Method for Determining Blast Stack Width in Step Blasting in Open Pit Mine

A technology of step blasting and determination method, which is applied in blasting and other directions, can solve problems such as difficulty in predicting the width of blast piles, and achieve the effects of improving shovel loading efficiency, reducing rock stripping, and reducing mining costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

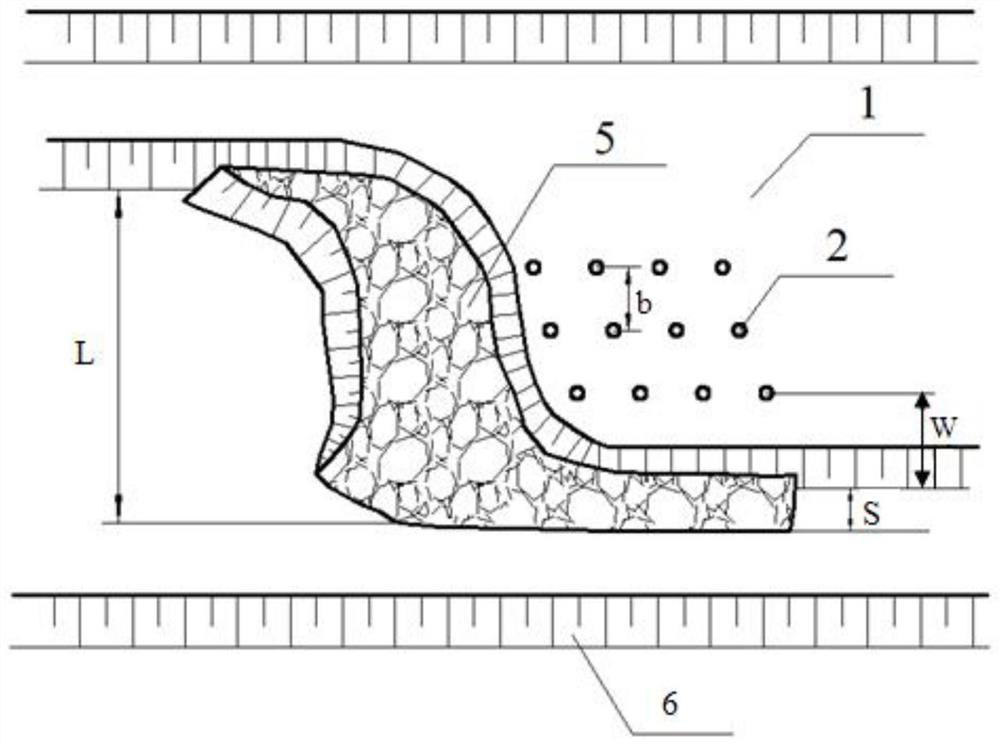

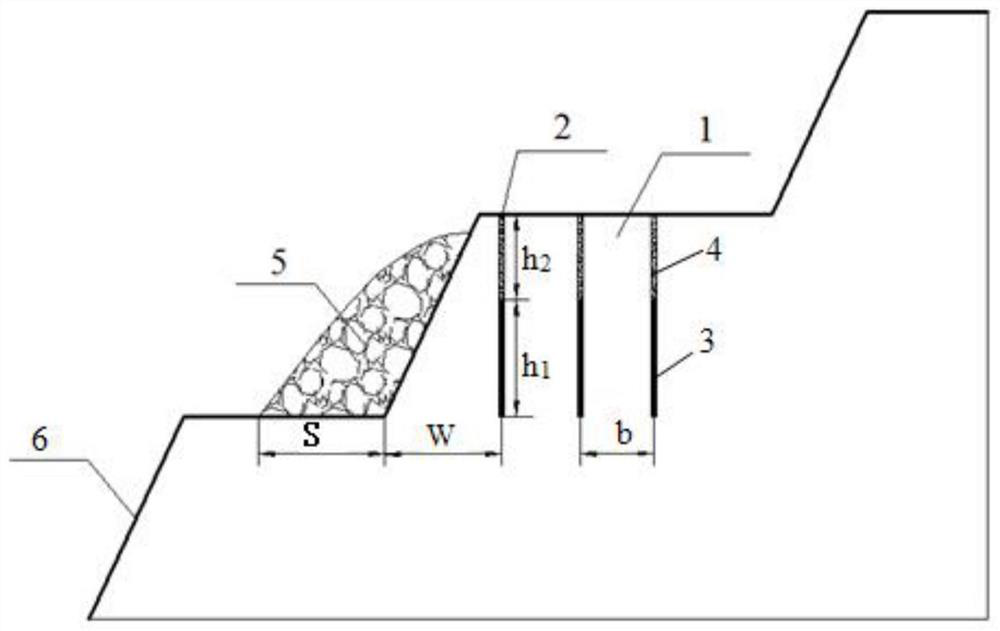

[0043] Implementation case: A large-scale open-pit iron mine with an annual output of 5 million tons, the diameter of the blast hole is 250mm, and powdery emulsion explosive is used; the hole distance during ballast blasting is 6.5m~7m, and the row distance b=5.6m~6m; ballast blasting holes The distance is 6m~6.5m, the row distance b=5.2m~5.6m; the width W of the chassis resistance line is 8m~8.5m, and the extra depth is 2m. The detonation scheme adopts slash detonation, and the number of rows of blastholes for each blasting is N=2 to 4 rows.

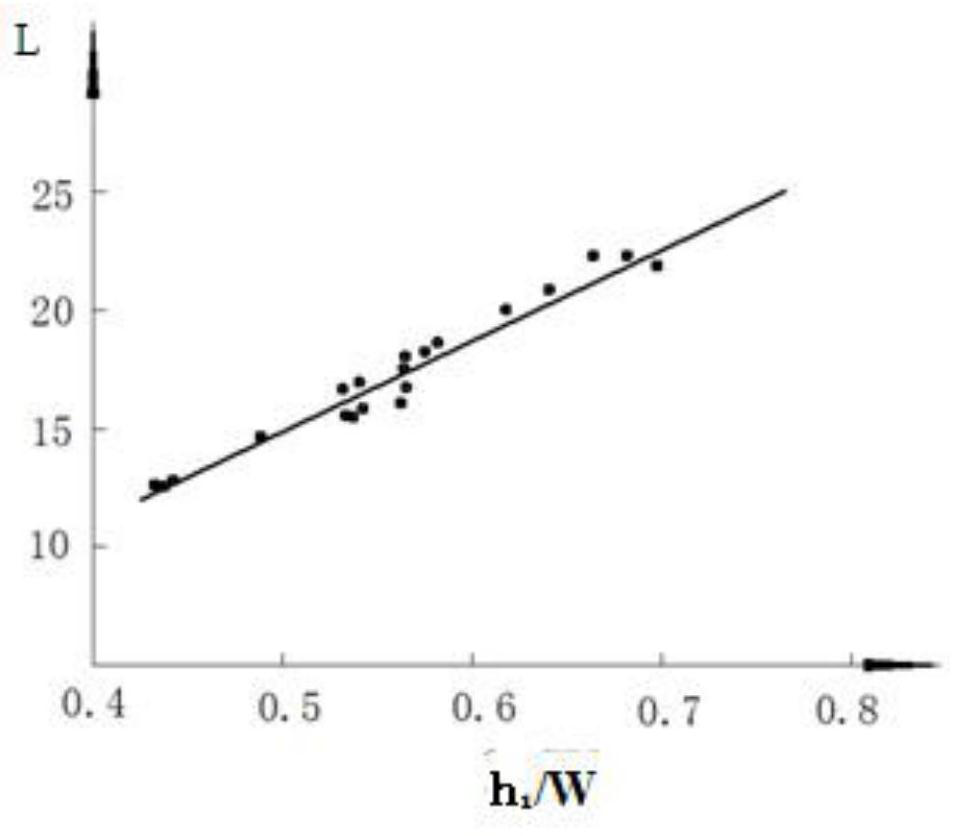

[0044] 1) When clearing ballast, h 1 The ratio of / W is controlled at 0.45~0.71. After a large number of field tests, the blast pile width L and h 1 / W relational equation, L=-5.2268+39.199·(h 1 / W), such as image 3 The blast pile width L and h of single-row hole blasting shown in the ballasting 1 / W diagram.

[0045] When multiple rows of holes are blasted, the blast pile width L=-5.2268+39.199·(h 1 / W)+(N-1)×5.8.

[0046] Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com