Stope structure arrangement manner through fast-tilting extremely-thin vein cliff filling stoping method

A backfill mining method and structural arrangement technology, which is applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of large dilution loss rate, low rock drilling efficiency, poor surrounding rock deformation effect, etc., and achieve control of surrounding rock deformation. , the effect of reducing the ore dilution rate and increasing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

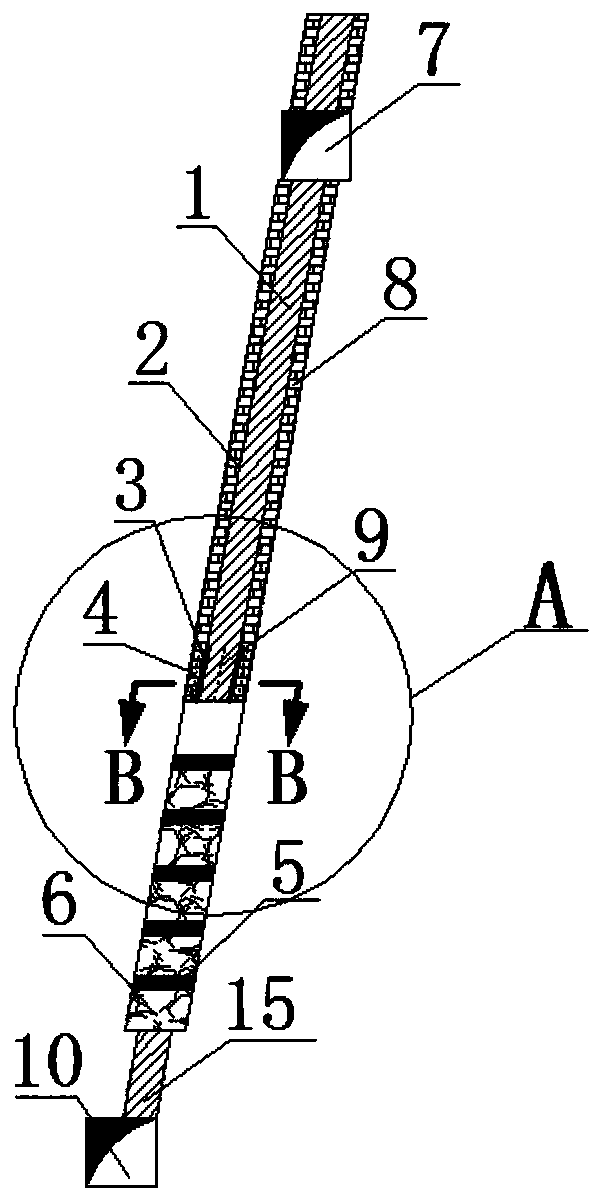

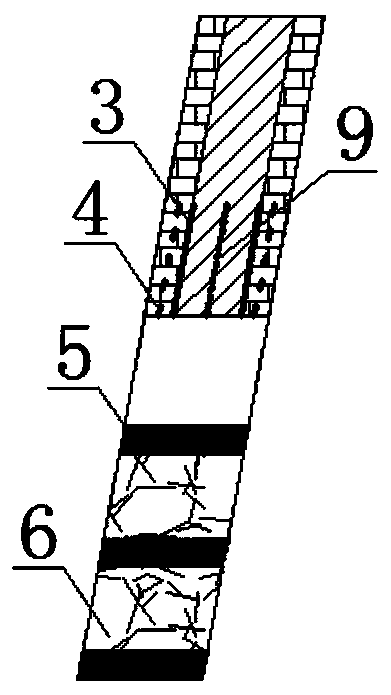

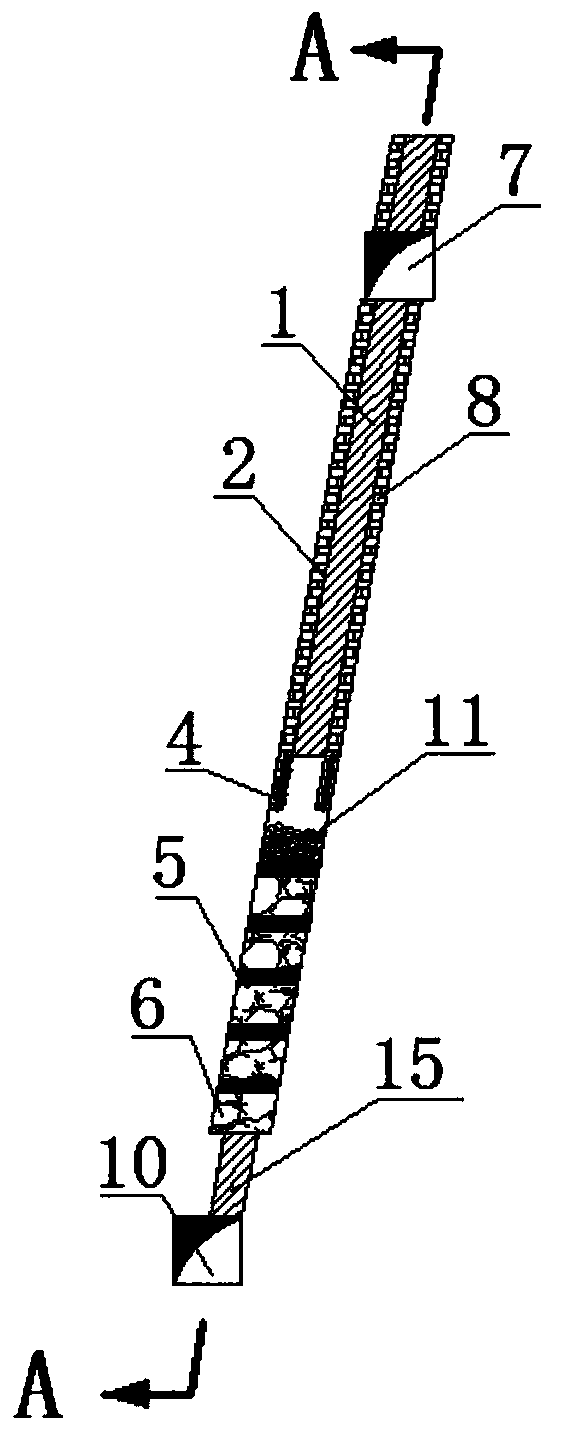

[0029] In order to better describe the present invention, a further detailed description of the stope structure layout of the steeply inclined extremely thin vein wall-cutting and filling mining method of the present invention will be given below in conjunction with the accompanying drawings. In the embodiment, the average thickness of the ore seam is 0.72 meters, and the inclination angle of the ore vein is 68.5°, which belongs to the extremely thin ore vein with steep slope.

[0030] Depend on figure 1 Shown is a schematic diagram of the stope structure layout of a steeply inclined extremely thin vein wall cutting and filling mining method of the present invention and combined with figure 2 , image 3 It can be seen that a kind of steeply inclined extremely thin vein wall-cutting and filling mining method stope structure arrangement method of the present invention, along the vertical direction of the ore vein, in the inside of the ore body, the middle section of the transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com