Nano SAPO (silicoaluminophosphate)-34 molecular sieve with spherical or flaky appearance, synthetic method thereof, catalyst prepared by same and application thereof

A SAPO-34, molecular sieve technology, applied in molecular sieve catalyst, molecular sieve and alkali exchange phosphate, hydrocarbon production from oxygen-containing organic compounds, etc., can solve the problem of single shape and size of SAPO-34 molecular sieve, and achieve long single-pass catalytic life. , The synthesis is simple and fast, the effect of various grain morphologies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

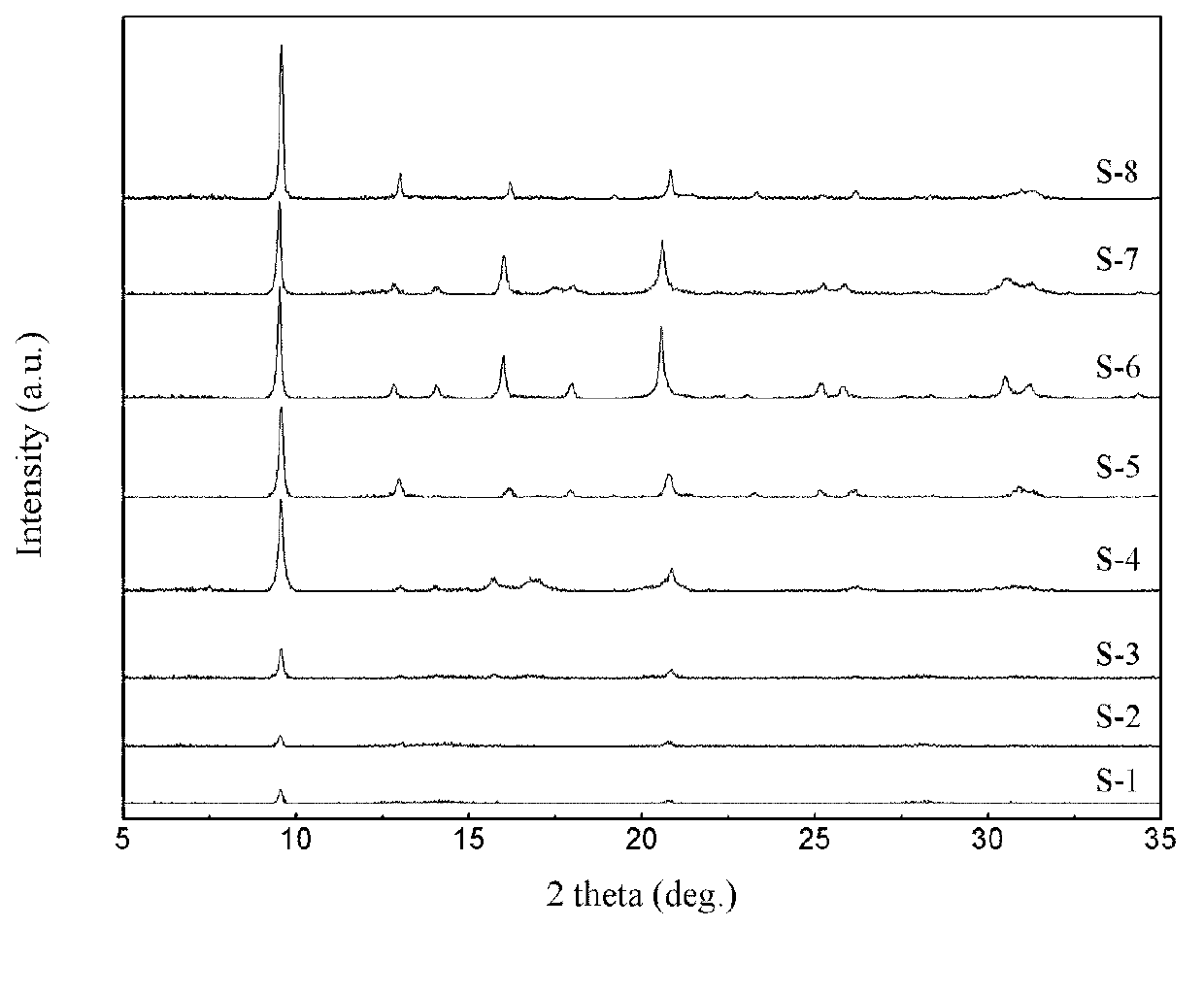

[0035]Mix 48.7g of pseudo-boehmite, 27.5g of silica sol, and 50.0g of deionized water for 1 hour at room temperature to obtain a mixed solution A; add 83.7g of orthophosphoric acid and 322.5g of tetraethyl hydroxide to the mixed solution A in turn ammonium and continue to stir for 1 hour to obtain mixed solution B, which is the initial gel mixture of SAPO-34 molecular sieves. The initial gel mixture was put into a high-pressure reactor with a polytetrafluoroethylene liner. After sealing, the reactor was placed in a microwave reactor, heated to 165° C., and crystallized at a constant temperature under autogenous pressure for 0.75 hours. After the reaction kettle is cooled, the solid product is centrifuged, washed with deionized water until neutral, and dried overnight in a constant temperature oven at 120°C to obtain the original SAPO-34 molecular sieve powder, which is then roasted at 550°C for 6 hours to remove tetraethyl groups. After ammonium hydroxide, the S-1 sample was o...

Embodiment 2

[0037] Mix and stir 48.7g pseudo-boehmite, 27.5g silica sol and 60.0g deionized water for 1 hour at room temperature to obtain mixed solution A; add 83.7g orthophosphoric acid and 76.0g triethylamine to mixed solution A in turn and continue Stir for 1 hour to obtain mixed solution B, that is, the SAPO-34 molecular sieve initial gel mixture. The initial gel mixture was put into a high-pressure reactor with a polytetrafluoroethylene liner. After sealing, the reactor was placed in a microwave reactor, heated to 165° C., and crystallized at a constant temperature under autogenous pressure for 0.75 hours. After the reaction kettle is cooled, the solid product is centrifuged, washed with deionized water until neutral, and dried overnight in a thermostat at 120°C to obtain the raw SAPO-34 molecular sieve powder, which is then roasted at 550°C for 6 hours to remove triethylamine After that, the S-2 sample was obtained. The XRD spectrum of the S-2 sample is as follows figure 1 As sho...

Embodiment 3

[0039] Mix 48.7g of pseudo-boehmite, 27.5g of silica sol, and 50.0g of deionized water for 1 hour at room temperature to obtain a mixed solution A; add 83.7g of orthophosphoric acid and 322.5g of tetraethyl hydroxide to the mixed solution A in turn ammonium and continue to stir for 1 hour to obtain mixed solution B, which is the initial gel mixture of SAPO-34 molecular sieves. The initial gel mixture was put into a high-pressure reactor with a polytetrafluoroethylene liner. After sealing, the reactor was placed in a microwave reactor, heated to 165° C., and crystallized at a constant temperature under autogenous pressure for 1.5 hours. After the reaction kettle is cooled, the solid product is centrifuged, washed with deionized water until neutral, and dried overnight in a constant temperature oven at 120°C to obtain the original SAPO-34 molecular sieve powder, which is then roasted at 550°C for 6 hours to remove tetraethyl groups. After ammonium hydroxide, the S-3 sample was o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com