AEI/CHA eutectic molecular sieve containing triethylamine and synthetic method thereof

A technology of molecular sieve and triethylamine, applied in the field of molecular sieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] In the preparation method of the molecular sieve provided by the present invention, the phosphorus source used can be one or a mixture of orthophosphoric acid, phosphate, organic phosphide or phosphorus oxide, wherein the preferred phosphorus source is orthophosphoric acid; It is one or any mixture of aluminum salt, aluminate, activated alumina, alkoxy aluminum, pseudo-boehmite or pseudo-boehmite; the silicon source is silica sol, water glass, activated dioxide One or any mixture of silicon or orthosilicates; the metal heteroatoms (Me) used are from titanium, vanadium, chromium, manganese, iron, cobalt, nickel, copper, zinc, zirconium, molybdenum, magnesium, One or any mixture of calcium, strontium, barium and lanthanum.

[0047] Described synthetic method comprises the following steps:

[0048] a) The silicon source material, the aluminum source material, the phosphorus source material, the metal compound, the template agent and the water are uniformly mixed in propor...

Embodiment 1

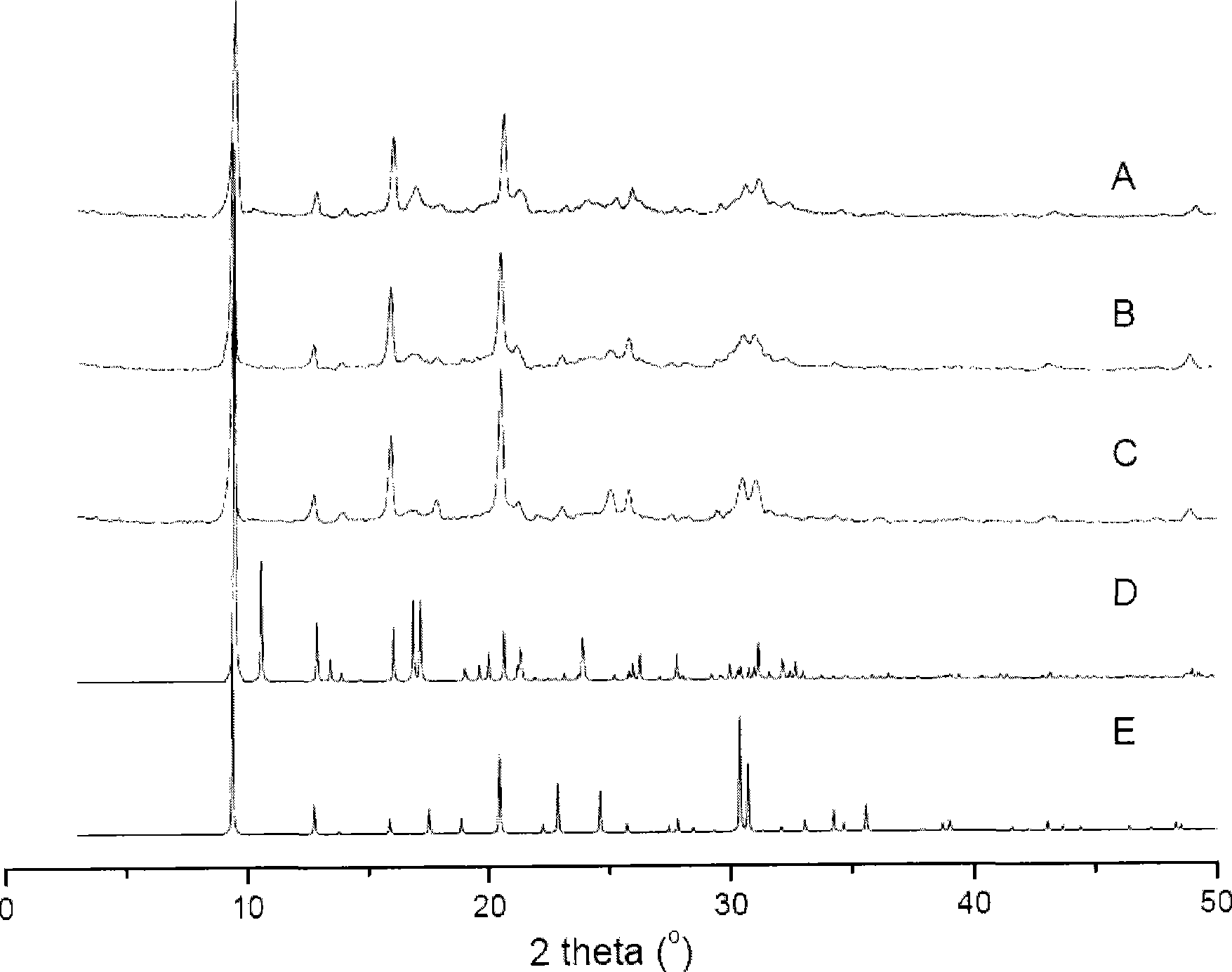

[0059] 11.2 g of pseudo-boehmite (containing Al 2 O 3 72.6wt%, Fushun Petroleum No.3 Catalyst Factory) powder was dissolved in 66ml deionized water, and 18.4g phosphoric acid (containing H 3 PO 4 85wt%, Reagent Factory of Liaoning Pharmaceutical Economic and Trade Corporation) and 5.1g of silica sol (containing SiO 2 28.1wt%, Shanghai Reagent Second Factory). Finally, 24.5 g of triethylamine (analytical grade, Shenyang Xinxi Reagent Factory) was added, and after stirring and mixing evenly, the mixture was transferred into a stainless steel synthesis kettle and sealed. Crystallize at 200 °C and autogenous pressure for 48 hours. The solid product is washed with deionized water until neutral, and dried in air at 100 °C to obtain sample A. The XRD analysis is as follows: figure 1 A shown. The XRD patterns of the obtained samples were compared with those of the simulated standard AEI / CHA eutectic molecular sieves (see "Collection of Simulated XRD Powder Patterns for Zeolite...

Embodiment 2

[0061] 11.2 g of pseudo-boehmite (containing Al 2 O 3 72.6wt%, Fushun Petroleum No.3 Catalyst Factory) powder was dissolved in 60ml deionized water, and 18.4g phosphoric acid (containing H 3 PO 4 85wt%, Reagent Factory of Liaoning Pharmaceutical Economic and Trade Corporation) and 8.5g silica sol (containing SiO 2 28.1wt%, Shanghai Reagent Second Factory). Finally, 22.5g triethylamine (analytical grade, Shenyang Xinxi Reagent Factory) and 10g tetraethylammonium hydroxide (10wt%, Beijing Xingfu Institute of Fine Chemistry) were added, and after stirring and mixing evenly, the mixture was transferred into stainless steel for synthesis Sealed in kettle. Crystallize at 200°C and autogenous pressure for 24 hours. The solid product is washed with deionized water until neutral, and dried in air at 100°C to obtain sample B. The XRD analysis is as follows: figure 1 shown in B. The XRD pattern of the obtained sample was compared with that of the simulated standard AEI / CHA co-cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com