Preparation of fine grain SAPO-34 molecular sieve

A technology of SAPO-34 and molecular sieve, which is applied in the direction of molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problems of complex synthesis process, cost increase, aging, etc., achieve large specific surface area, improve performance, The effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

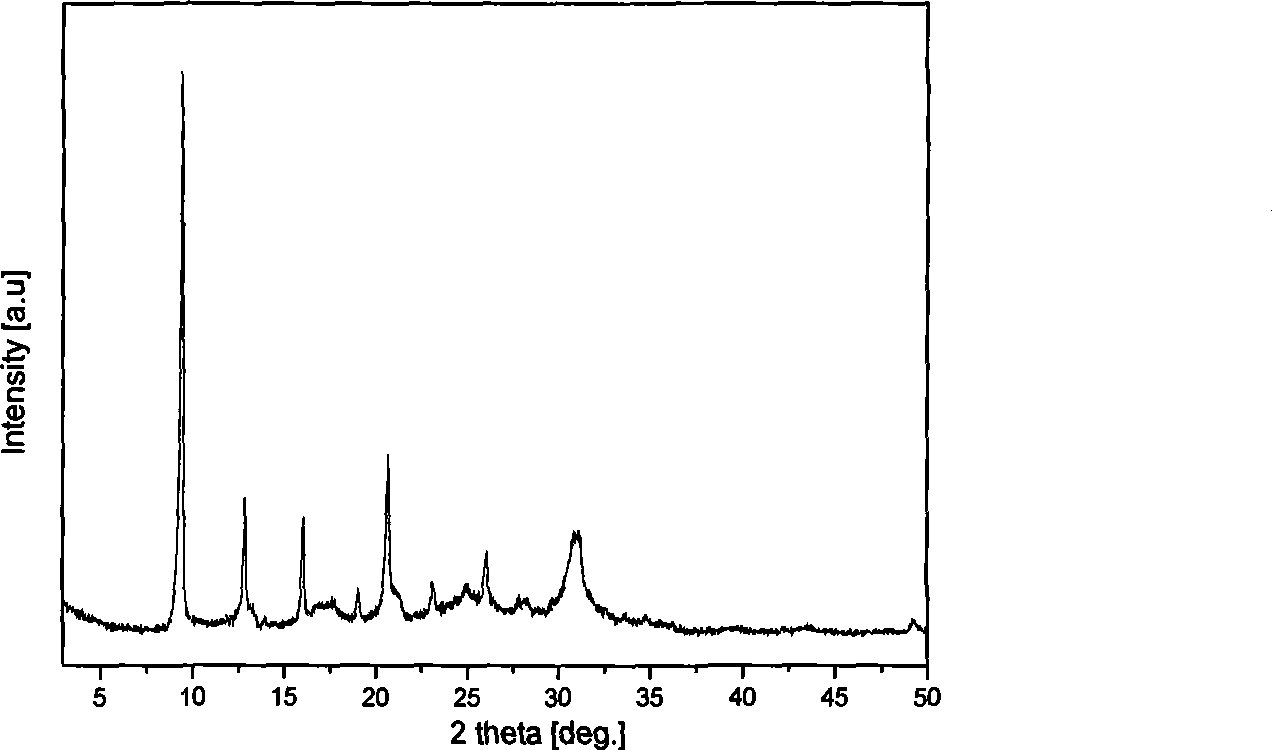

Embodiment 1

[0025] The raw material pseudo-boehmite (containing Al 2 o 3 Add 5.50 g of 67.4% wt) into a 70 ml synthesis kettle, then add 16 ml of deionized water, and stir evenly. Phosphoric acid (containing H 3 PO 4 85%wt) 8.30g and deionized water 16ml. Stir vigorously for about 2 hours, then add silica sol (containing SiO 2 30%wt) 5.76g, add 10.93g of triethylamine, and stir for about 2 hours until a uniform colloid is formed. Put the reactor into the oven, raise the temperature to 110°C, keep the temperature constant for 2 hours, then raise the temperature to 200°C, keep the temperature constant for 24 hours, after cooling, separate the solid from the mother liquor, wash the solid several times with deionized water, and set the temperature at 110°C Dry in the air to obtain SAPO-34 molecular sieve raw powder. Its crystallinity and particle size are shown in Table 1.

Embodiment 2

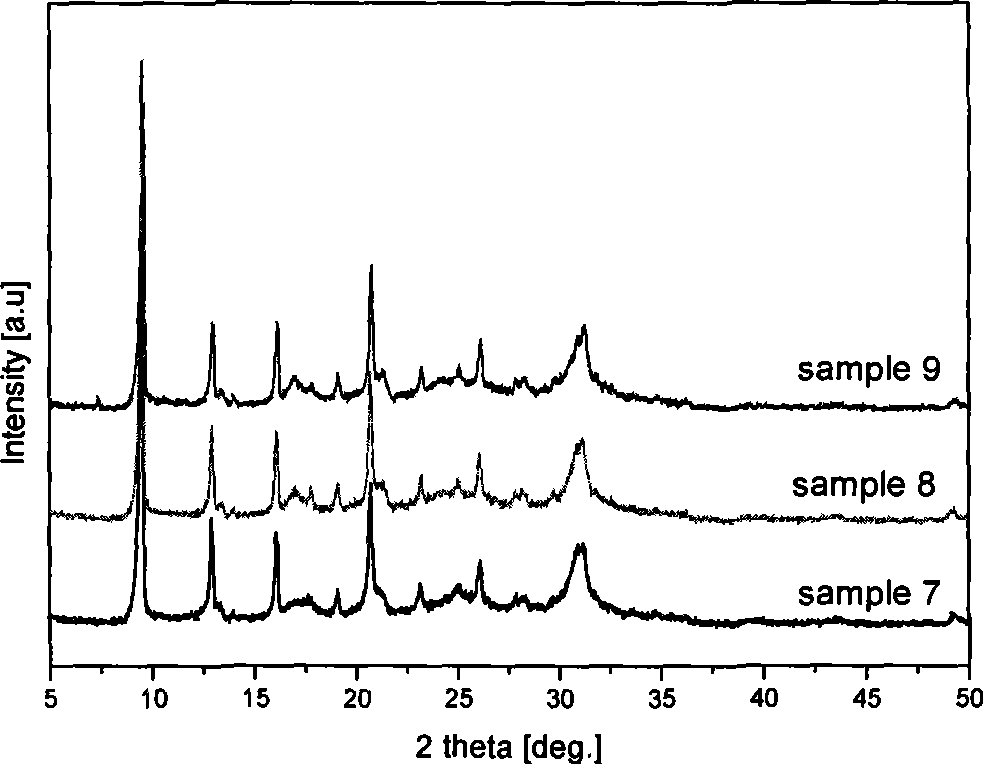

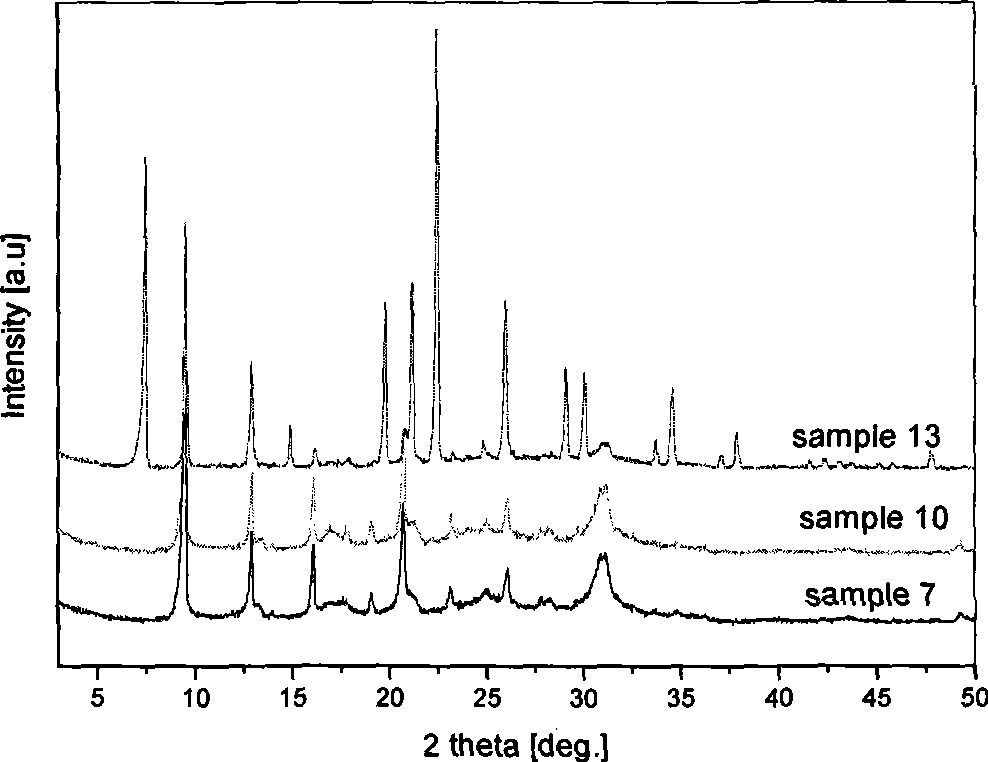

[0027] In Example 1, only the amount of silica sol added was changed from 5.76 g to 2.88 g, and the remaining components and operations were kept unchanged to obtain a pure-phase SAPO-34 molecular sieve raw powder. Calcined at 550°C for 6 hours to obtain SAPO-34 molecular sieve. Its crystallinity and particle size are shown in Table 1.

Embodiment 3

[0029] In Example 1, only the amount of silica sol added was increased from 5.76 to 8.64 g, and the rest of the components and operations remained unchanged to obtain a pure-phase SAPO-34 molecular sieve powder. Calcined at 550°C for 6 hours to obtain SAPO-34 molecular sieve. Its crystallinity and particle size are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com