Prevention method for pressure bump of approximately-vertical super-thick coal seams

A technology of rock burst and extra-thick coal seam, which is applied in ground mining, earthwork drilling, underground mining, etc., can solve the problems of high risk and achieve the effect of reducing risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

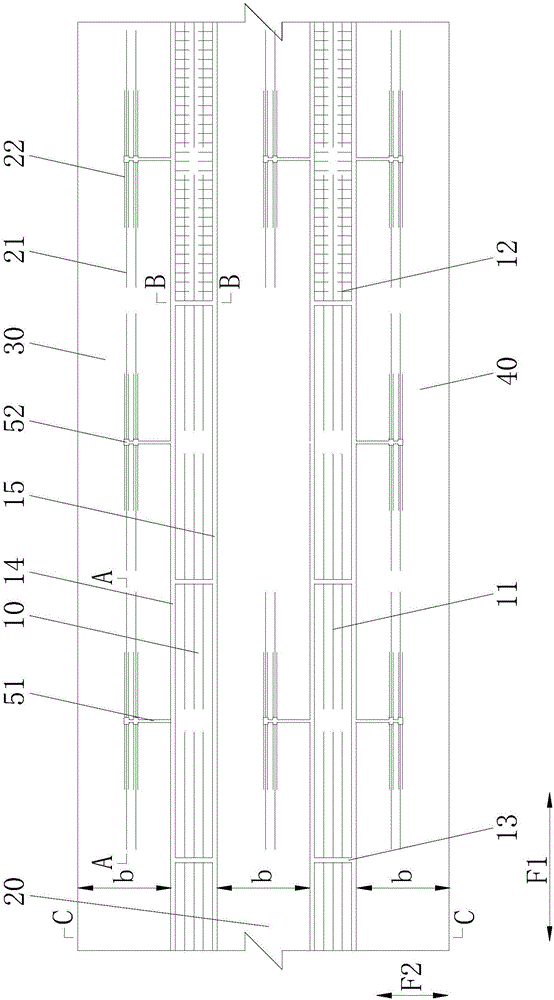

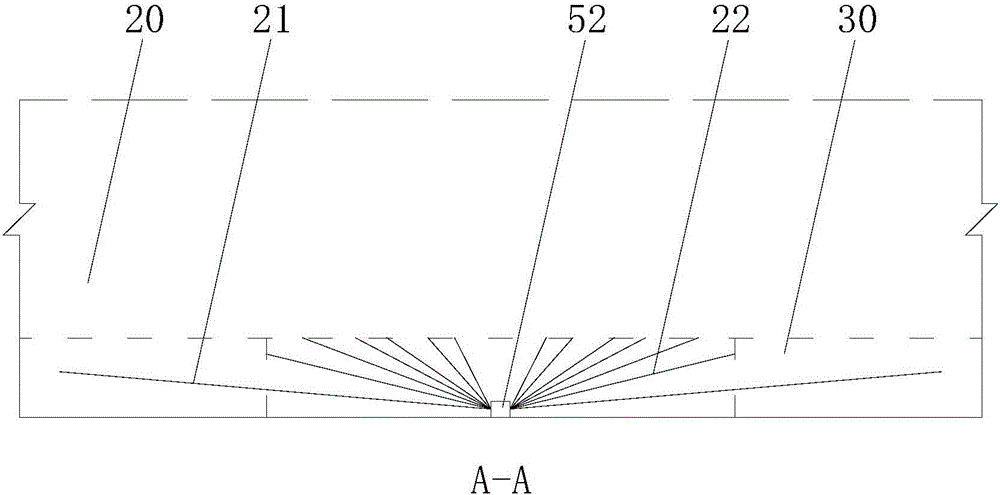

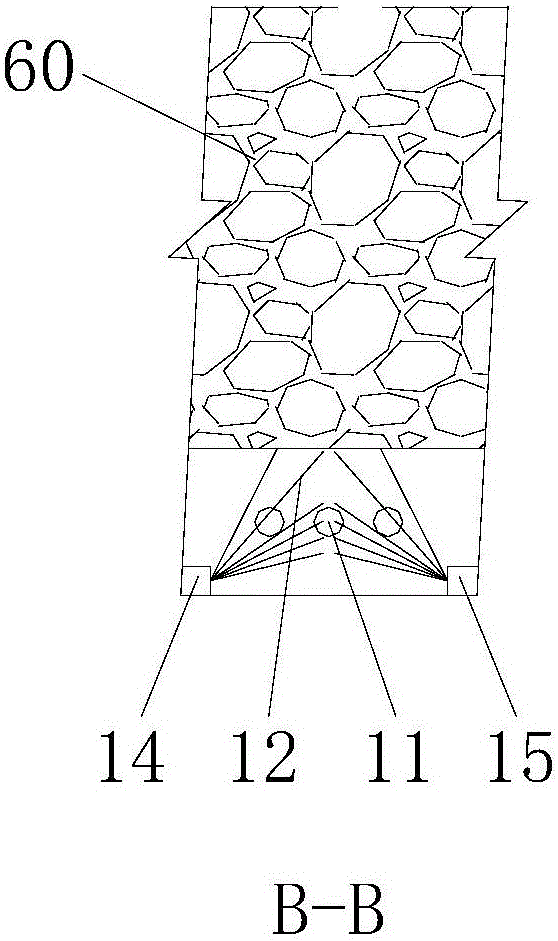

[0045] Such as Figure 1 to Figure 4 Shown is an embodiment of the method for preventing and controlling rock burst in a near-vertical extra-thick coal seam of the present invention. combine figure 1 As shown, the control method includes the following steps:

[0046] S1. Before the mining of the horizontal coal seam 10 at each stage, the rock pillar 20, the coal seam roof 30, and the coal seam floor 40 of the corresponding mining level are softened by water injection, so as to block the transfer of the regional structural horizontal stress to the rock mass, that is, to slow down the formation of rocks. The energy accumulation degree of column 20, coal seam roof 30 and coal seam floor 40;

[0047] S2. Carry out pre-splitting blasting to the rock pillar 20, the coal seam roof 30, and the coal seam floor 40 of the corresponding mining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com