A method to optimize and control the blast pile width of bench blasting in open-pit mines

An optimized control and step blasting technology, applied in blasting and other directions, can solve problems such as difficulty in predicting blasting heap width and shovel-loading coordination and optimization, and achieve the effects of ensuring the safety of slope mining, reducing the amount of drop and improving the efficiency of shovel-loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

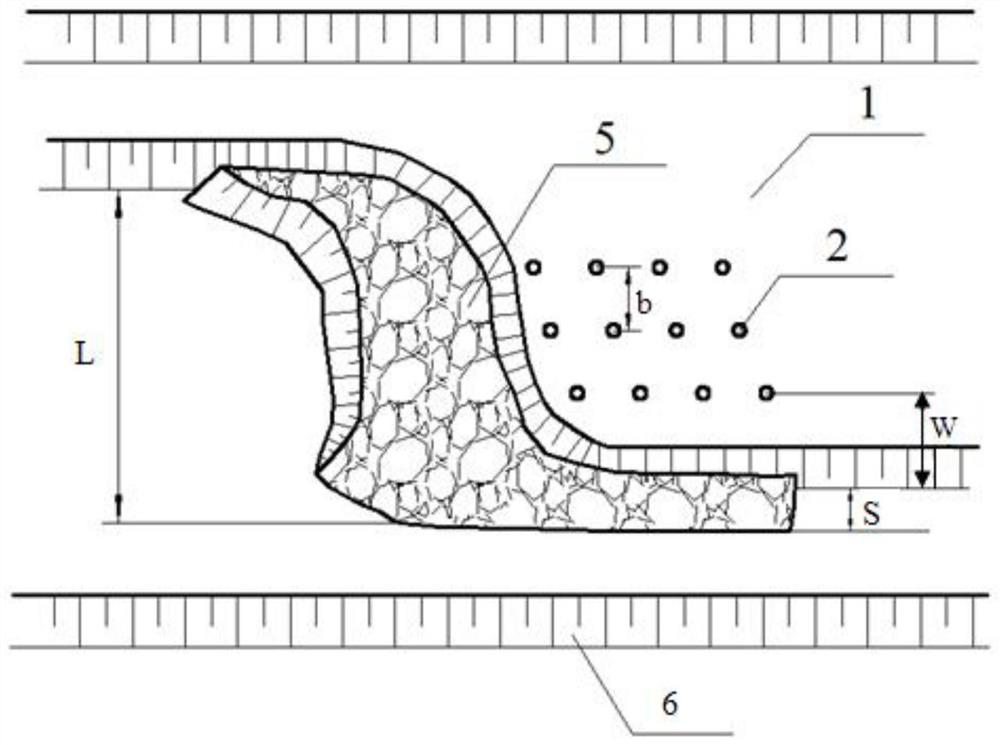

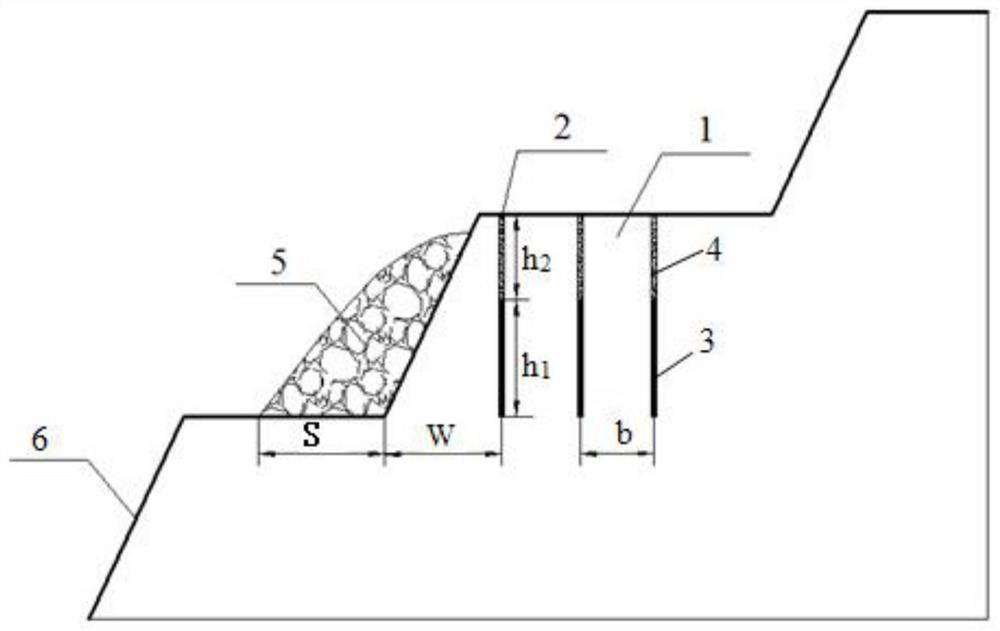

[0048] Implementation case: A large-scale open-pit iron mine with an annual output of 5 million tons, the diameter of the blast hole is 250mm, and powdery emulsion explosive is used; the hole distance during ballast blasting is 6.5m~7m, and the row distance b=5.6m~6m; ballast blasting holes The distance is 6m~6.5m, the row distance b=5.2m~5.6m; the width W of the chassis resistance line is 8m~8.5m, and the extra depth is 2m. The detonation scheme adopts slash detonation, and the number of rows of blastholes for each blasting is N=2 to 4 rows.

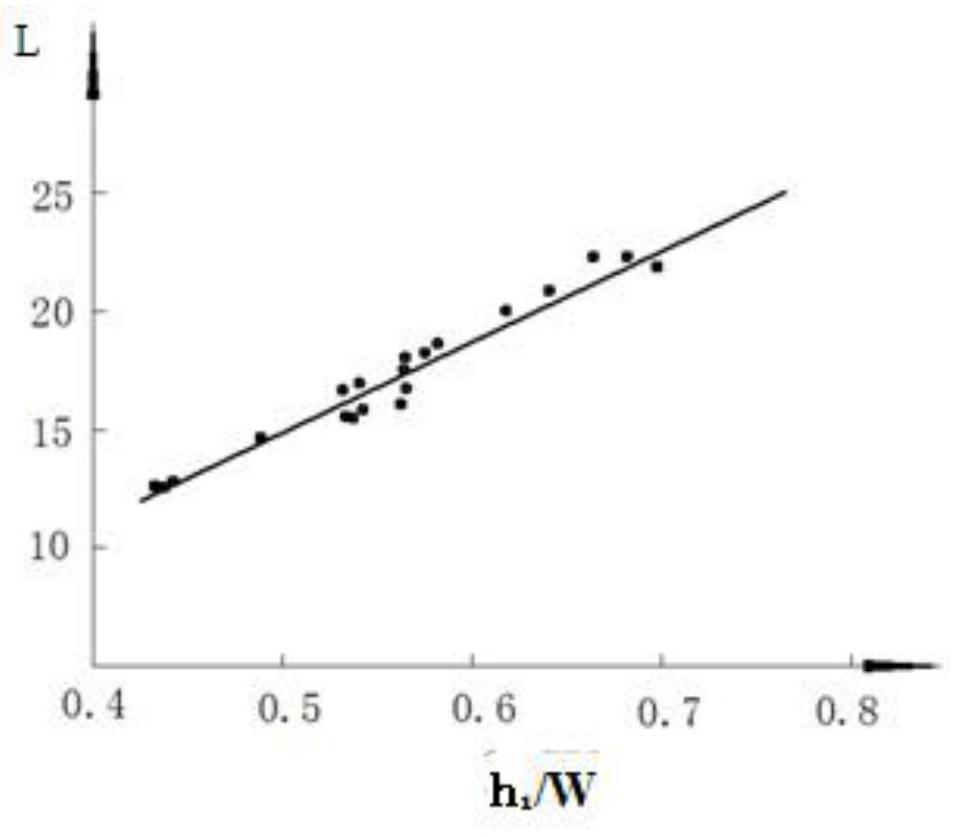

[0049] 1) When clearing ballast, h 1 The ratio of / W is controlled at 0.45~0.71. After a large number of field tests, the blast pile width L and h 1 / W relational equation, L=-5.2268+39.199·(h 1 / W), such as image 3 The blast pile width L and h of single-row hole blasting shown in the ballasting 1 / W diagram.

[0050] When multiple rows of holes are blasted, the blast pile width L=-5.2268+39.199·(h 1 / W)+(N-1)×5.8.

[0051] Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com