Mining method of surface mine

A mining method and mine technology, applied in surface mining, underground mining, special mining, etc., can solve the problems of unfavorable resource quality collocation and utilization, difficult control of step flatness, frequent movement of shovel equipment, etc., so as to reduce the generation of blasting foundation. , Improve the utilization rate of resource recovery and overcome the effect of blasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

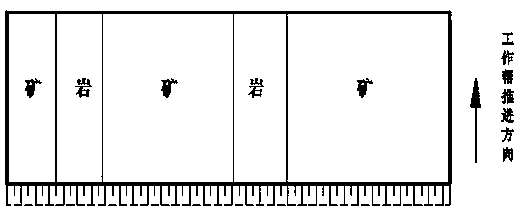

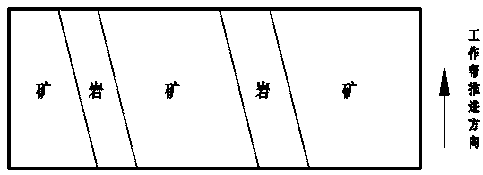

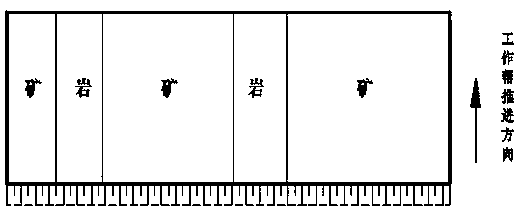

[0023] see Figure 1-2 , a mining method in an open-pit mine, carried out in the following steps:

[0024] Arrange blasting holes along the rock formation along the advancing direction of the working gang in the stope, and fill the holes with various explosives;

[0025] The location of the blasting hole is selected on both sides of the ore-rock boundary line to avoid mixed ore. The method adopts large-scale blasting operations to reduce the occurrence of side and corner holes and effectively reduce the occurrence of blasting roots;

[0026] The ore body and the rock are blasted at the same time, and the detonation is selected at the boundary line to ensure the separation of the ore and rock;

[0027] The vertical working gang advances and mines at the same time. According to the lithology shown in the longitudinal section diagram of the explosive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com