Novel water-cooling semi-sealed helical-lobe compressor

A compressor and semi-sealed screw technology, which is applied in the field of new water-cooled semi-sealed screw compressors, can solve the problems of short thrust bearing life, low bearing life, poor reliability, etc., achieve high life of sliding bearings, ensure motor temperature, and improve bearing performance. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

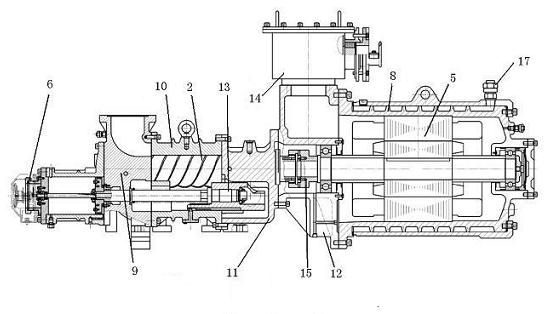

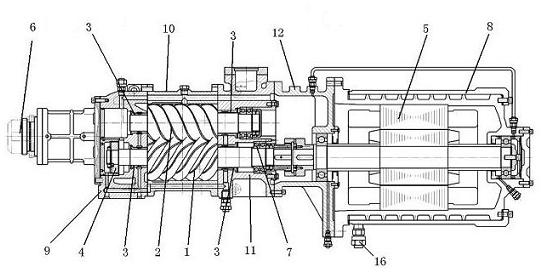

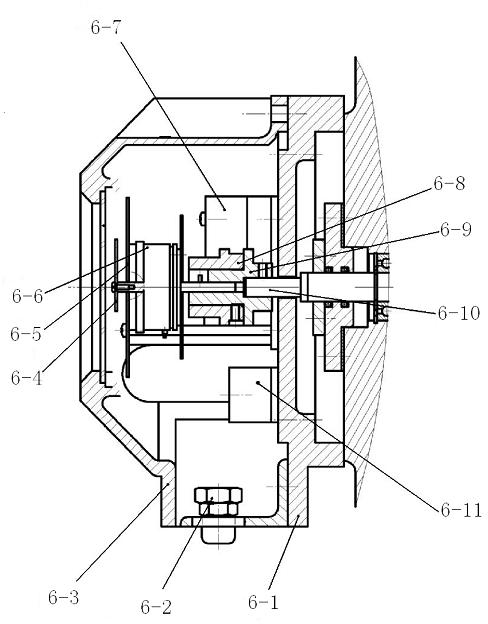

[0016] Example: A new type of water-cooled semi-hermetic screw compressor ( figure 1 , figure 2 ), the body 10 is provided with a male rotor 1 and a female rotor 2 that mesh with each other. The two ends of the body 10 are connected to the suction end seat 9 and the exhaust end seat 11, and both sides of the male rotor 1 and the female rotor 2 are respectively connected with In the sliding bearing 3, the male rotor 1 in the suction end seat 9 is connected with a balance piston 4 on the side close to the suction end, and the male rotor 1 and the female rotor 2 in the exhaust end seat 11 are connected with a thrust bearing 7 on the side close to the exhaust end. The body 10 is connected to a water jacket 8 through an intermediate body 12. The water jacket 8 is provided with a motor 5. The water jacket 8 is provided with a water inlet 16 and a water outlet 17. The cooling water circulates through the water inlet and outlet on the water jacket 8. The male rotor 1 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com