Method for preparing pentafluoroethane

A technology of pentafluoroethane and tetrafluoroethane, which is applied in the field of preparation of pentafluoroethane, can solve the problems of increasing production cost, affecting the life of the catalyst, low conversion rate of PCE per pass, etc., so as to prolong the life of the catalyst and slow down the coking rate. , the effect of improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

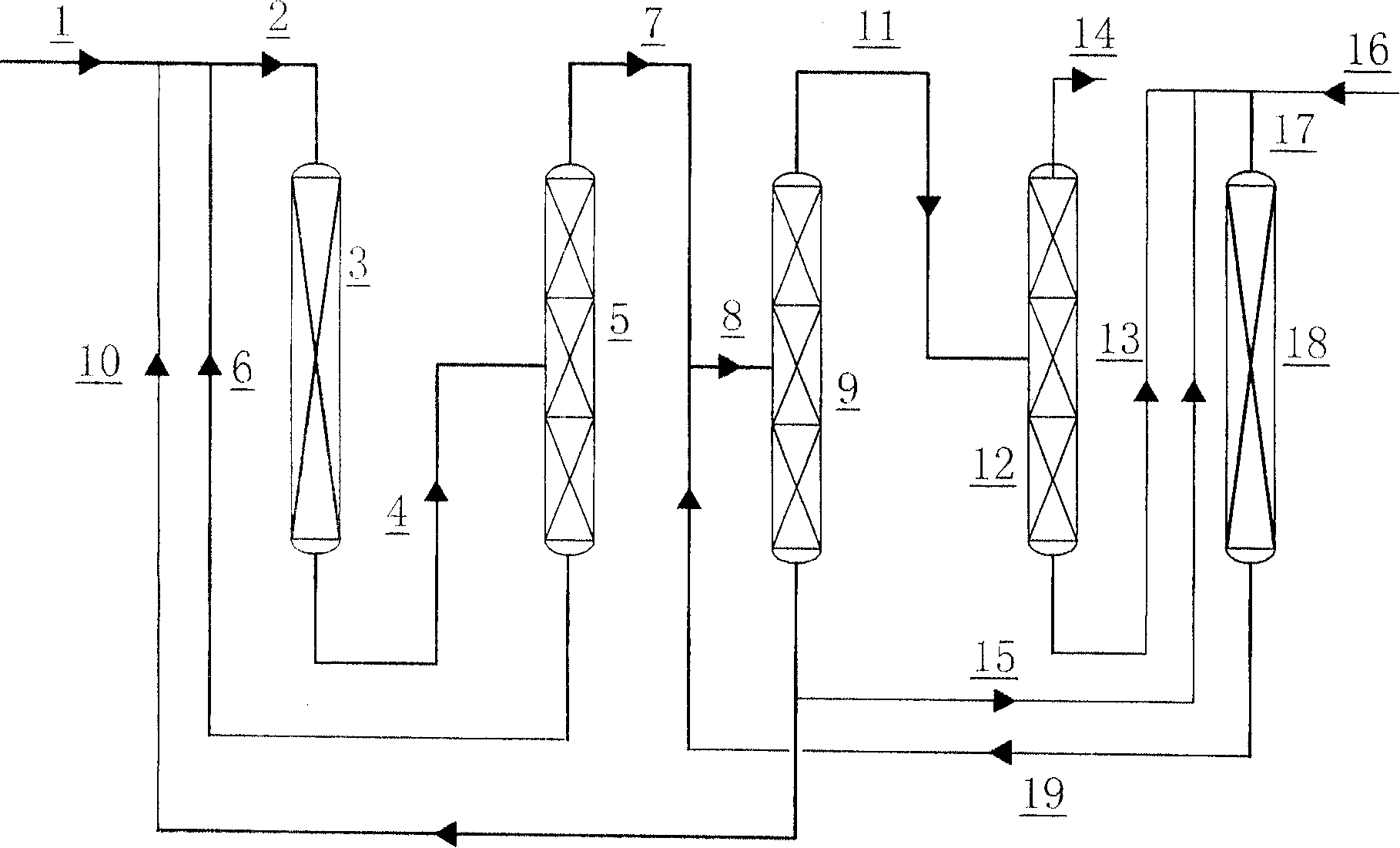

[0038] The present invention will be described in further detail with reference to the accompanying drawings. Fresh PCE or the mixture of PCE and HF enters the first reactor 3 packed with the fluorination catalyst through the pipeline 2 through the pipeline 1 together with the HF stream recycled through the pipeline 10 and the PCE stream recycled through the pipeline 6 to react , the reaction temperature is 280°C to 330°C, the reaction pressure is 0.8MPa to 1.2MPa, the contact time is 10 seconds to 20 seconds, the molar ratio of hydrogen fluoride to tetrachloroethylene is 6 to 10:1, and the reaction product flows through the pipeline 4 into the first distillation tower 5 for separation, the operating pressure of the first distillation tower is 0.8MPa-1.2MPa, the temperature of the tower top is 70°C-100°C, the temperature of the tower bottom is 100°C-150°C, and the PCE containing a small amount of HF in the tower bottom component passes through the line 6 Circulation enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com