Method for preventing and treating impact mine pressure through high-dipping super-high-seam mining roadway combined pressure relief

A technology for mining tunnels and extra-thick coal seams, used in special mining, mining equipment, surface mining, etc., can solve the problem of not being able to economically and effectively reduce the degree of stress concentration in the coal seam and roof and floor, restricting the safe and efficient mining of steeply inclined coal seams, and inconsistency in parameters. Reasonable and other issues, to reduce the risk of rock burst dynamic disaster, avoid rock burst dynamic disaster, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below.

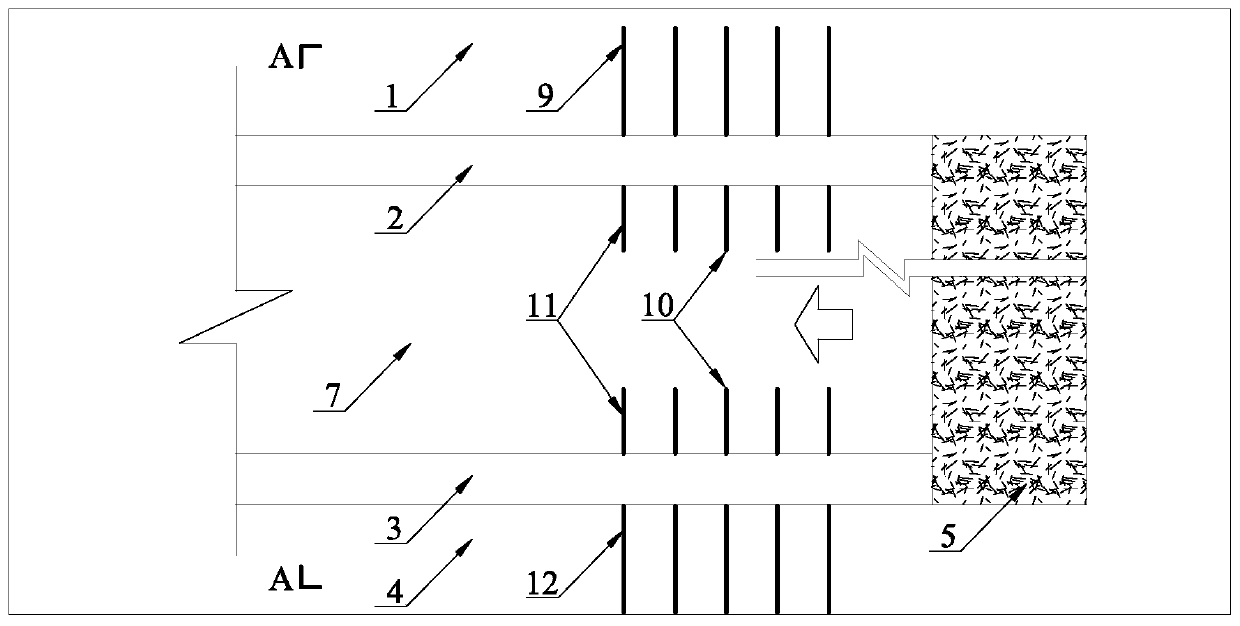

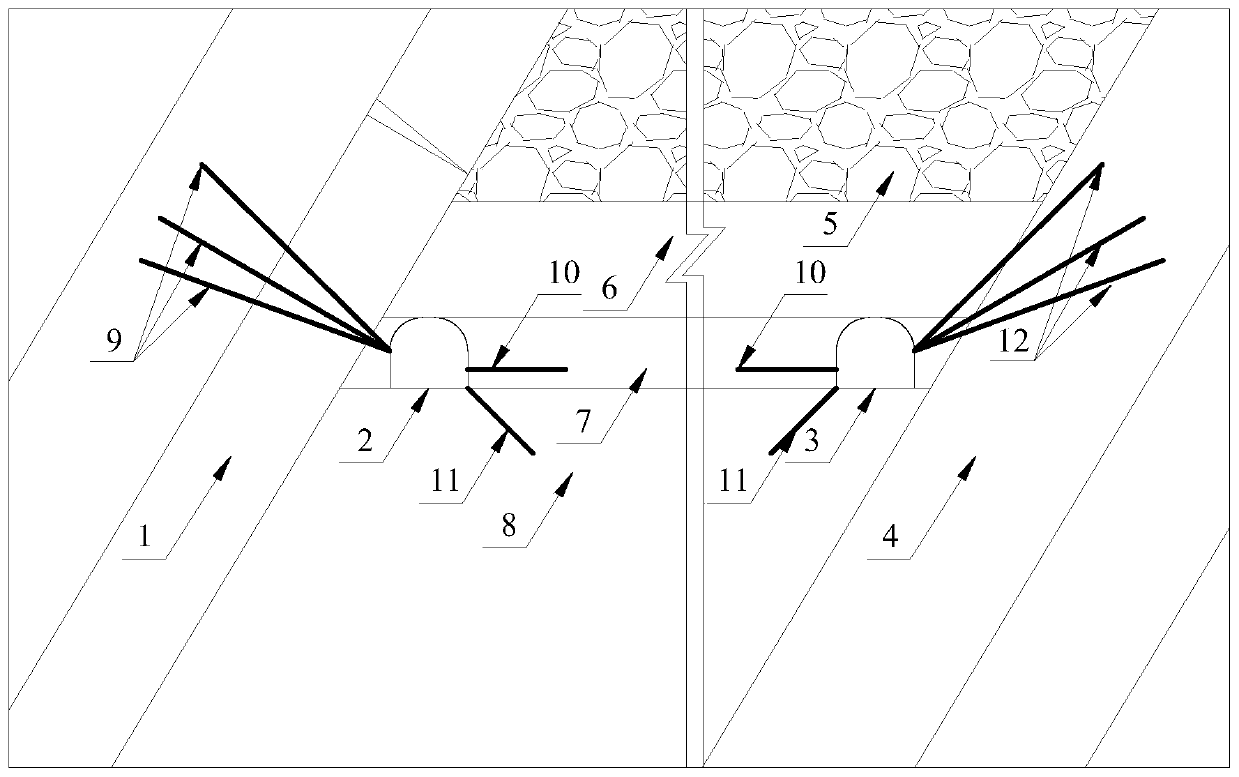

[0018] As shown in the figure, the concrete steps of the present invention are:

[0019] A. Determine the coal blasting and pressure relief arrangement at the side of the roadway: start from the two sides of the mining roadway 30m in front of the working face, and drill the blasting pressure relief borehole I10 at the side of the coal body 7 side of the working face, And arrange multiple blasting pressure relief drilling holes I10 in a single row forward along the side, and the distance between the blasting pressure relief drilling hole I10 farthest from the working face and the working face is not less than 150m; each blasting pressure relief drilling hole I10 is perpendicular to the mining roadway and has an angle of 3° to 5° with the horizontal direction of the coal body. Multiple explosive tubes are installed in each blasting pressure relief borehole I10, and the explosives in each blasting pressure relief bor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com