Ethene cracking furnace of one-way radiant section furnace tube and application in chemical field

A technology of ethylene cracking furnace and radiant section, which is applied in the direction of cracking, hydrocarbon cracking to hydrocarbon, non-catalytic thermal cracking, etc., and can solve the problem of increasing pressure of cracking furnace, affecting the uniform distribution of flow rate, and the decline of key indicators such as olefin yield of processing capacity, etc. problems, to achieve the effect of increasing yield, improving overall performance, and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

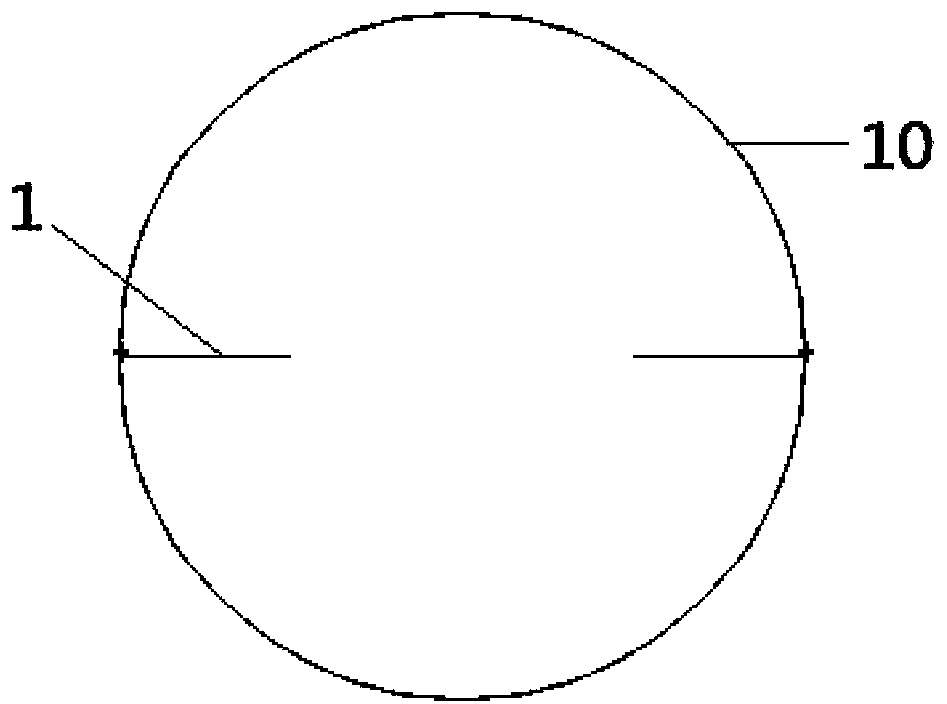

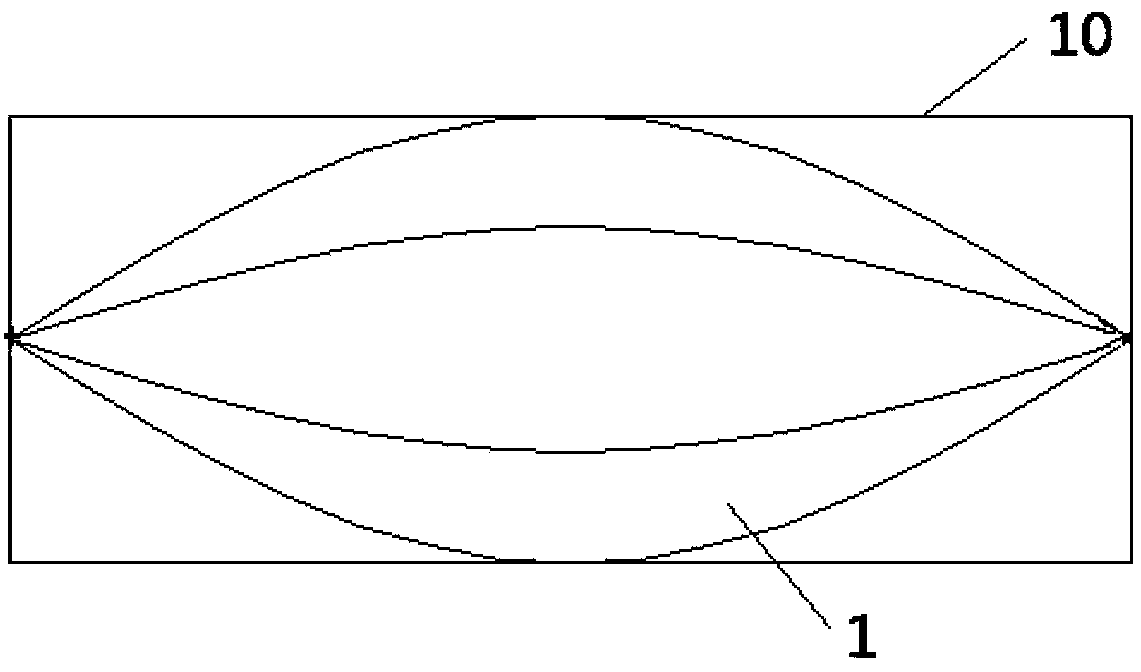

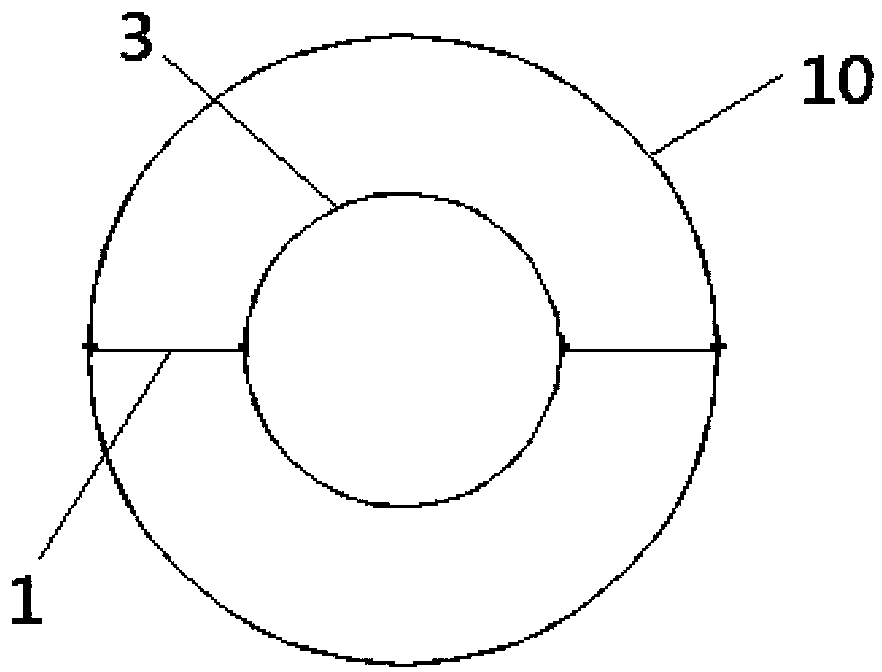

Image

Examples

Embodiment 1

[0102] Take an ethylene cracking furnace with an annual output of 100,000 tons as an example. The ethylene cracking furnace is improved according to a preferred embodiment of the present invention. Under the same process conditions, use the ethylene cracking furnace according to the prior art (the heat exchange tube of the radiant section is not provided with twisted sheets) and the ethylene cracking furnace according to the present invention to carry out comparative experiments, and the process data comparison of the experimental results is as shown in Table 1 As can be seen from Table 1, the pressure drop at the outlet of the radiant section decreases after the styrene heating furnace according to the present invention is used, and the pressure drop at the furnace tube of the radiant section decreases.

[0103]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com