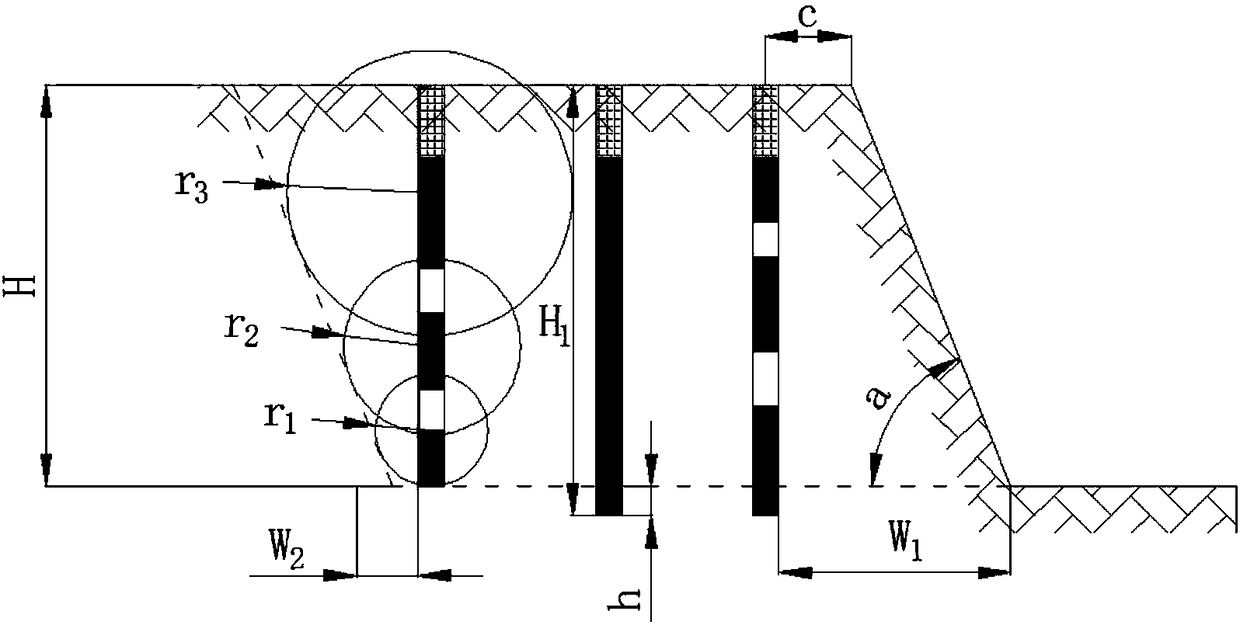

[0068] The method is further illustrated below in conjunction with the accompanying drawings.

[0069] The invention relates to a step blasting method in an open-pit stope. The method is based on a simple construction method, reduces the amount of rock peeling after blasting, and designs a reasonable hole layout method, charge method and blasting time. First, through the step height H and step slope angle α determined on the construction site, the required hole spacing a, row spacing b, single hole charge Q, and the depth H of the main blast hole 3 and blast hole 4 are determined. 1 , the blasting parameters of the differential blasting interval Δt; at least three groups of vertical holes are drilled vertically downward on the flat plate of the step 1, which are the pre-splitting holes 2 on the side of the pre-splitting surface of the step and the main blasting holes between the two rows 3. For the blast holes 4 on one side of the step slope, if the step width is too large, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com