Method for manufacturing novel composite material through non-biomass substances in household refuse

A technology of domestic waste and composite materials, applied in the field of new composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

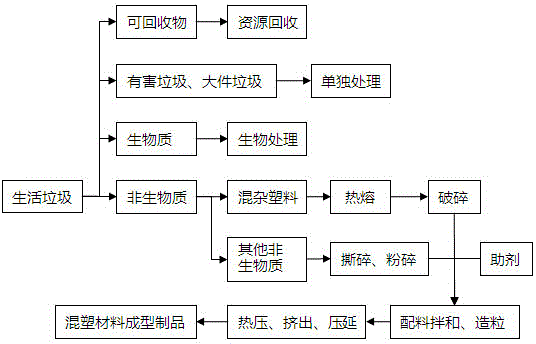

[0014] Please refer to the attached figure 1 .

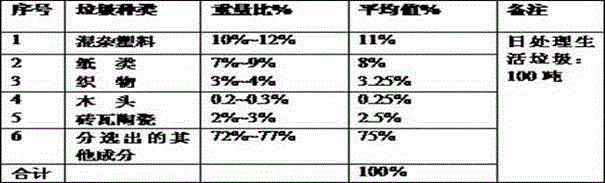

[0015] In a domestic waste comprehensive treatment plant in a certain place in Northwest my country, after sorting out recyclables, hazardous waste, bulky waste, and biomass in domestic waste and performing corresponding treatment, the remainder—the non- The composition of biomass is shown in the table below:

[0016]

[0017] Non-biological matter (items 1 to 5 in the table) in domestic waste accounts for about 25% of the total domestic waste, of which mixed plastics account for the largest proportion, accounting for 11%.

[0018] Sorting out mixed plastics (mainly including PE, PP, PS, PVC, ABS) without washing, directly heating and melting, the temperature is not higher than 200 ℃, forming a lump, after cooling, it is broken into particles smaller than 10mm Standby; at the same time, shred paper and fabric into flakes smaller than 20mm, crush wood into powder smaller than 2mm, and crush bricks and ceramics into particles ...

Embodiment 2

[0020] The domestic garbage used and the processing of mixed plastics, paper, fabrics, wood, brick and tile ceramics are the same as in Example 1.

[0021] Mix plastic particles and fillers at a ratio of 1:0.8 to 1.2, add additives (weight ratio ≤3%) to increase the compatibility between mixed plastics and the coupling between plastics, plant fibers and inorganic substances, and carry out mixing, Pelletization: Produce mixed plastic material profiles through twin-screw extrusion process to make building materials with high requirements on strength, shape and appearance, such as agricultural greenhouse skeletons, park seats, guardrails, and flower boxes. This type of mixed plastic material is suitable for absorbing all the fiber components (such as paper, fabric, wood) in the domestic garbage in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com