Silicoaluminophosphate molecular sieve with high silica-alumina ratio and CHA structure, and synthetic method thereof

A technology of silicon-aluminum phosphate and high silicon-aluminum ratio, applied in the direction of molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silico-aluminophosphate, etc. Improved catalytic activity, good technical effect, and reduced coking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

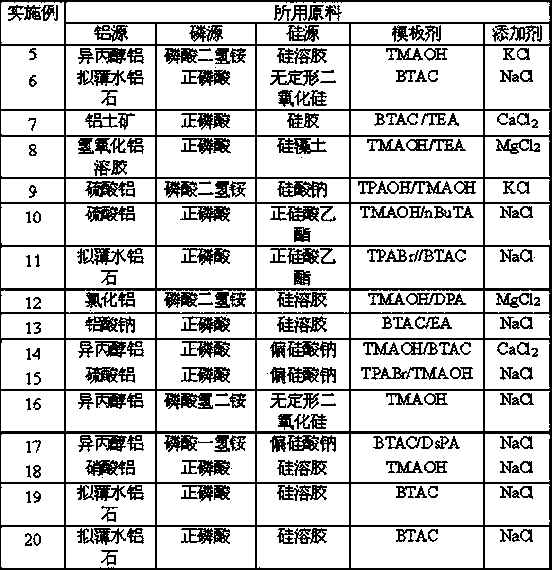

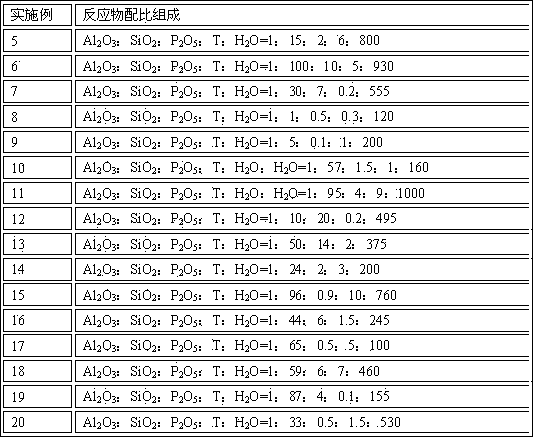

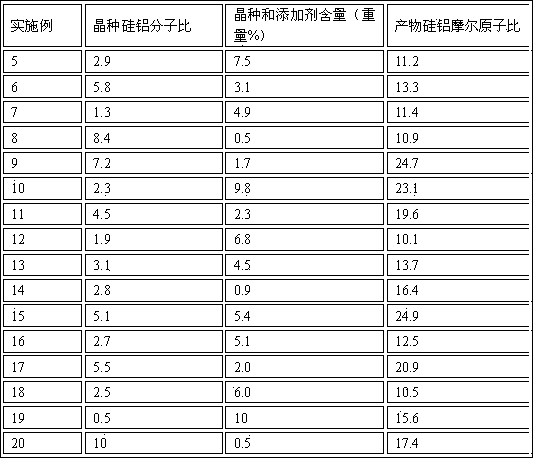

Examples

Embodiment 1

[0029] Weigh 4.3g pseudoboehmite (70wt%, 0.029mmol), 1.7g H 3 PO 4 (85wt%, 0.015 mol) g was dissolved in 151.4mL deionized water, and after stirring evenly, the mixed solution was transferred to an oil bath environment at 40°C, and 2.43g TMAOH (40wt%, 0.06mol) and 126.2g Silica sol (40wt%, 0.84mol), sealed and vigorously stirred until evenly mixed, then put 3.1% USY seed crystals (molar ratio of silicon to aluminum mole ratio is 8.9) and NaCl into the reaction solution and oil Warm up the bath to 60 o C, continue to stir, and after complete mixing, place the crystallized mixture in a polytetrafluoroethylene-lined pressure vessel and crystallize at 140°C for 5 days. After filtering and washing, the product is dried at 130°C, and then heated to 500°C ℃ constant temperature calcination, the existing high silicon aluminum ratio CHA structure silicon aluminum phosphate molecular sieve product, the final silicon aluminum molar atomic ratio of the product measured by the plasma Per...

Embodiment 2

[0032] Weigh 11.5g aluminum isopropoxide (0.056mol) and 3.83g H 3 PO 4 (85wt%, 0.06 mol) g was put into 63.4mL deionized water, and after stirring evenly, the mixed solution was transferred to an oil bath environment at 60°C, and 3.83gBTAC (99wt%, 0.3mol) and 96g silica sol were added under stirring (40wt%, 0.64mol), sealed and vigorously stirred until evenly mixed, then put 2.6% of USY seed crystals (mole ratio of silicon to aluminum molecular is 3.5) and KCl into the reaction solution and raised the temperature of the oil bath to 80 o C Continue to stir, and after it is completely mixed, place the crystallized mixture in a pressure vessel with a polytetrafluoroethylene liner and crystallize at 180°C for 3 days. After the product is filtered and washed, it is dried at 110°C and then heated up Roast at a constant temperature of 550°C to obtain a high-silicon-aluminum ratio CHA-structure silicoaluminophosphate molecular sieve product. The final silicon-aluminum molar atom...

Embodiment 3

[0035] Will Al 2 o 3 The content is 4.3g pseudoboehmite (70wt%, 0.029mol), 5.0g H 3 PO 4 ( 85wt%, 0.043 mol) g, dissolved in 160.8mL deionized water, stirred evenly, transferred the uniformly mixed solution to an oil bath environment at 60°C, and added 13.8gTMAOH (40wt%, 0.033mol), 1.3 gTEA (0.013 mol) and 191.4g silica sol (40wt%, 1.28mol), and after the airtight and vigorous stirring until the mixture is uniform, the USY seed crystal with a silicon-aluminum ratio of 3.6% of the total weight of the dry basis of the reactant (molar ratio of silicon-aluminum molecules 2.4) and NaCl was put into the reaction solution and the oil bath was heated to 80 o C Continue to stir, and after being completely mixed, place the reaction mixture in a pressure vessel with a polytetrafluoroethylene liner and crystallize at 190°C for 1.5 days. The product is filtered and washed, dried at 120°C, and then heated Roast at a constant temperature of 550°C to obtain a high-silicon-aluminum-ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com