SAPO (silicoaluminophosphate) molecular sieve with RHO skeleton structure and preparation method thereof

A framework structure, molecular sieve technology, applied in molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] In the method for preparing SAPO molecular sieves with RHO structure (RHO-SAPO) provided by the present invention, the initial gel needs to be pretreated to make xerogel, or a surfactant is assisted in the preparation of the initial gel.

[0047] The RHO-SAPO molecular sieve synthesized by the invention is characterized in that the molecular sieve crystallization process is a dynamic crystallization process.

Embodiment 1

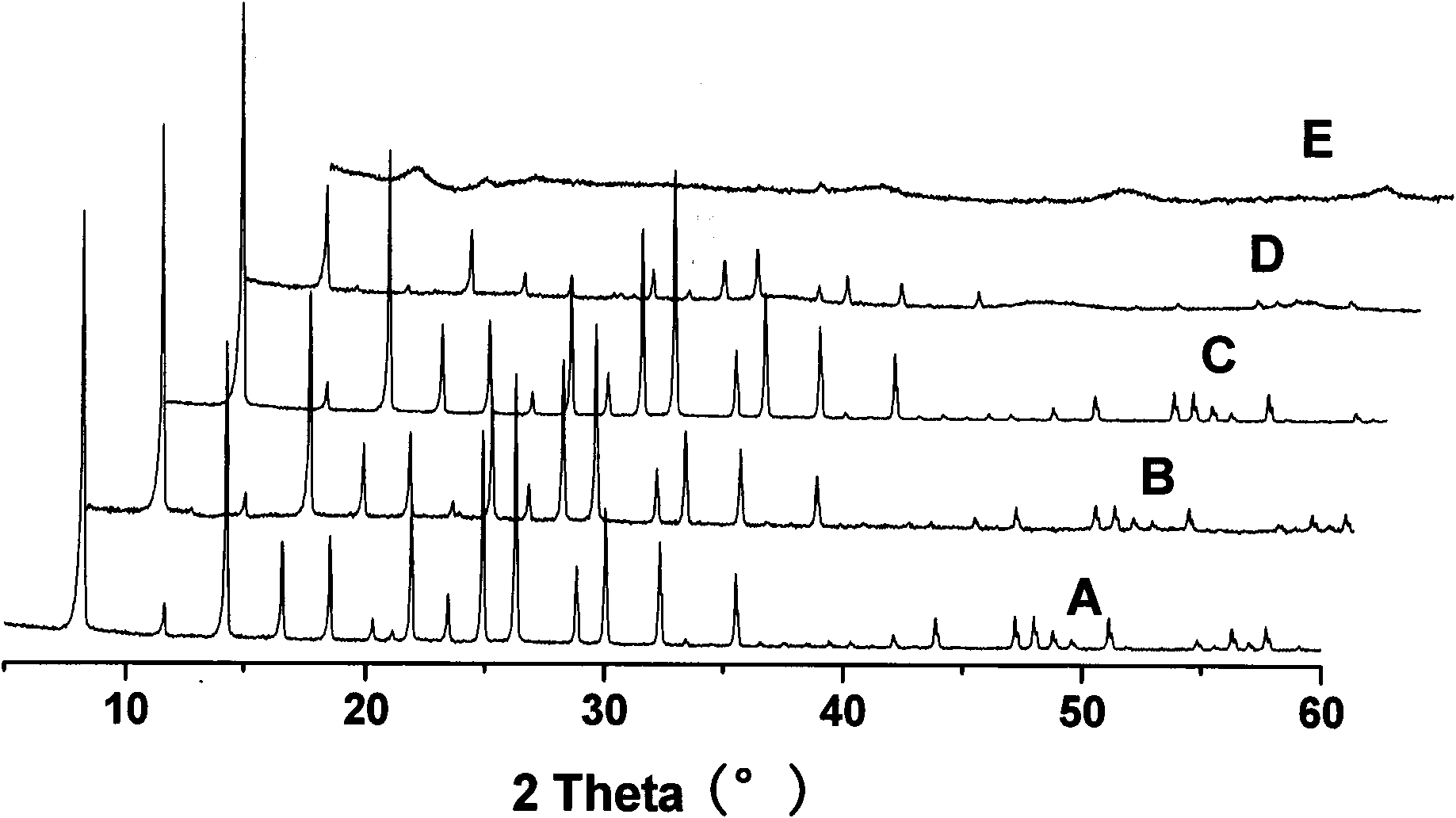

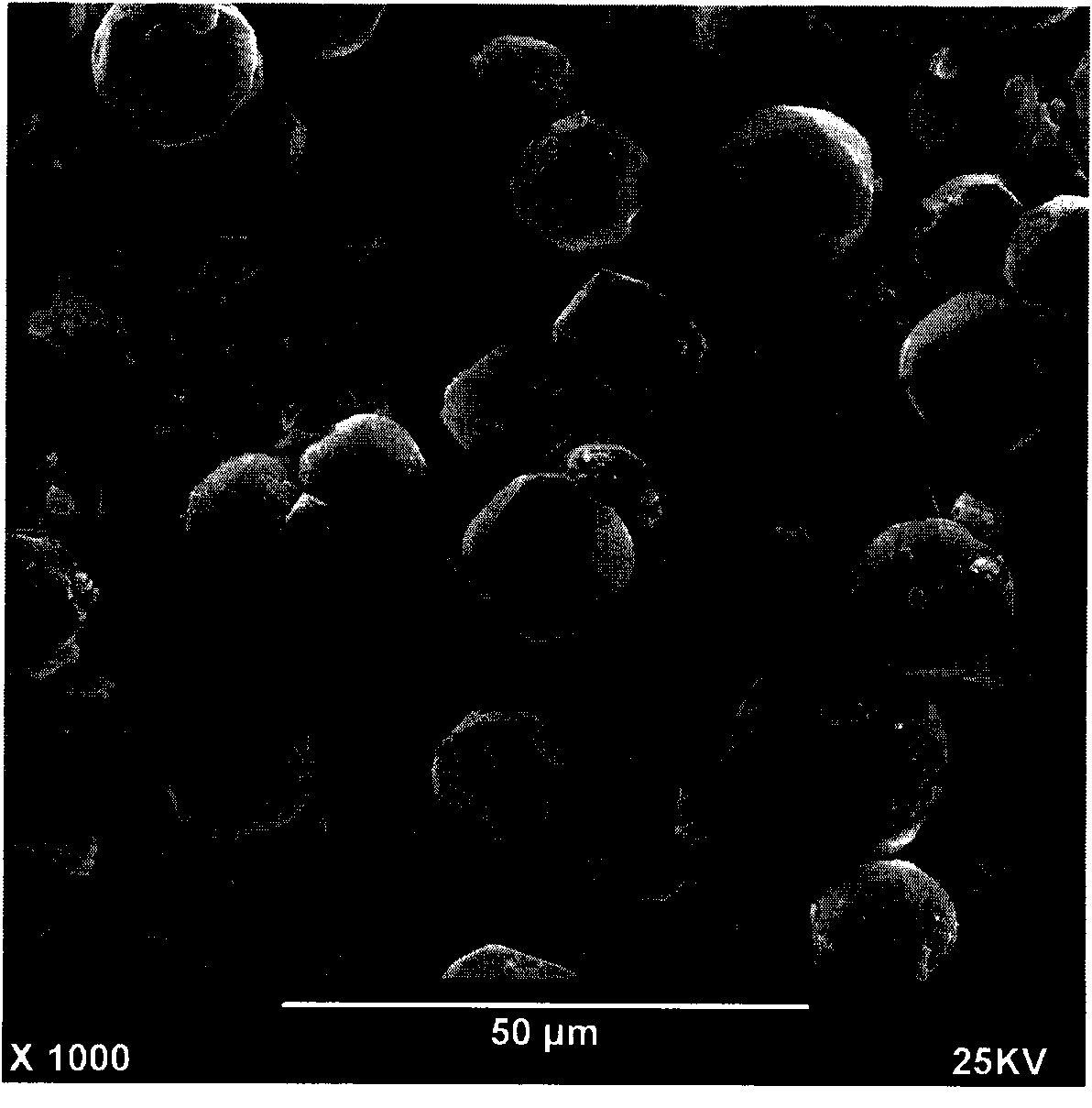

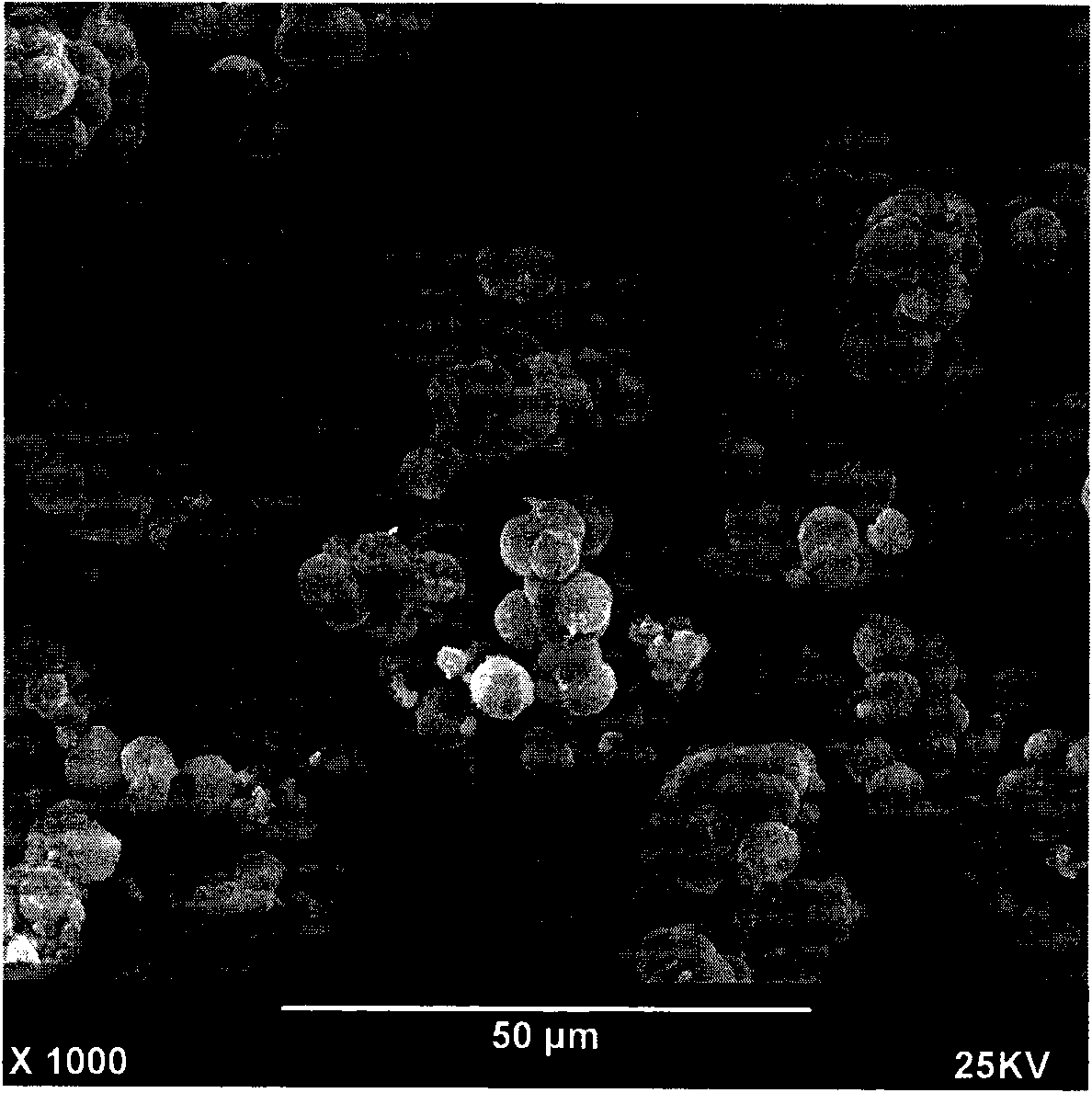

[0050] 10.48g activated alumina (containing Al 2 o 3 73.5wt%) was dissolved in 78ml deionized water, and 8.94g orthophosphoric acid (containing H 3 PO 4 85wt%) and 8.34g silica sol (containing SiO 2 40wt%). Then, 2.40 g of cetyltrimethylammonium bromide (CTAB) was dissolved and added to the above gel system, stirred vigorously to make the mixture uniform, and finally 7.80 g of diethylamine was added to the gel system. The homogeneously mixed gel mixture was transferred into a stainless steel synthesis kettle, sealed, and dynamically crystallized at 200° C. and autogenous pressure for 72 hours. The solid product was centrifuged, washed with deionized water until neutral, dried in air at 100°C, and calcined in air at 550°C for 5 hours to obtain the RHO-SAPO molecular sieve. Its X-ray spectrum (XRD) see figure 1 Curve A indicates that the synthesized molecular sieve has a RHO structure, and the analysis results are shown in Table 1. The resulting sample was characterized...

Embodiment 2

[0052] In Example 1, only 10.48g of activated alumina was changed to 17.32g of aluminum isopropoxide, and the remaining components and crystallization conditions were unchanged. The obtained samples were analyzed by XRD diffraction, and the results were consistent with the data in Table 1, indicating that the samples synthesized by this method were molecular sieves with RHO structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com