Method for pre-cracking and softening of igneous rock hard roof

A technology for hard roof and igneous rock, which is applied in the field of high-pressure acid solution injection to crack and soften the hard roof of igneous rock, drilling in advance, pre-cracking and softening the hard roof of igneous rock, and can solve potential safety hazards, high equipment requirements, and the impact of coal seam mining efficiency, etc. problems, to achieve the effect of reduced construction difficulty and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

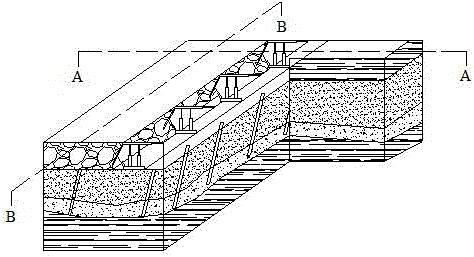

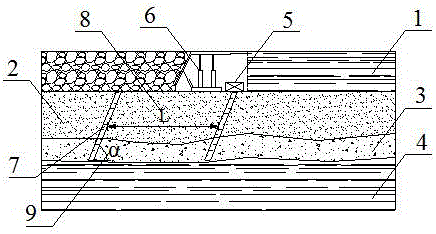

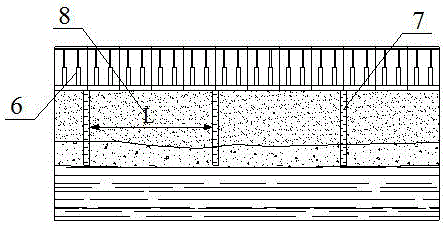

[0048] Taking the Carboniferous Permian coal seam of Datong Coal Mine as an example, the distribution of its mineable coal seams is shown in Table 1, and the stratum histogram of Tashan Coal Mine is shown in Figure 5 shown.

[0049] Table 1 Distribution of recoverable coal seams in Carboniferous Permian in Datong mining area

[0050]

[0051] Combine Table 1 with Figure 5 It can be known that the Carboniferous Permian recoverable coal seam in Tashan mine is mountain 4 The No. 3-5 coal seam and No. 2 coal seam were seriously invaded by igneous rock (lamprophyre), and most of them were unminable. The top of No. 3-5 ultra-thick coal seam was invaded by layered lamprophyre, and the thickness of the intrusion was as thick as 6m. Mountain 4 No. coal seam can be mined partly by lamprophyre intrusion. where the mountain 4 The average distance between No. 3 and No. 5 extra-thick coal seams is 26m.

[0052] In view of the problem of layered igneous rock hard roof in the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com