Mesoporous titanium-silicon molecular sieve, and preparation method and application thereof

A technology of titanium-silicon molecular sieve and silicon molecular sieve, which is applied in the field of mesoporous nano-titanium-silicon molecular sieve TS-1 and its preparation, can solve the problems of increased catalyst cost, low selectivity, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

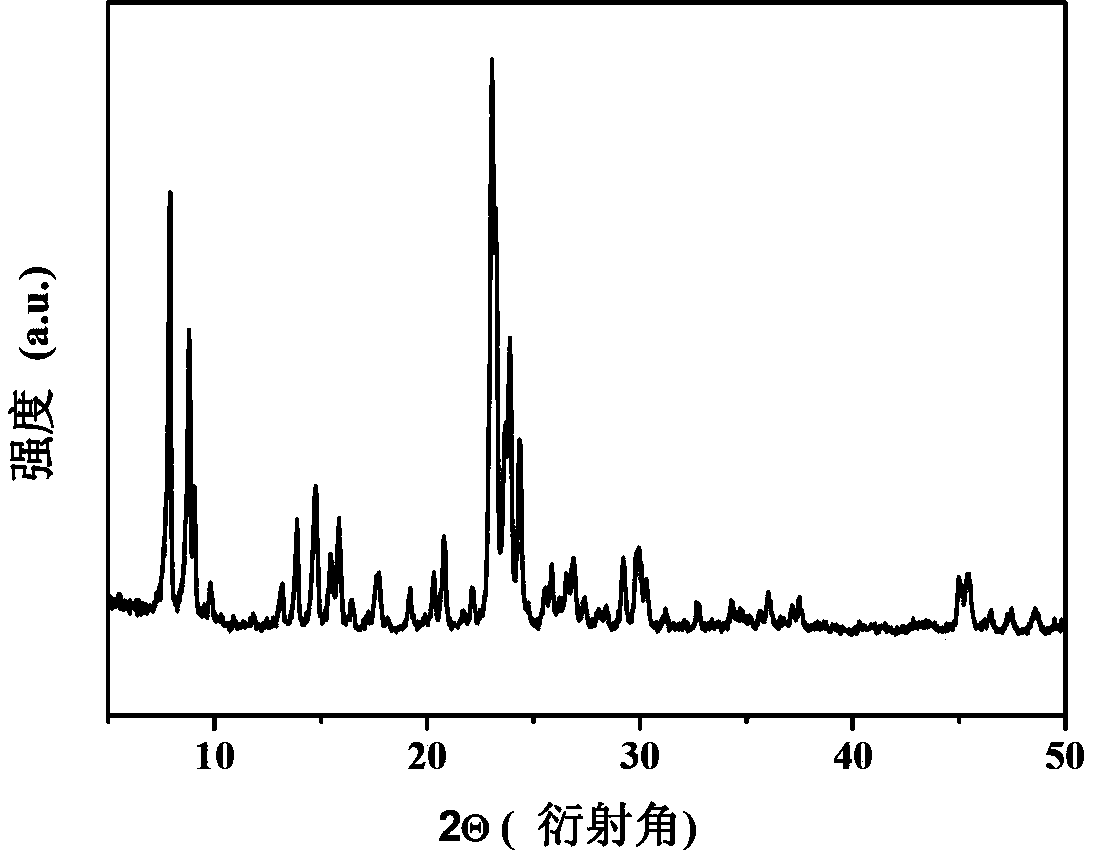

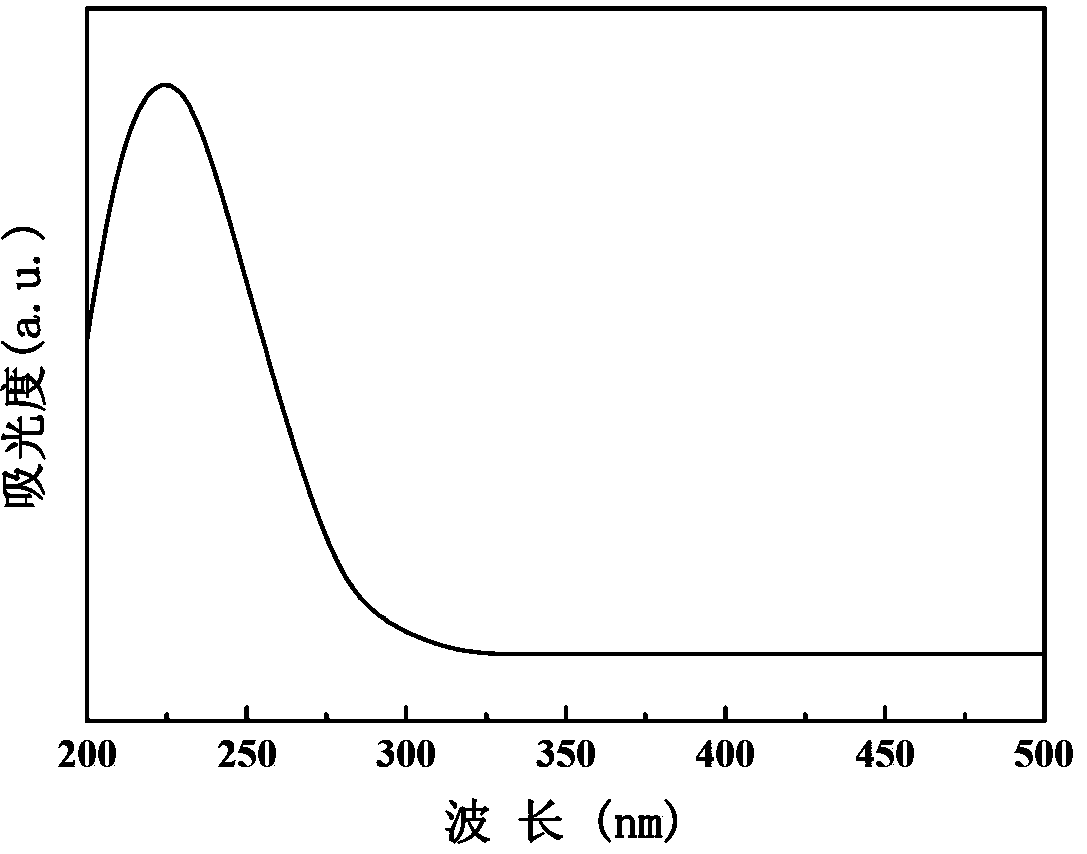

[0065] Preparation of Mesoporous Nano Ti-Si Molecular Sieve TS-1

[0066] Put 12.2g of tetrapropylammonium hydroxide in a beaker, add 30g of water and 11g of ethyl orthosilicate and stir for 30 minutes to obtain solution A. Take 4.5mL of isopropanol and 0.51g of n-butyl titanate, mix evenly, add to A at a rate of 0.2ml / min and stir for 3 hours to obtain solution B. At the same time, 29g of F127 was dissolved in 20g of water to obtain solution C. Add B dropwise to C at a rate of 0.2ml / min, age at 60°C for 6 hours, and remove alcohol at 90°C for 12 hours to dry gel. Put the dry gel in a small beaker, put it into an autoclave containing 10mL of water, crystallize at 160°C for 18 hours, take it out, wash and dry it, and bake it in an air atmosphere at 550°C for 6 hours.

Embodiment 2

[0068] Preparation of Mesoporous Nano Ti-Si Molecular Sieve TS-1

[0069] Put 12.2g of tetrapropylammonium hydroxide in a beaker, add 30g of water and 11g of ethyl orthosilicate and stir for 30 minutes to obtain solution A. Take 4.5mL of isopropanol and mix with 0.034g of n-butyl titanate evenly, add to A at a rate of 0.01ml / min and stir for 5 hours to obtain solution B. At the same time, 2.9g of P123 was dissolved in 20g of water to obtain solution C. Add B dropwise to C at a rate of 0.01ml / min, age at 60°C for 8 hours, and remove alcohol at 90°C for 16 hours to dry gel. Put the dry gel in a small beaker, put it into an autoclave containing 10mL of water, crystallize at 180 degrees for 48 hours, take it out, wash and dry it, and bake it in an air atmosphere at 550 degrees for 6 hours.

Embodiment 3

[0071] Preparation of Mesoporous Nano Ti-Si Molecular Sieve TS-1

[0072] Put 12.2g of tetrapropylammonium hydroxide in a beaker, add 30g of water and 11g of ethyl orthosilicate and stir for 30 minutes to obtain solution A. Take 4.5mL of isopropanol and 0.17g of n-butyl titanate, mix evenly, add to A at a rate of 0.2ml / min and stir for 5 hours to obtain solution B. At the same time, 2.9g of P123 was dissolved in 20g of water to obtain solution C. Add B dropwise to C at a rate of 0.2ml / min, age at 60°C for 8 hours, and remove alcohol at 90°C for 12 hours to dry gel. Put the dry gel in a small beaker, put it into an autoclave containing 10mL of water, crystallize at 170°C for 18 hours, take it out, wash and dry it, and bake it in an air atmosphere at 550°C for 6 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com