Semi-rigid base layer anti-cracking pavement structure and construction method suitable for high-temperature-difference area

A technology of semi-rigid base and pavement structure, which is applied to cohesive pavement paved on site, roads, roads and other directions, which can solve problems such as crack reflection and achieve the effect of ensuring overall performance, high crack regularity and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

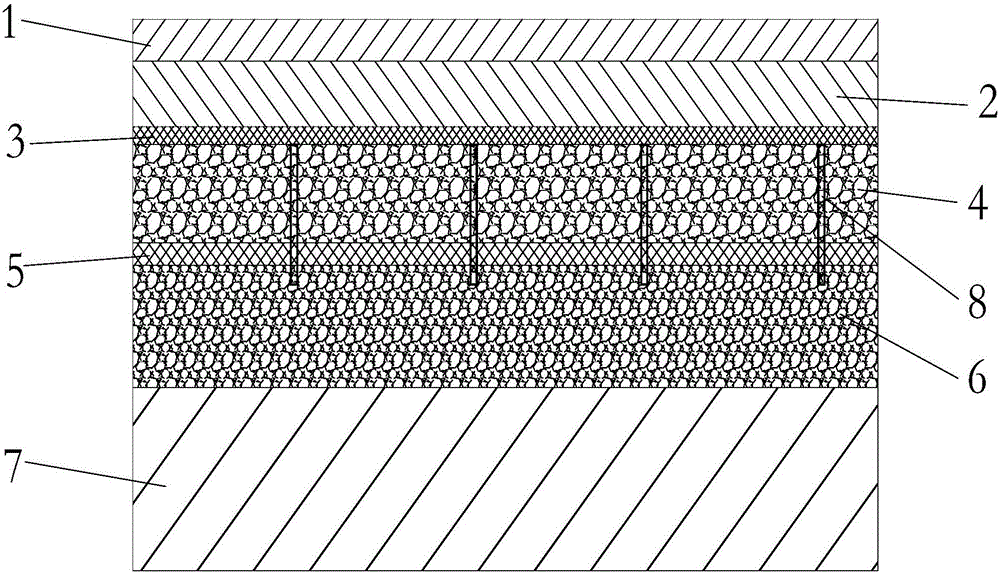

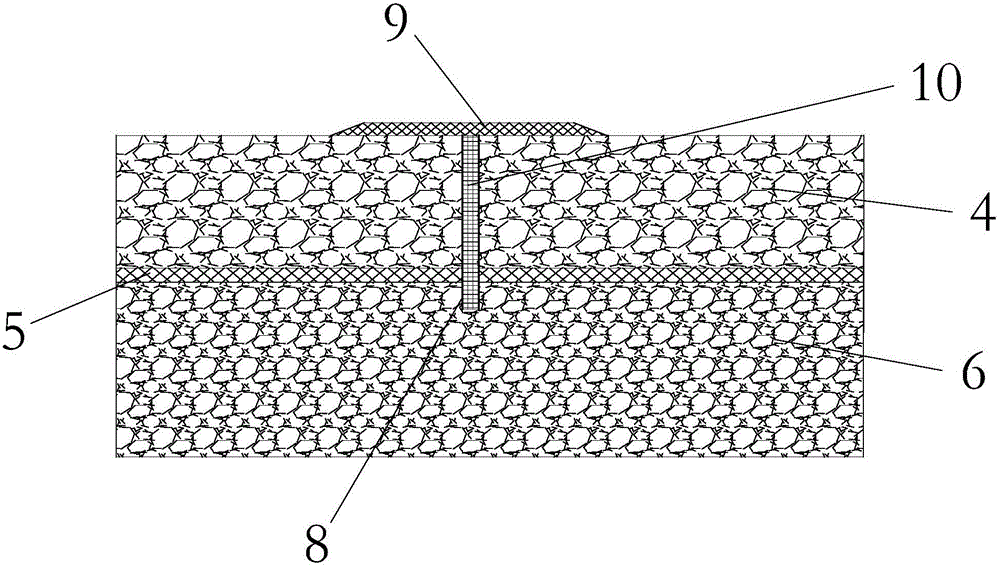

[0030] Such as Figure 1 ~ Figure 2 As shown, a semi-rigid base anti-cracking pavement structure suitable for areas with high temperature differences, including the surface layer, base layer and pre-cracks, the base layer and the surface layer are arranged in sequence from bottom to top, and the base layer includes the lower base layer 6 and The upper base layer 4 and the surface layer include the lower layer 2 and the upper layer 1 arranged in sequence from bottom to top, and the lower layer 2 is arranged on the upper base layer 4 . There are several pre-cracks in the base layer. After the construction of the upper base layer 4 is completed, pre-cut joints are made at the position of 300h ° C (h ° ° C is the product of the curing time h and the ambient temperature °C) of the base layer. The pre-cracks include pre-cut joints 8. The caulking material 10 and the joint material 9, the upper end of the pre-slit pre-slit 8 is flush with the upper surface of the upper base 4, the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com