Crawling type micro pipeline robot

A pipeline robot and tiny technology, applied in special pipes, pipe components, mechanical equipment, etc., can solve the problems of small traction, difficult to achieve precise control, complex control system, etc., to achieve stable action, protect the output shaft, prevent shaking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

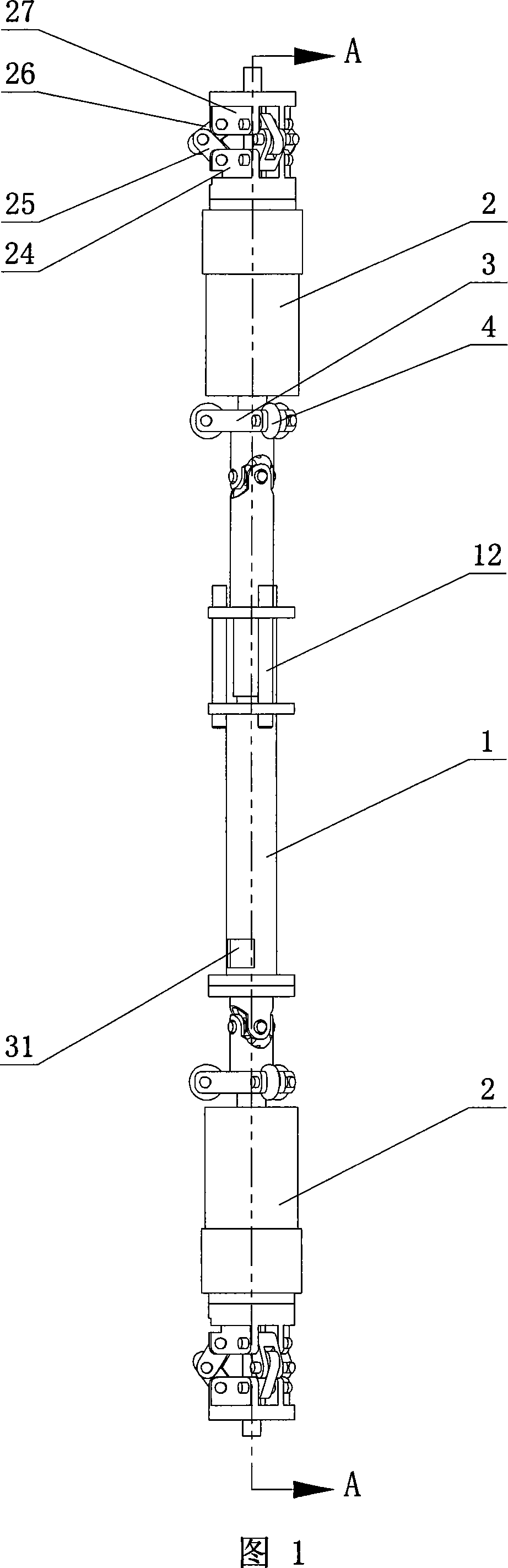

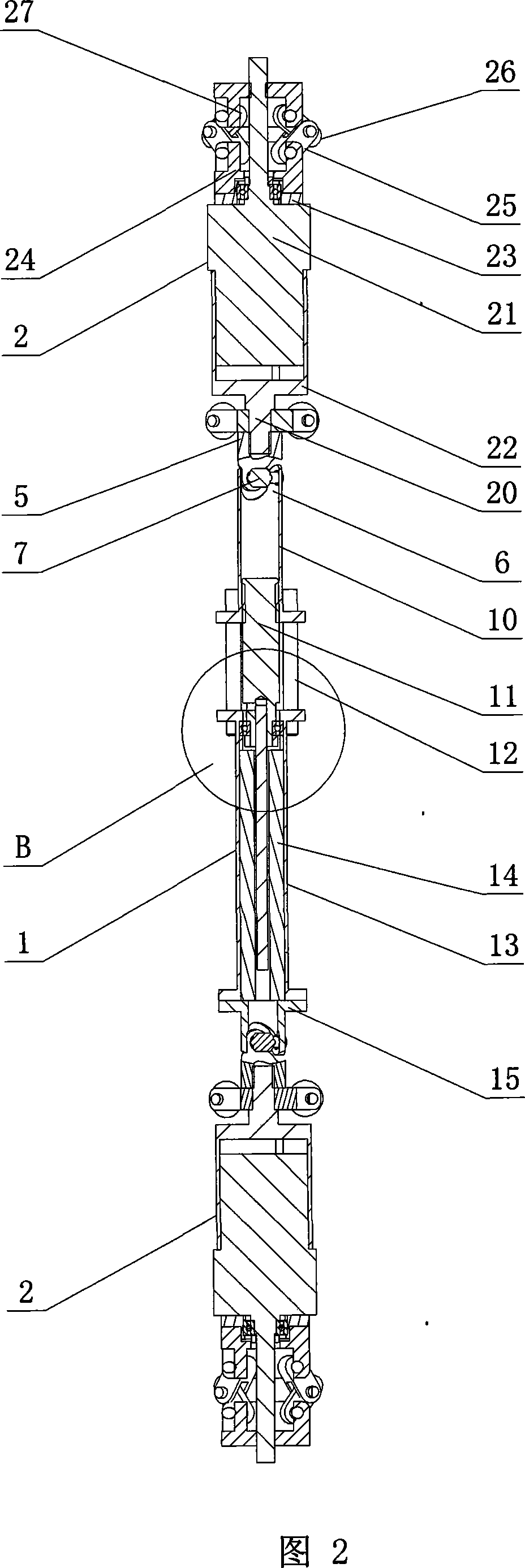

[0052] As shown in Figures 1 to 9, the peristaltic micro-pipe robot of the present invention can freely advance and retreat inside a micro-pipe with any inclined angle, and can crawl in a vertical pipe. It includes an intermediate telescopic part 1 and two One piece can be supported on the supporting part 2 in the tiny pipe, and the two supporting parts 2 are connected to the two ends of the middle telescopic part 1 respectively.

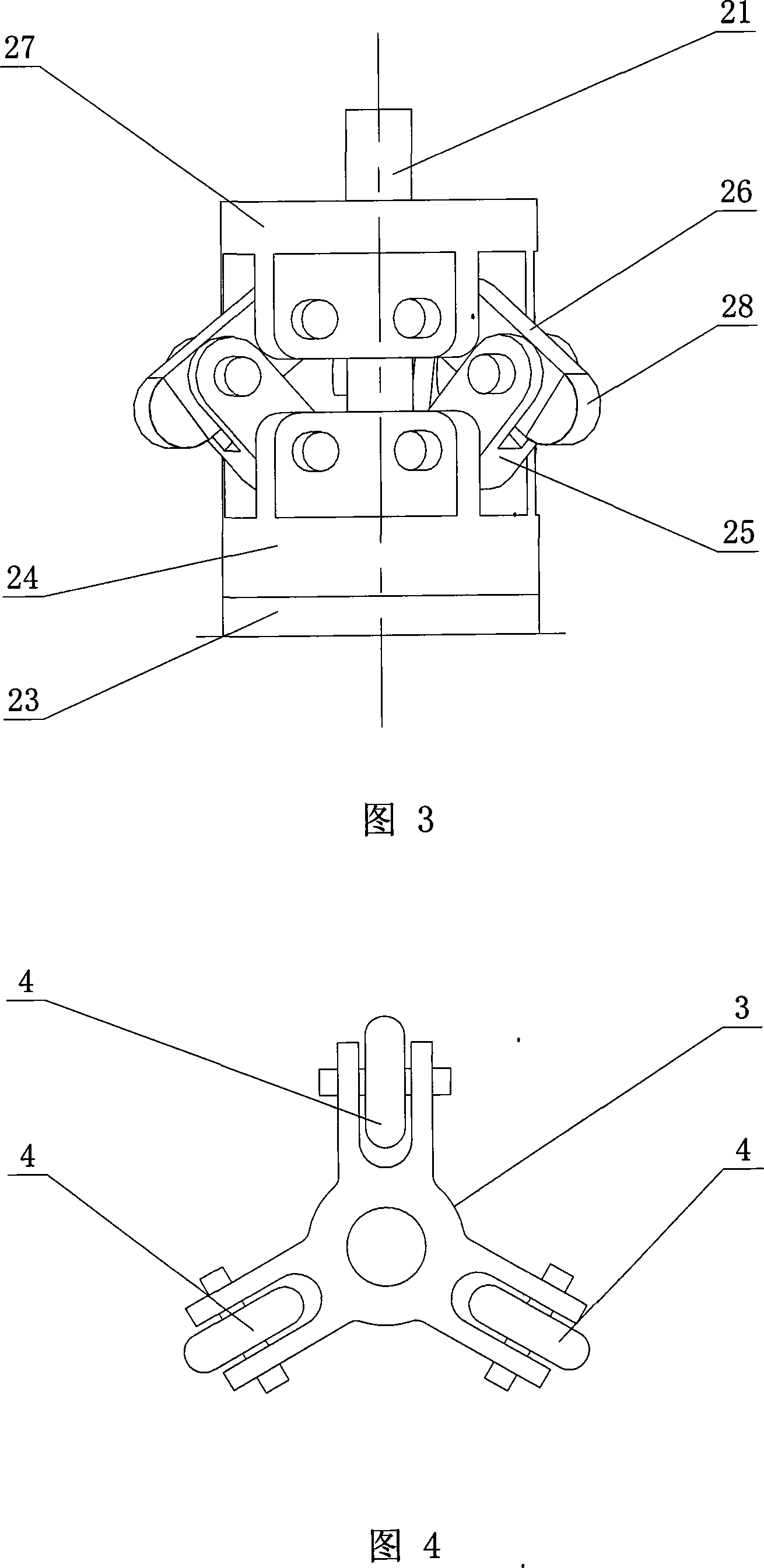

[0053]The supporting part 2 comprises a nut support 27 and a driving device which drives the nut support 27 to move forward and backward. The driving device comprises a small motor assembly 21, a small motor casing 22, a flange plate 23 and a hinged frame 24, and the output of the nut support 27 and the small motor assembly 21 The end of the shaft is screwed, one end of the small motor casing 22 is connected with the middle telescopic part 1, and the other end is sleeved on the small motor assembly 21, the flange 23 is supported on the output shaft o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com