Method for improving stability and activity of catalyst for gas-phase epoxidation of propylene

A catalyst and epoxidation technology, which is applied in the field of preparation of gold-silver alloy catalysts, can solve problems such as low selectivity, difficulty in ensuring stability, and increased catalyst cost, so as to achieve the effect of improving activity and reducing catalyst cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

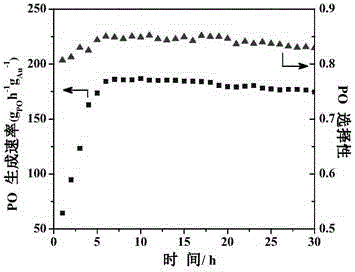

Embodiment 1

[0100] Preparation of gold-silver catalyst

[0101] Take 0.7g of unbaked titanium-silicon molecular sieve and place it in a 250mL beaker, add 35mL of water and 0.67mL of concentration to 3.0×10 -7 mol / mL of AgNO 3 The solution was stirred in a water bath at 80°C for 30 minutes, then adjusted to pH 9 with 0.1mol / L sodium hydroxide, and aged for 2 hours. After centrifugation, it was dried in a vacuum at 25°C for 4 hours. The solid after drying is placed in the 250mL beaker, add 35mL water, 0.063g urea and 0.07mL concentration and be the chloroauric acid solution of 0.003mol / L, under 90 degree of water bath conditions, dark stirring 6 hours, after centrifugation, in 25 Dry under vacuum in the dark for 8 hours.

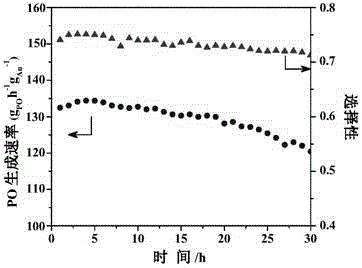

Embodiment 2

[0103] Preparation of gold-silver catalyst

[0104] Take 0.7g of unbaked titanium-silicon molecular sieve and place it in a 250mL beaker, add 35mL of water and 1mL of concentration to 4.63×10 -6 mol / mL of AgNO 3 solution, stirred in a 95-degree water bath for 30 minutes in the dark, then adjusted the pH to 7 with 0.1mol / L sodium hydroxide, aged for 2 hours, and dried in a vacuum at 80 degrees for 4 hours after centrifugation; the dried solid Place in a 250mL beaker, add 35mL water, 0.063g urea and 0.07mL chloroauric acid solution with a concentration of 0.003mol / L, stir in a 90-degree water bath for 6 hours in the dark, centrifuge and dry in a vacuum at 25 degrees in the dark 8 hours.

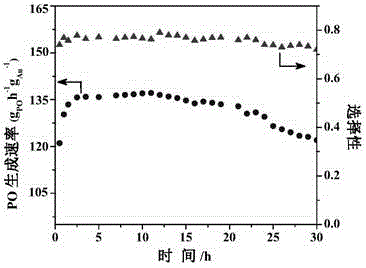

Embodiment 3

[0106] Preparation of gold-silver catalyst

[0107] Take 0.7g of unbaked titanium-silicon molecular sieve and place it in a 250mL beaker, add 35mL of water and 1mL of concentration to 4.63×10 -7 mol / mL of AgNO 3 solution, stirred in a 95-degree water bath for 30 minutes in the dark, then adjusted the pH to 12 with 0.1mol / L sodium hydroxide, aged for 2 hours, centrifuged and dried in a vacuum at 5 degrees in the dark for 4 hours; the dried solid Place in a 250mL beaker, add 35mL water, 0.063g urea and 0.07mL chloroauric acid solution with a concentration of 0.003mol / L, stir for 6 hours in a water bath at 30°C in the dark, centrifuge and dry in a vacuum at 25°C in the dark 8 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com