Preparation method for silicoaluminophosphate (SAPO)-34 molecular sieve with small crystal particle

A technology of SAPO-34 and molecular sieve, which is applied in the direction of molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problem of large grain size of SAPO-34

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

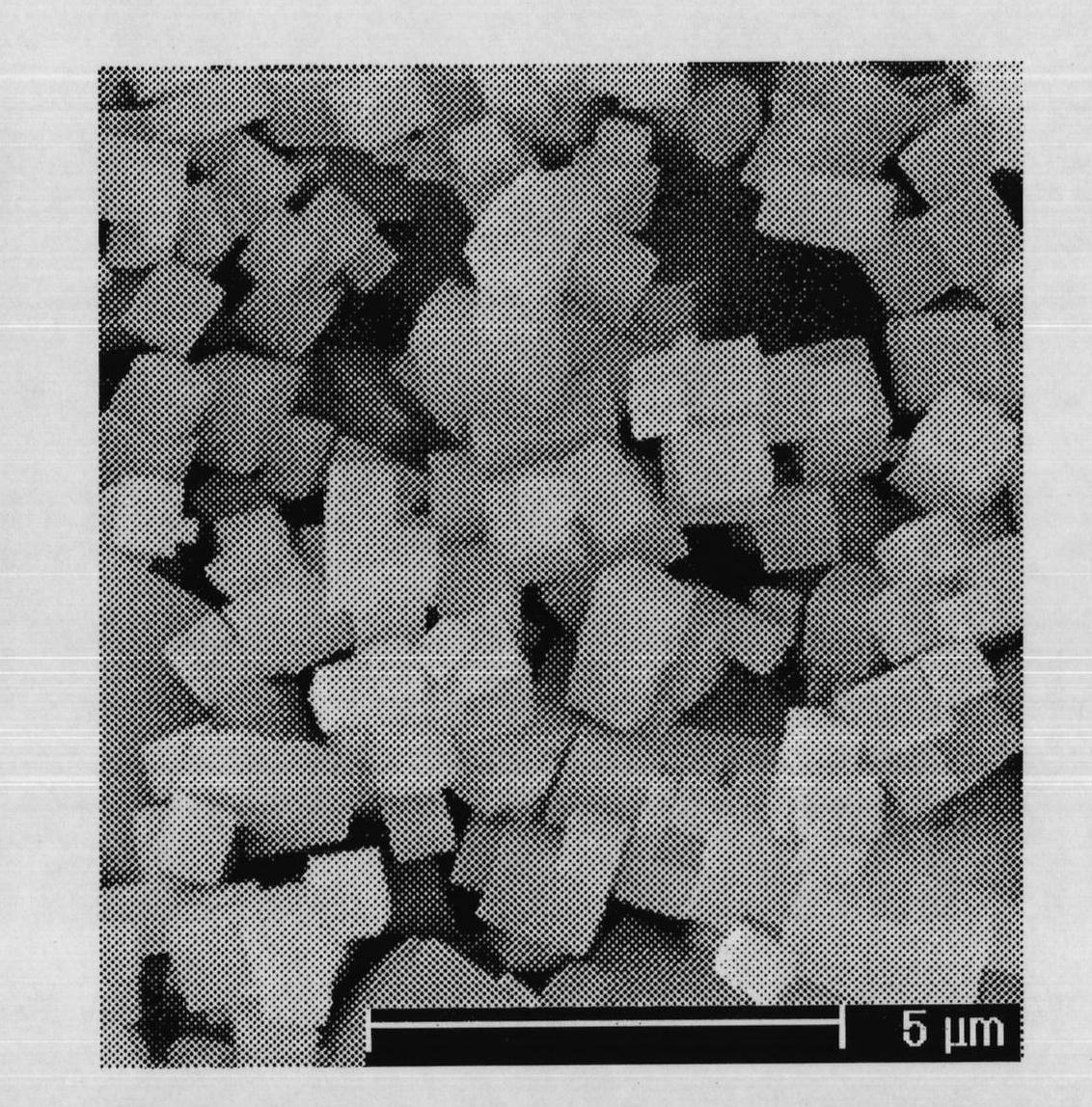

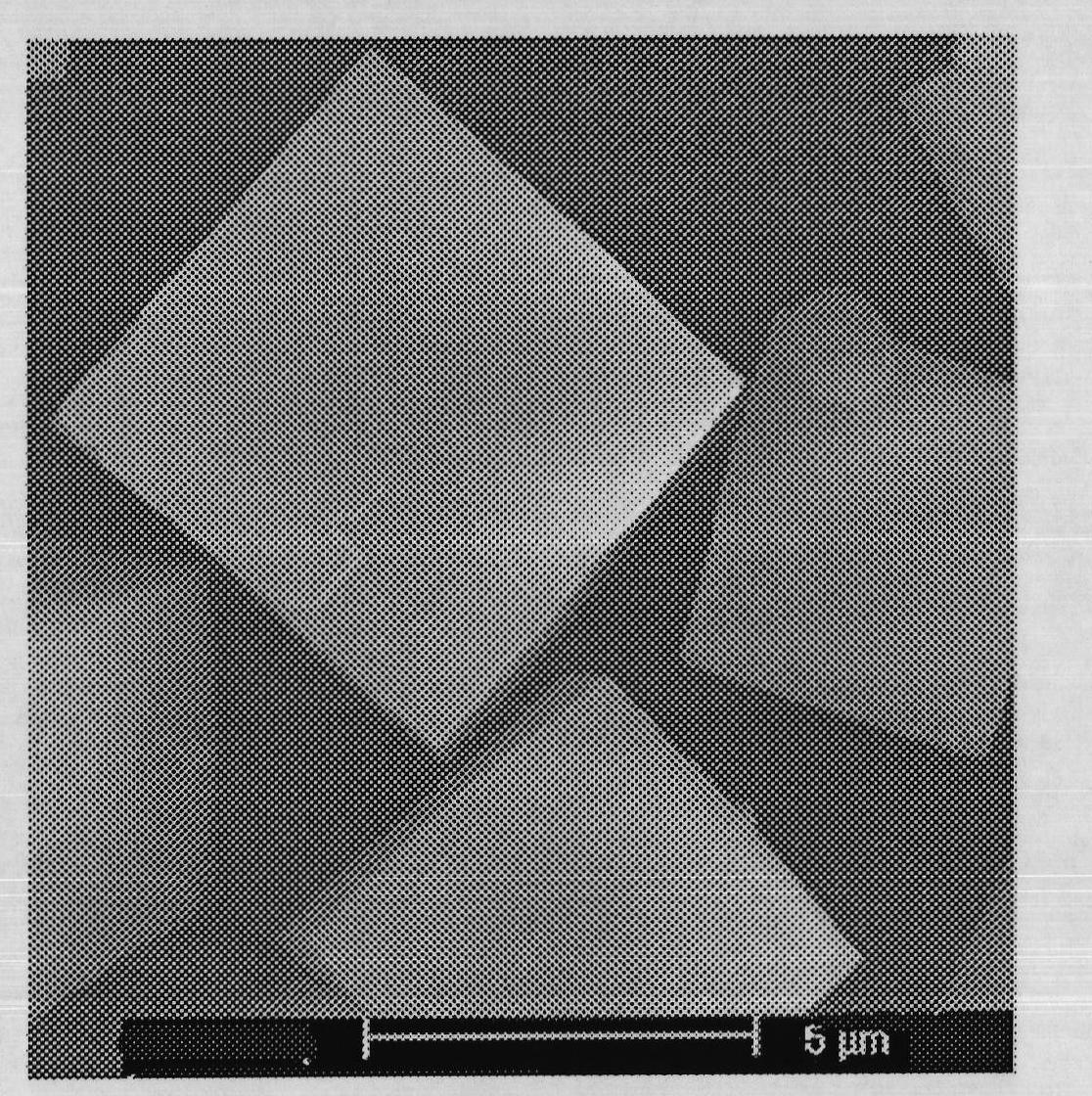

Embodiment 1

[0024] 12.1 g γAl 2 o 3 Mix with 35.0 grams of deionized water to form solution a; 23.3 grams of orthophosphoric acid (85% by weight), 0.2 gram of hydrofluoric acid (40% by weight), and 37.5 grams of deionized water are mixed to form solution b; a and b are mixed Stir at room temperature for 2 hours to form a homogeneous solution c; keep stirring, add 31 grams of triethylamine, 4.5 grams of silica sol and 27.0 grams of deionized water to c in sequence, and get the initial gel mixture of synthetic SAPO-34 molecular sieve after fully stirring ; This mixture was crystallized at 200° C. for 12 hours, and the quenched crystallization director was taken out; an initial gel mixture was prepared in the same way as described above, and the ratio of 1:1 with the crystallization director (volume ratio) mixed to form solution d; liquid d was crystallized at 200°C for 24 hours, and the product was centrifuged to obtain a solid product, which was dried in an oven at 110°C overnight. XRD te...

Embodiment 2~5

[0036] The operation steps and experimental conditions are the same as in Example 1, except that the crystallization time t of the crystallization directing agent is changed. The results are shown in Table 1.

[0037] Table 1

[0038]

[0039] Note: Diene is "ethylene + propylene".

Embodiment 6

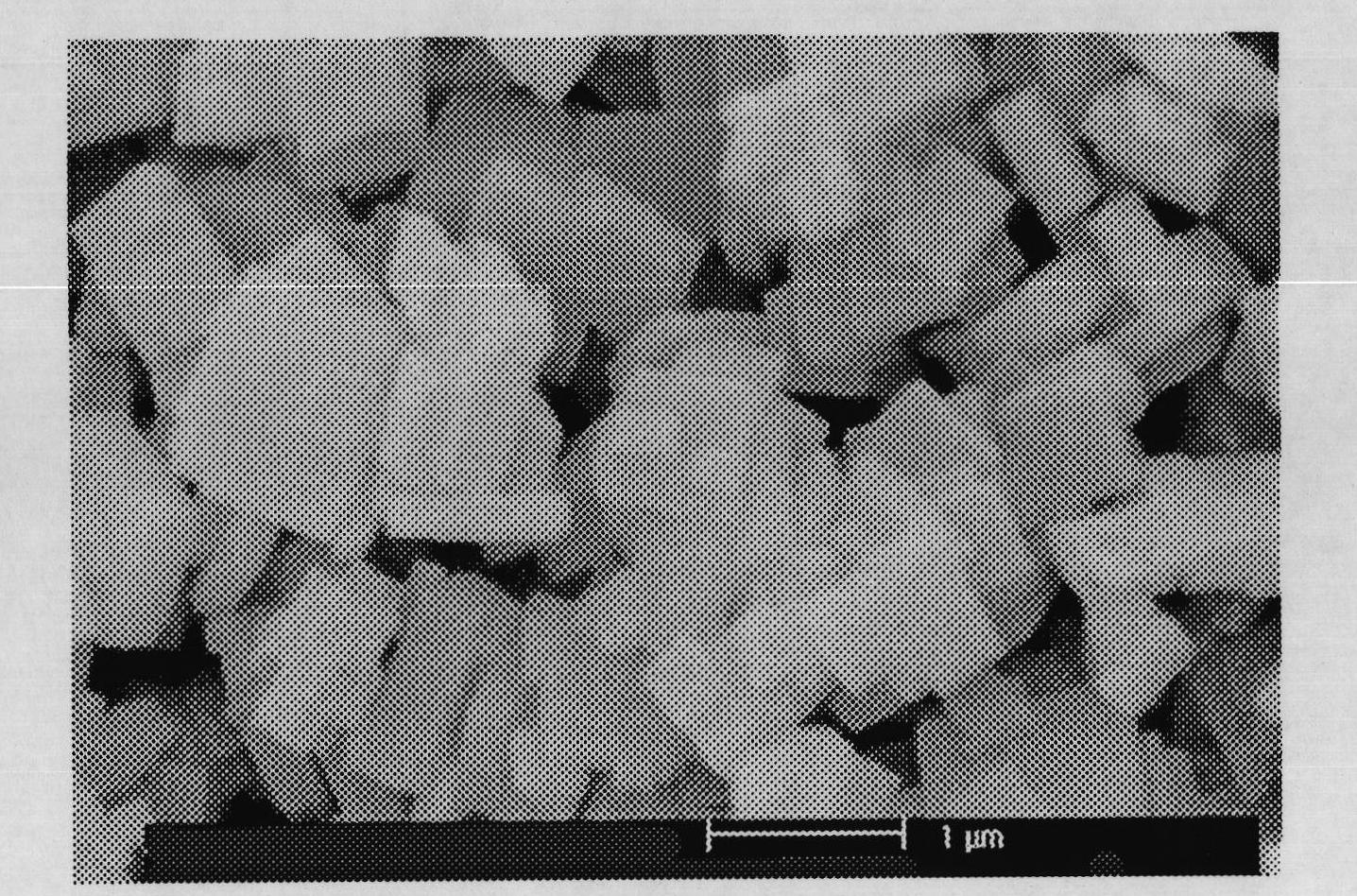

[0041] The crystallization directing agent was prepared at 170° C., and the other operating procedures and experimental conditions were the same as in Example 1. The particle size of the obtained product SAPO-34 was about 0.9 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com