Method for preparing AlPO4 or SAPO molecular sieve

A technology of molecular sieve and methyl imidazolium ion, applied in the direction of molecular sieve characteristic aluminum phosphate, molecular sieve characteristic silicoaluminophosphate, phosphorus compound, etc., can solve the problem of difficult to obtain pure-phase products, and achieve the effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 0.5g of n-dipropylamine was added to a round bottom flask containing 40g of 1-butyl-3-methylimidazolium bromide ionic liquid, and 1.0g of 85% H was added at 60°C with stirring 3 PO 4 After stirring for 30 minutes, 1.0 g of aluminum isopropoxide was added, and after stirring for 30 minutes, 0.5 g of 15% HF was added.

[0029] Transfer the round-bottomed flask containing the reaction mixture to an oil bath and heat up to 200° C., continue to stir and react for 1 hour, take out the reactor and cool to room temperature, and filter out the solid sample. The solid sample was washed repeatedly with acetone and water and dried at 100°C. Then the molecular sieve powder was calcined at 550°C in an air atmosphere for 8 hours to obtain AlPO 4 Molecular sieve. After the filtrate was rotary evaporated, it was recrystallized with dichloromethane for the next use.

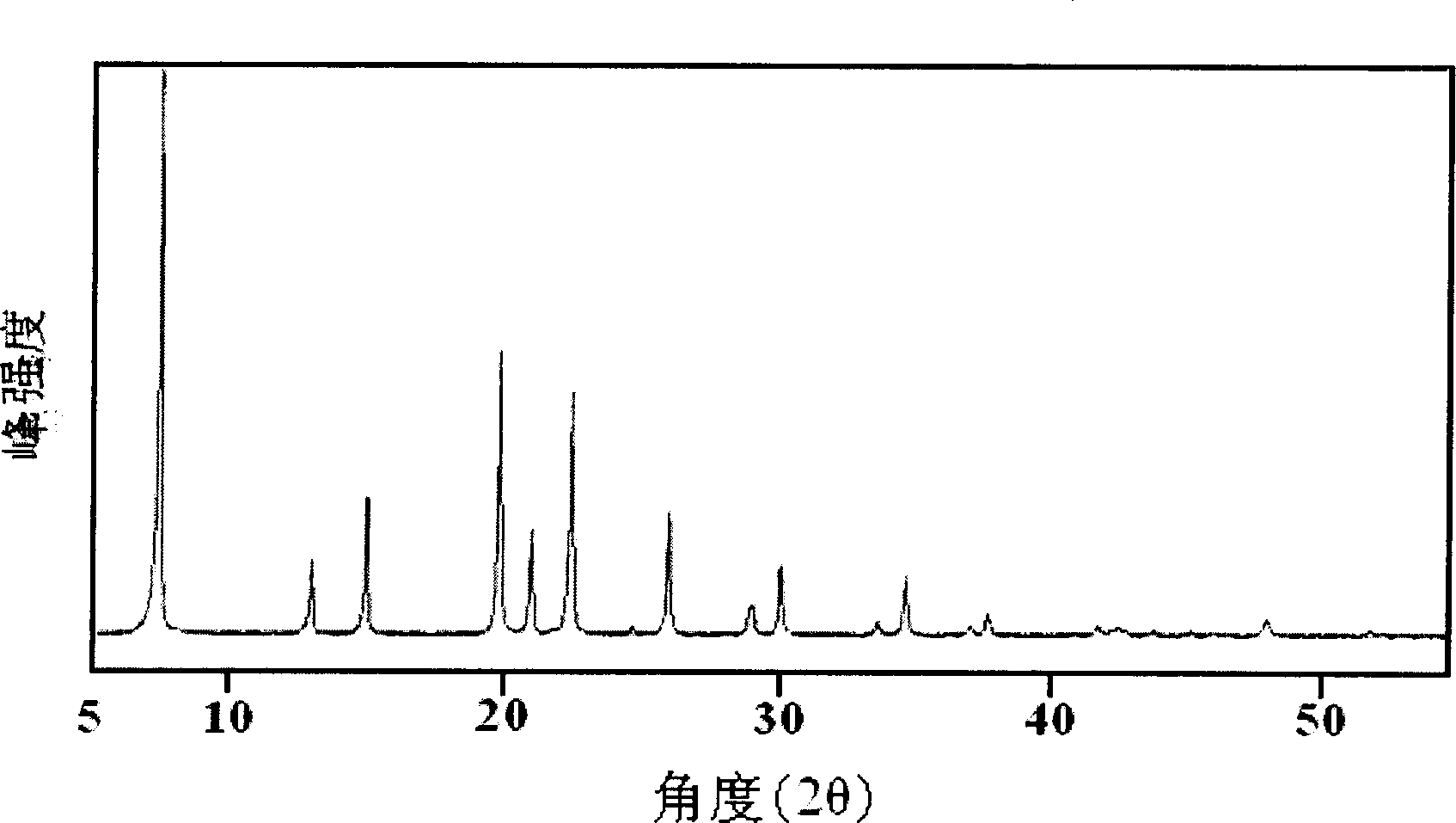

[0030] The XRD spectrum of the obtained sample is as figure 1 As shown, its crystal phase is the same as AlPO obtain...

Embodiment 2

[0032] 0.4g of triethylamine was added to a round bottom flask containing 30g of 1-hexyl-3-methylimidazolium bromide ionic liquid, and 1.0g of 85% H was added at 70°C with stirring 3 PO 4 After stirring for 30 minutes, 1.0 g of aluminum isopropoxide was added, and after stirring for 30 minutes, 0.5 g of 15% HF was added.

[0033] The round-bottomed flask containing the reaction mixture was transferred to an oil bath and heated to 150° C., and the reaction was continued to stir for 2 hours. The reactor was taken out and cooled to room temperature, and the solid sample was filtered out. The solid sample was washed repeatedly with acetone and water and dried at 100°C. Then the molecular sieve powder was calcined at 550°C in an air atmosphere for 8 hours to obtain AlPO 4 Molecular sieve. After the filtrate was rotary evaporated, it was recrystallized with dichloromethane for the next use.

[0034] The XRD spectrum of the obtained sample is similar to the XRD spectrum of the sa...

Embodiment 3

[0036] 0.4g of triethylamine was added to a round bottom flask containing 30g of 1-butyl-3-methylimidazolium bromide ionic liquid, and 1.0g of 85% H was added at 70°C with stirring 3 PO 4 After stirring for 30 minutes, 1.5 g of aluminum isopropoxide was added, and after stirring for 20 minutes, 0.5 g of 15% HF was added.

[0037] The round bottom flask containing the reaction mixture was transferred to an oil bath and the temperature was raised to 220° C., and the reaction was continued to stir for 3 hours. The reactor was taken out and cooled to room temperature, and the solid sample was filtered out. The solid sample was washed repeatedly with acetone and water and dried at 100°C. Then the molecular sieve powder was calcined at 550°C in an air atmosphere for 8 hours to obtain AlPO 4 Molecular sieve. After the filtrate was rotary evaporated, it was recrystallized with dichloromethane for the next use.

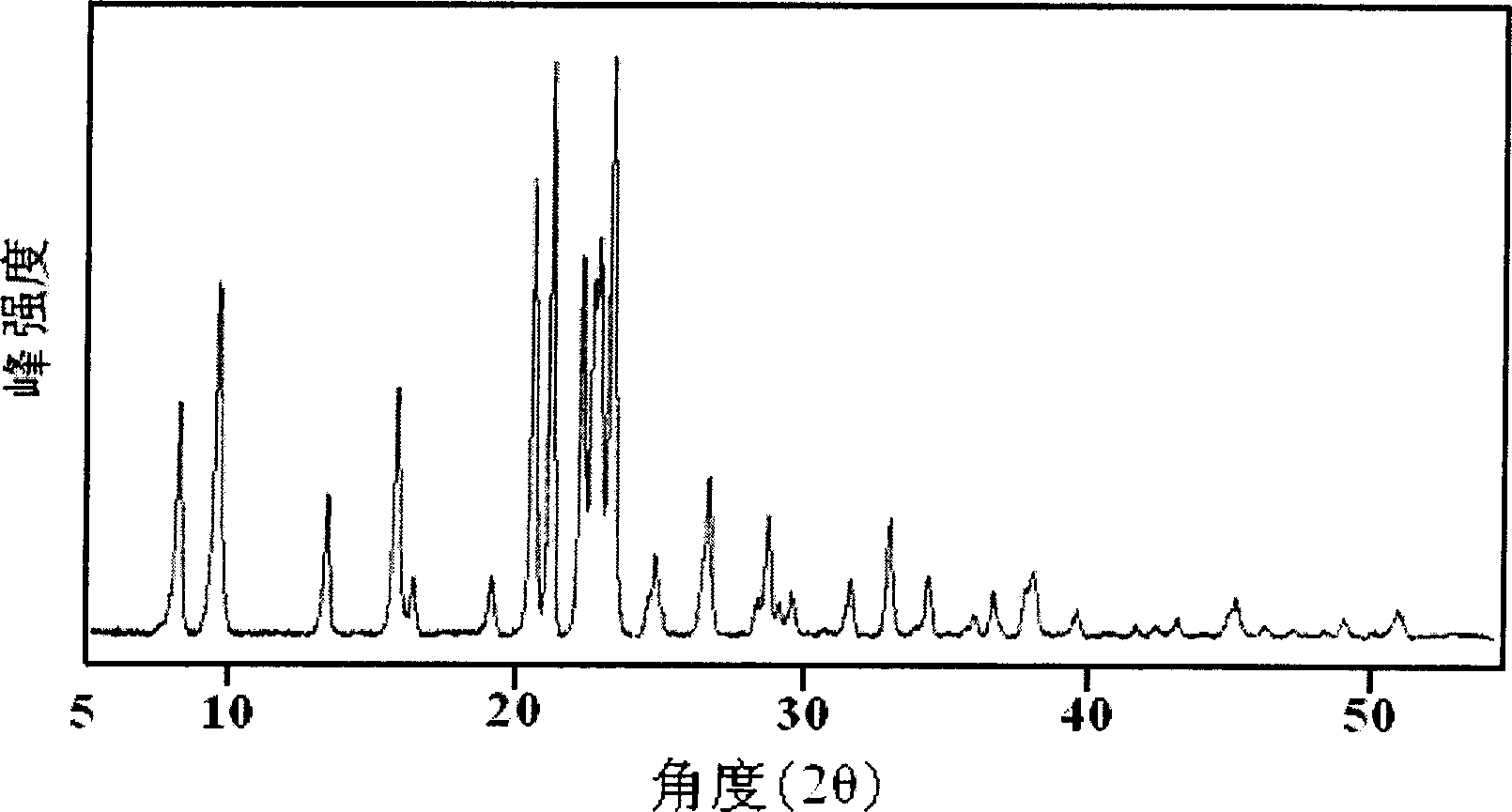

[0038] The XRD spectrum of the obtained sample is as figure 2 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com