Method for preparing SAPO (Silico-Aluminophosphate) molecular sieve material with multi-level-hole structure

A molecular sieve and multi-stage pore technology, applied in the direction of molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problem that it is difficult to obtain the SAPO molecular sieve overall material with a multi-stage pore structure, and achieve easy control and preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

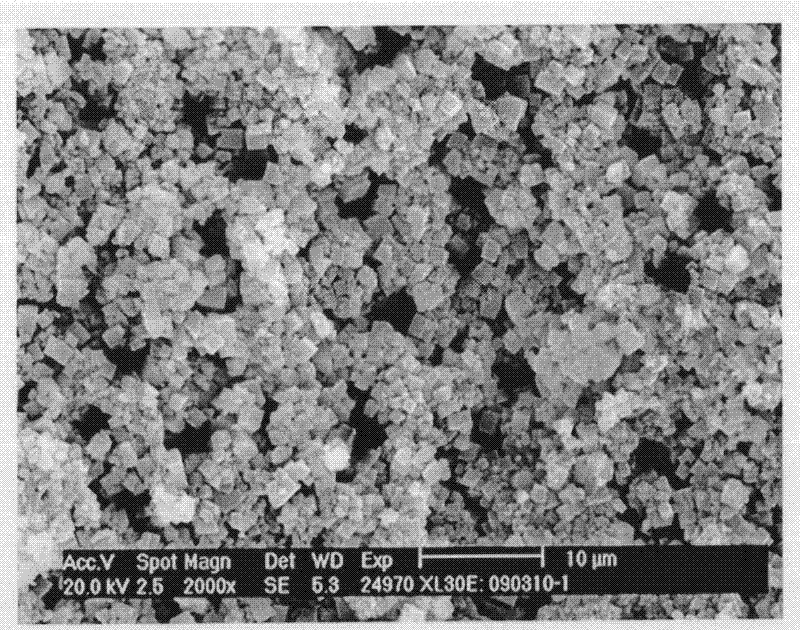

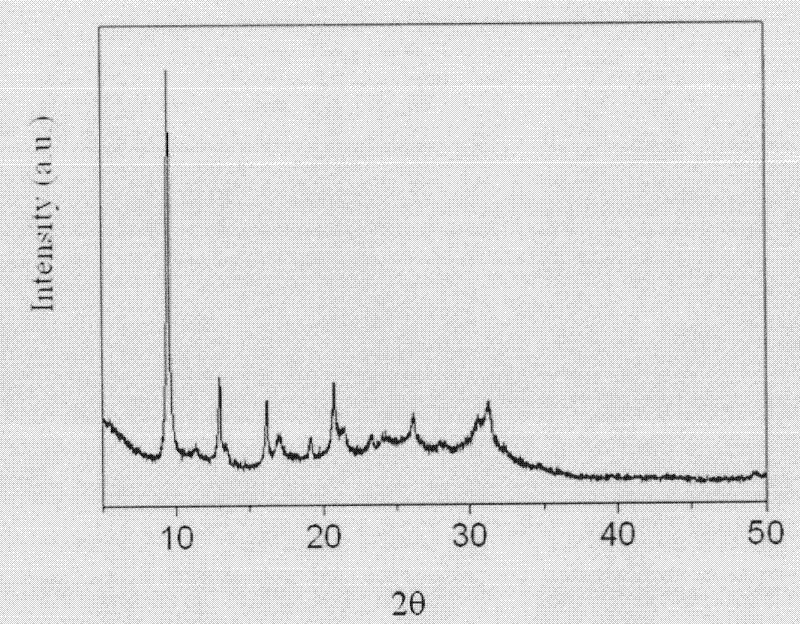

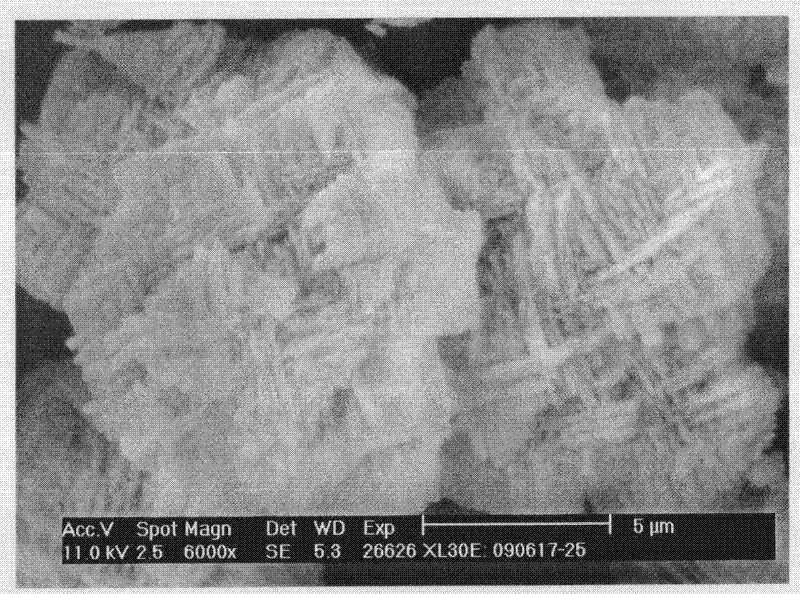

[0023] 6.63 grams of aluminum chloride hexahydrate, 0.82 grams of methyl orthosilicate, 1.5 grams of polyethylene glycol (molecular weight 10,000, referred to as PEG) and 3.36 grams of dipotassium hydrogen phosphate were added to the mixed solution of 4.35 grams of ethanol and 15.99 grams of water, Stir to dissolve at room temperature, add 5.00 g of propylene oxide (PO) to the mixed solution, and stir evenly. Pour the mixture into a mold to seal it, and place it in an oven at 60°C for 24 hours of aging. After taking it out, it was demoulded, dried at 60°C, and finally calcined at 550°C for 8 hours to obtain a silicon phosphorus aluminum oxide monolithic material. The obtained amorphous silicon phosphorus aluminum oxide monolith was immersed in the tetraethylammonium hydroxide solution for 24 hours, dried at room temperature for 24 hours, then placed on the upper part of the gas phase reactor, and water was added to the bottom of the reactor. Crystallization at 200°C for 3 day...

Embodiment 2

[0025] 6.63 grams of aluminum chloride hexahydrate, 0.82 grams of methyl orthosilicate, 1.5 grams of polyethylene glycol (molecular weight 10,000, referred to as PEG), and 7.83 grams of disodium hydrogen phosphate were added to a mixed solution of 4.35 grams of ethanol and 15.99 grams of water, Stir to dissolve at room temperature, then adjust the pH value to 8 with alkali, add 5.00 g of propylene oxide (PO) to the mixed solution, and stir evenly. Pour the mixture into a mold to seal it, and place it in an oven at 60°C for 24 hours of aging. After taking it out, it was demoulded, dried at 60°C, and finally calcined at 550°C for 8 hours to obtain a silicon phosphorus aluminum oxide monolithic material. Place the obtained amorphous silicon phosphorus aluminum oxide monolith in the upper part of the gas phase reactor, add tetraethylammonium hydroxide solution at the bottom of the reactor, and crystallize at 200°C for 3 days; after the reaction, the reactor is cooled in a natural ...

Embodiment 3

[0027] 6.63 grams of aluminum chloride hexahydrate, 0.82 grams of methyl orthosilicate, 1.5 grams of polyethylene glycol (molecular weight 10,000, referred to as PEG), and 5.83 grams of dipotassium hydrogen phosphate were added to a mixed solution of 4.35 grams of ethanol and 15.99 grams of water, Stir to dissolve at room temperature, then adjust the pH value to 8 with alkali, add 5.00 g of propylene oxide (PO) to the mixed solution, and stir for 1 minute. Pour the mixture into a mold to seal it, and place it in an oven at 60°C for 24 hours of aging. After taking it out, it was demoulded, dried at 60°C, and finally calcined at 550°C for 8 hours to obtain a silicon phosphorus aluminum oxide monolithic material. The obtained amorphous silicon phosphorus aluminum oxide monolith was immersed in the tetraethylammonium hydroxide solution for 24 hours, dried at room temperature for 24 hours, then placed on the upper part of the gas phase reactor, and water was added to the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com