Thick-wall pipe hydroforming device

An internal high-pressure forming and thick-walled pipe technology is applied in the field of pipe forming devices and internal high-pressure forming devices for thick-walled stepped pipes. It can solve the problem of high pressure sealing, reduce the cost of the mold, and reduce the high stress area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

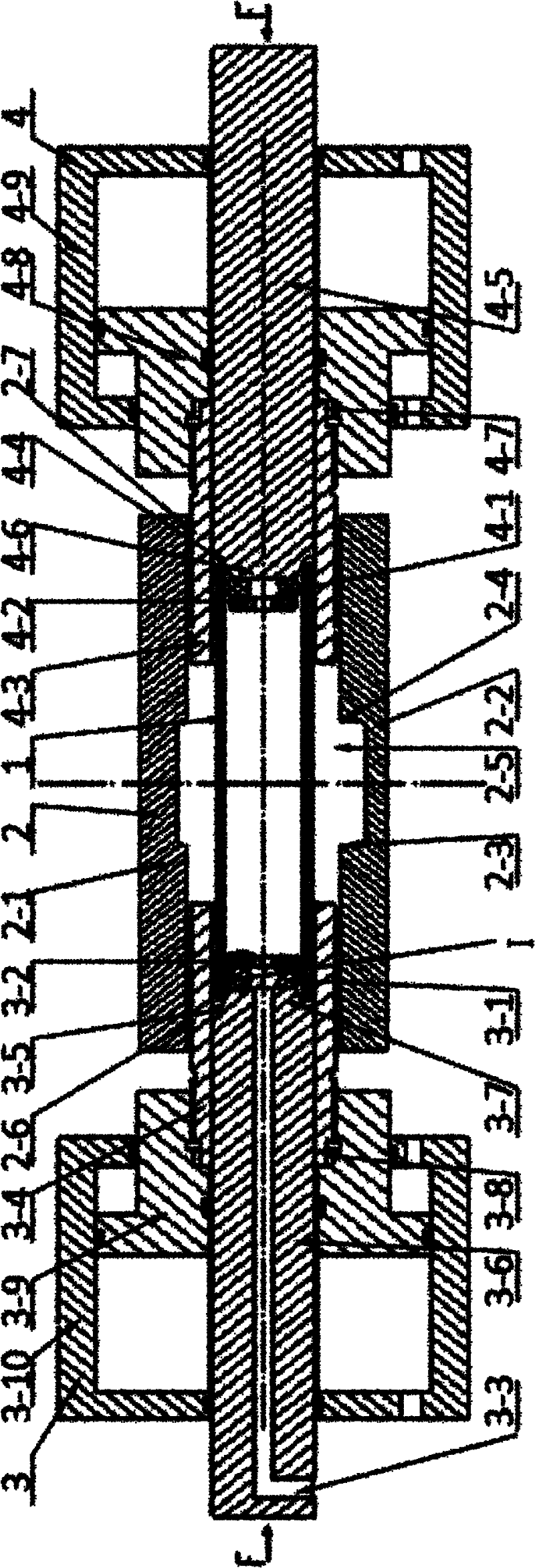

[0031] see figure 1 and Figure 6, the main body mold 2 is composed of an upper main body mold 2-1 and a lower main body mold 2-2, and the upper main body mold 2-1 and the lower main body mold 2-2 jointly form a molding cavity 2-5, and the left end of the main body mold is provided with a The left guide hole 2-6 communicated with the cavity 2-5, the right end is provided with the right guide hole 2-7 communicated with the cavity 2-5, the main body mold 2 is installed on the vertical press in the traditional way, and the left feed device 3 is provided with There are left punch 3-6, left additional hydraulic cylinder body 3-10, left additional hydraulic cylinder piston rod 3-9, left moving mold 3-4, left sealing ring 3-1, left gasket 3-2, right The feeding device 4 is provided with a right punch 4-5, a right additional hydraulic cylinder body 4-9, a right additional hydraulic cylinder piston rod 4-8, a right movable mold 4-3, a right sealing ring 4-1, and a right gasket 4 -2, ...

Embodiment 2

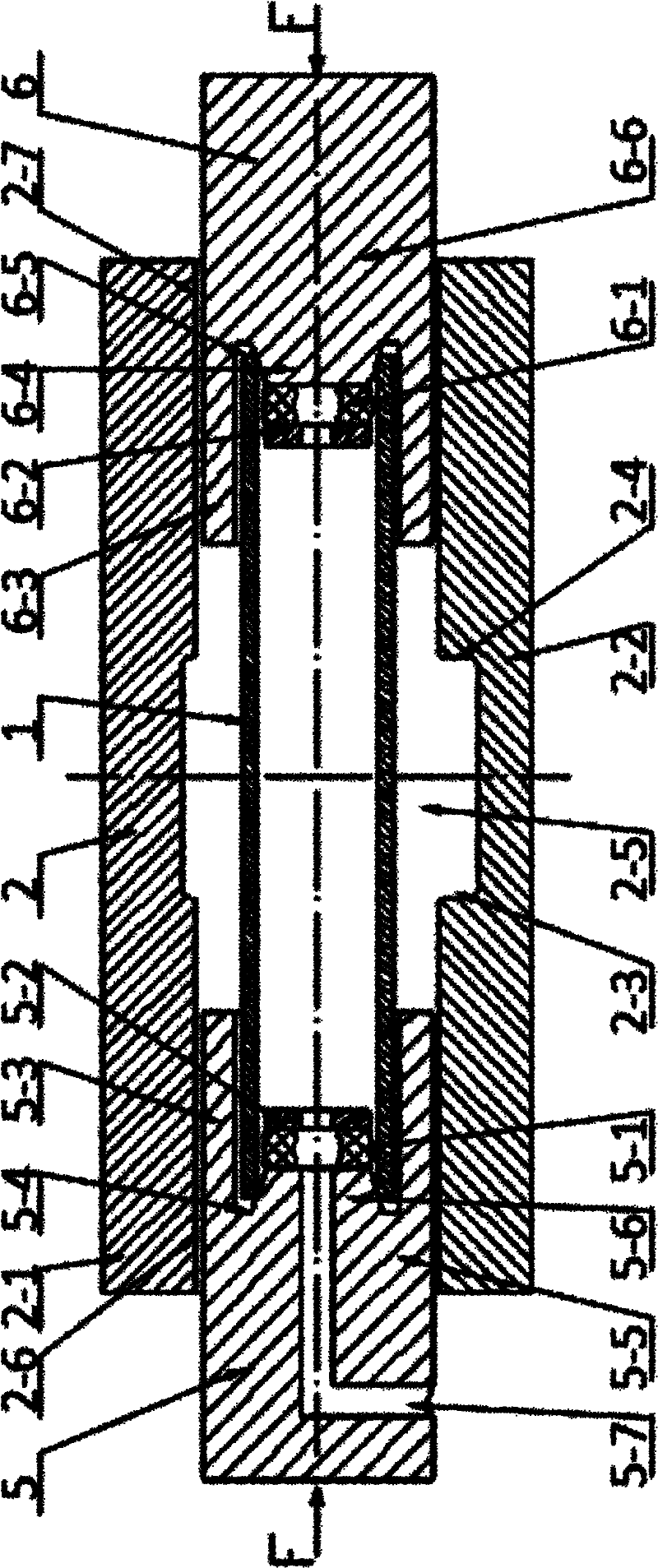

[0035] see figure 2 , the present embodiment is also based on the above-mentioned basic structure of the present invention, and its main difference from Embodiment 1 is: the left feeding device (such as figure 2 5) left moving mold (such as figure 2 5-3 in) and the left punch (such as figure 2 5-5) is made into one, the right feeding device (such as figure 2 6) of the right moving mold (such as figure 2 6-3) and the right punch (such as figure 2 6-6) is made into one, left moving mold (such as figure 2 5-3 in) and the left punch (such as figure 2 5-5) is installed on the horizontal press on the left side of the main mold 2, thereby eliminating the left additional hydraulic cylinder, and the right moving mold (such as figure 2 6-3 in) and the right punch (such as figure 2 6-6) is installed on the horizontal press on the right side of the main body mold 2, thereby saving the right additional hydraulic cylinder. After the device and the tube blank are fixed, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com