Axial force balance device used for performance testing of axial-flow gas compressor

A technology of axial flow compressor and balancing device, which is applied in the components of pumping device for elastic fluid, mechanical equipment, machine/engine, etc. Bearings are difficult to fully bear and other problems, so as to prolong the service life, improve the use efficiency, and save money.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by specific embodiment:

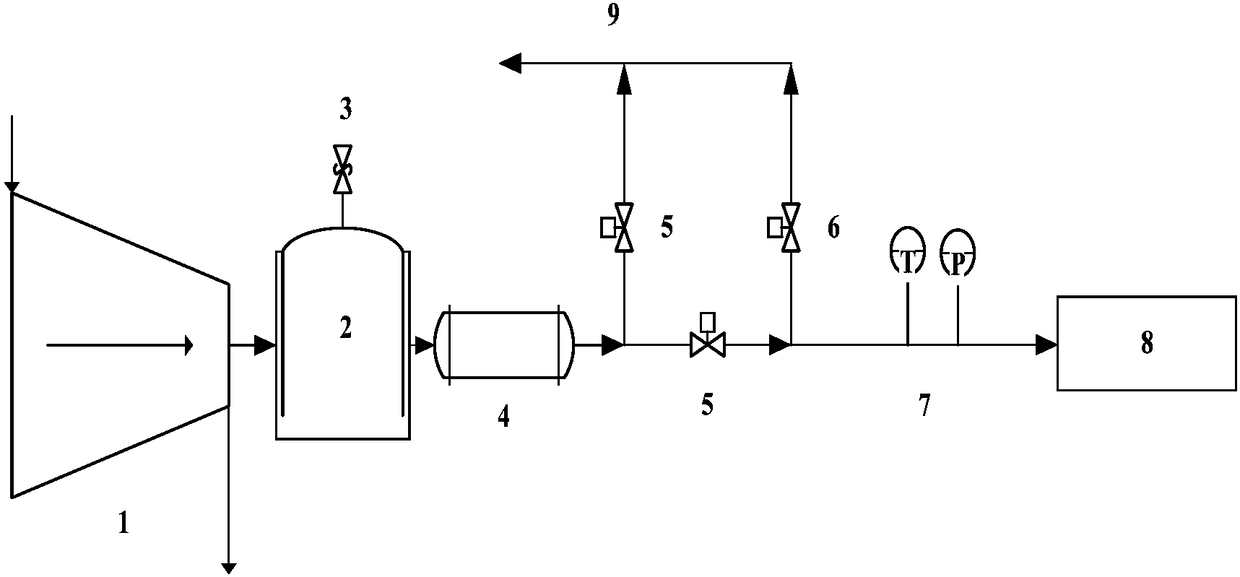

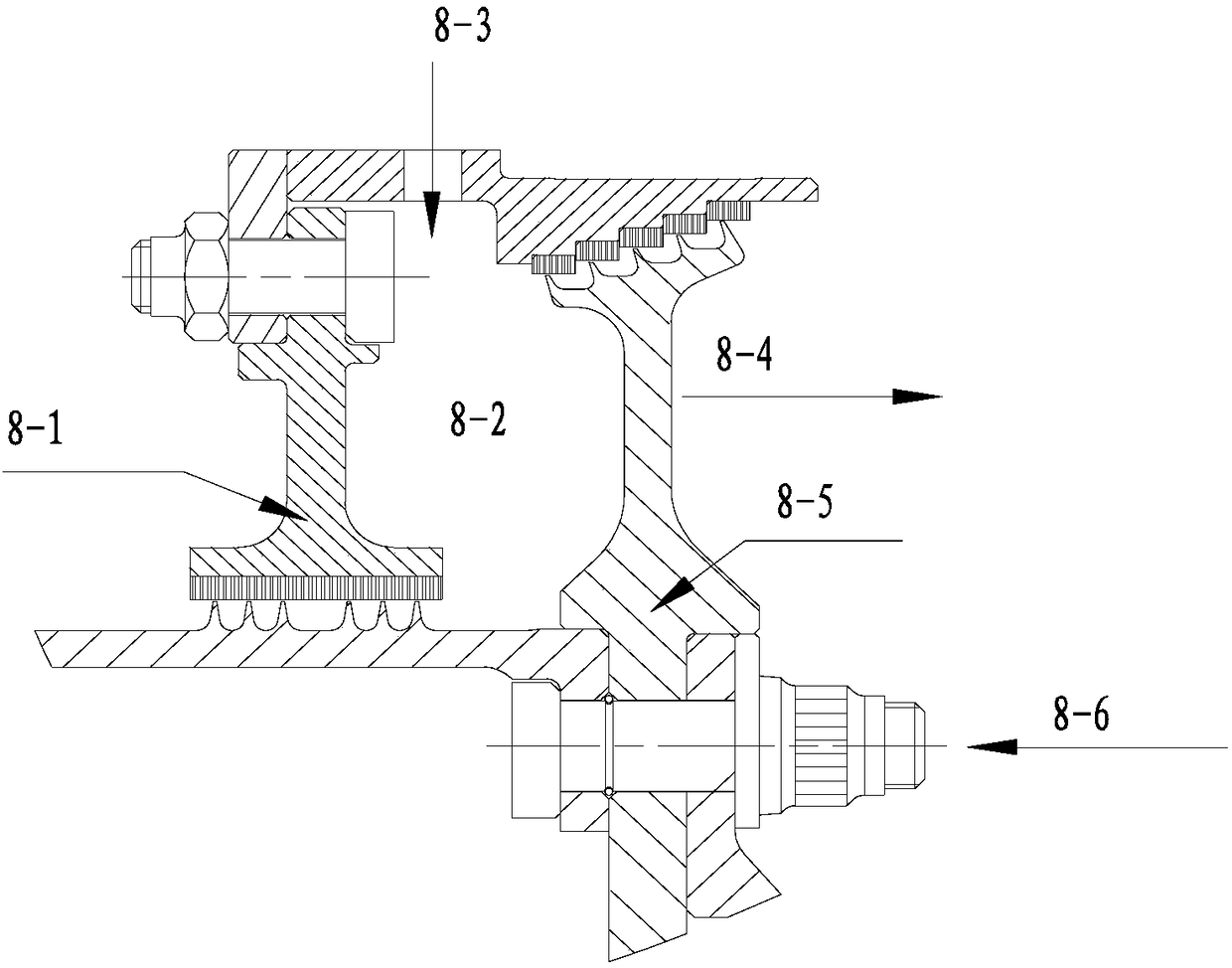

[0013] see figure 1 , the device is composed of a compressor 1, an air storage tank 2, a dryer 4, a pressure regulating valve 5, a solenoid valve 6, a test unit 7, a test piece balance chamber 8 and related pipelines, etc. The output of the compressor 1 has a certain pressure The gas enters the gas storage tank 2 for pressure maintenance and then passes through the dryer 4. After drying and water removal, two pressure regulating valves 5 and the venting pipeline 9 are used to adjust the gas supply pressure, and the test unit 7 is used to collect and supply the balance of the test piece. The gas parameters (pressure, temperature) of the cavity 8, the solenoid valve 6 is set between the pressure regulating valve 5 and the test unit 7, and the vent line 9 is connected in series to meet the needs of rapid release of pressure in the system. The axial force balance control device is des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com