Binder-free FAU type molecular sieve particles and preparation method and application thereof

A binder-free, molecular sieve technology, applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as cumbersome process flow and large environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

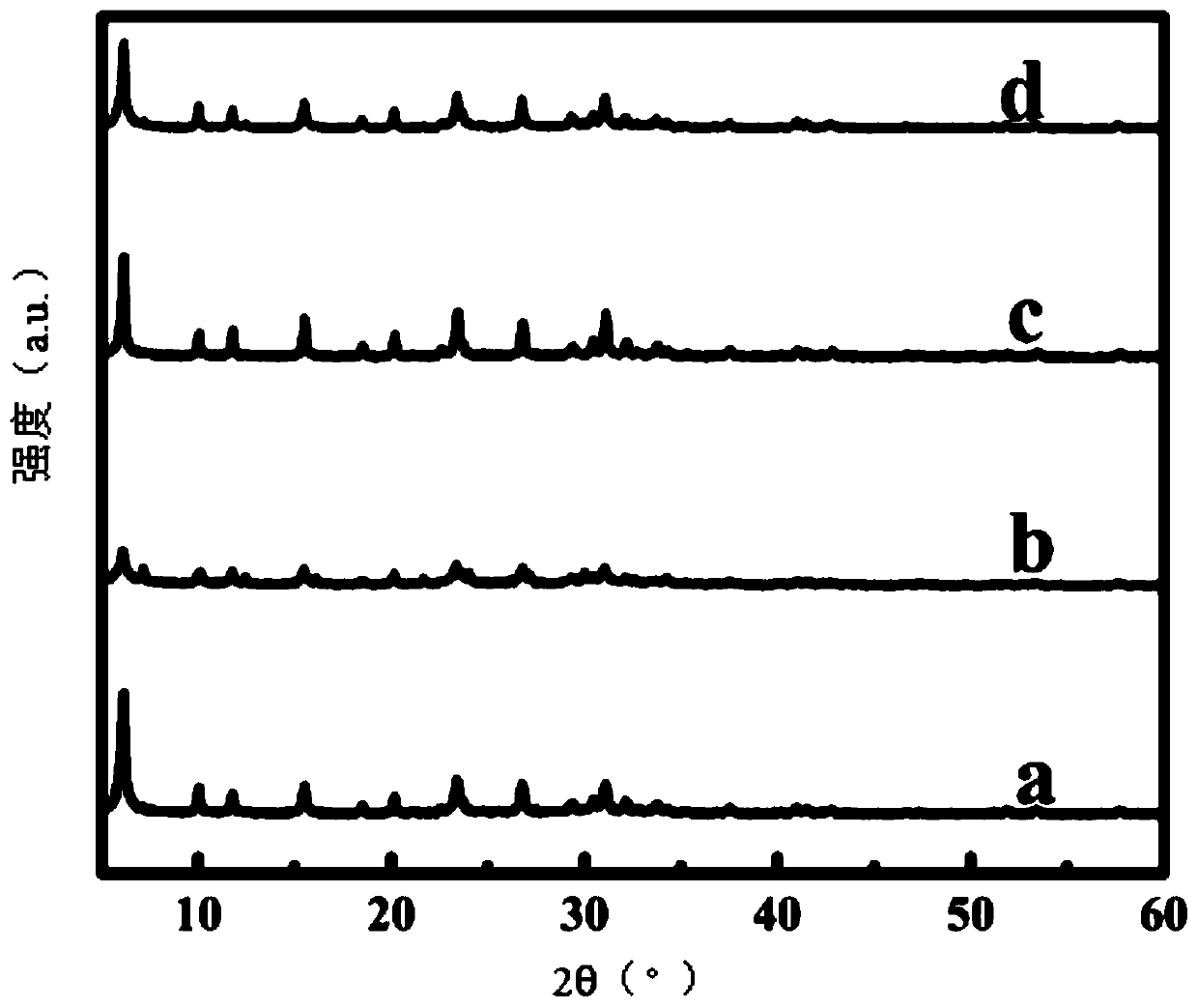

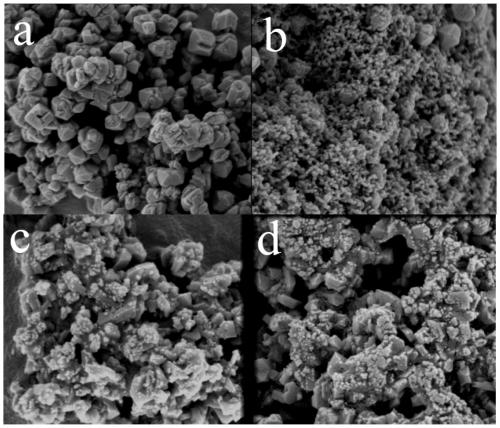

Embodiment 1

[0106] Preparation of oil phase, surfactant phase and water phase three-phase system:

[0107] Dissolve 12.3 parts of sodium metaaluminate and 12.0 parts of sodium hydroxide in 115.0 parts of deionized water, stir to dissolve them and filter with suction to obtain a clear liquid (aqueous phase), and then add 20 parts of CTAB to the top of the obtained clear liquid. Saturated aqueous solution (surfactant phase) and 40 parts of n-heptane (oil phase) to form a three-phase system containing an oil phase, a surfactant phase and an aqueous phase as a solution system for molding the silicone gel precursor.

[0108] Preparation of binder-free FAU molecular sieve particles:

[0109] Weigh 23.5 parts of silica sol (40wt.%, silica nanoparticle size is about 20nm) and 5 parts of ammonium chloride solution (10wt.%), stir quickly and evenly, obtain a silica gel mixture, The mixture is added dropwise to the molding solution system prepared above to obtain a silica gel precursor. After extracting ...

Embodiment 2

[0111] Preparation of oil phase, surfactant phase and water phase three-phase system:

[0112] Dissolve 16.4 parts of sodium metaaluminate and 12.0 parts of sodium hydroxide in 115.0 parts of deionized water, stir to dissolve and filter to obtain a clear liquid (aqueous phase), and then add 20 parts of CTAB to the top of the obtained clear liquid. Saturated aqueous solution (surfactant phase) and 40 parts of n-heptane (oil phase) to form a three-phase system containing an oil phase, a surfactant phase and an aqueous phase as a solution system for molding the silicone gel precursor.

[0113] Preparation of binder-free FAU molecular sieve particles:

[0114] Weigh 23.5 parts of silica sol (40wt.%, silica nanoparticle size is about 20nm) and 5 parts of ammonium chloride solution (10wt.%), stir quickly and evenly, obtain a silica gel mixture, The mixture is added dropwise to the molding solution system prepared above to obtain a silica gel precursor. After extracting and recovering the...

Embodiment 3

[0116] Preparation of oil phase, surfactant phase and water phase three-phase system:

[0117] Dissolve 12.3 parts of sodium metaaluminate and 12.0 parts of sodium hydroxide in 115.0 parts of deionized water, stir to dissolve them and filter with suction to obtain a clear liquid (aqueous phase), and then add 20 parts of CTAB to the top of the obtained clear liquid. Saturated aqueous solution (surfactant phase) and 40 parts of n-heptane (oil phase) to form a three-phase system containing an oil phase, a surfactant phase and an aqueous phase as a solution system for molding the silicone gel precursor.

[0118] Preparation of binder-free FAU molecular sieve particles:

[0119] Weigh 23.5 parts of silica sol (40wt.%, silica nanoparticle size is about 20nm) and 5 parts of ammonium chloride solution (10wt.%), stir quickly and evenly, obtain a silica gel mixture, The mixture is added dropwise to the molding solution system prepared above to obtain a silica gel precursor. After extracting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com