Alkali-modified ZSM-5 molecular sieve, preparation method and application thereof

A ZSM-5 and molecular sieve technology, applied in the field of molecular sieves, can solve the problems of reducing catalytic activity and destroying molecular sieves, and achieve the effects of low micropore ratio, increasing solid content, and controlling grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

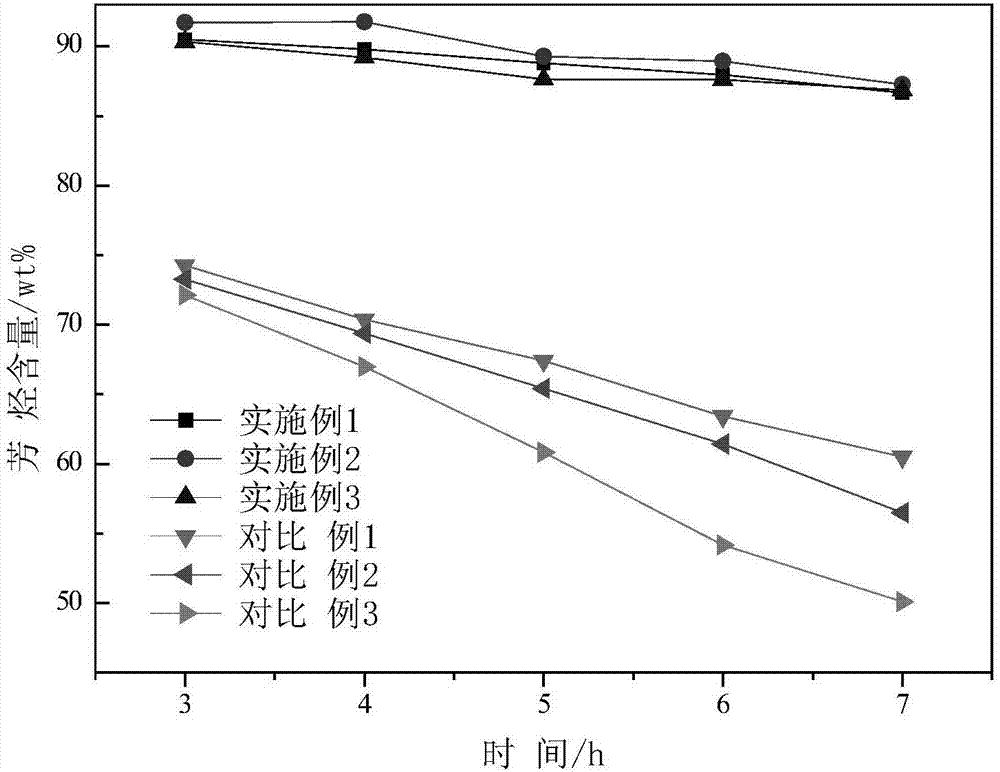

Examples

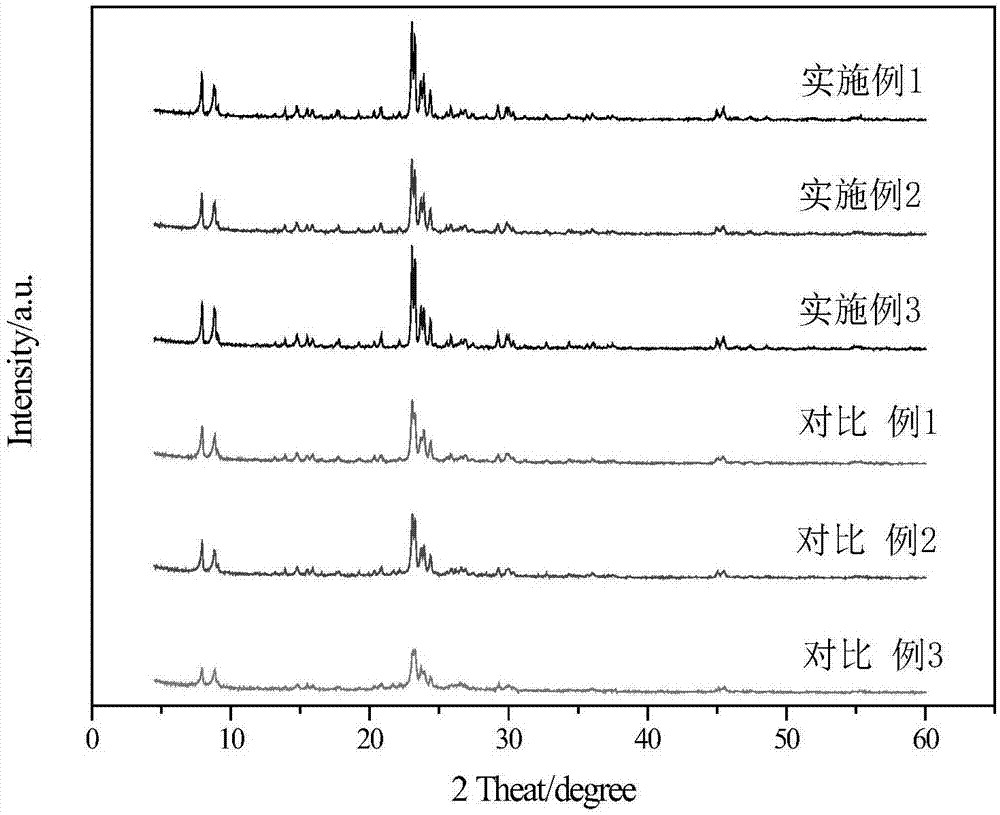

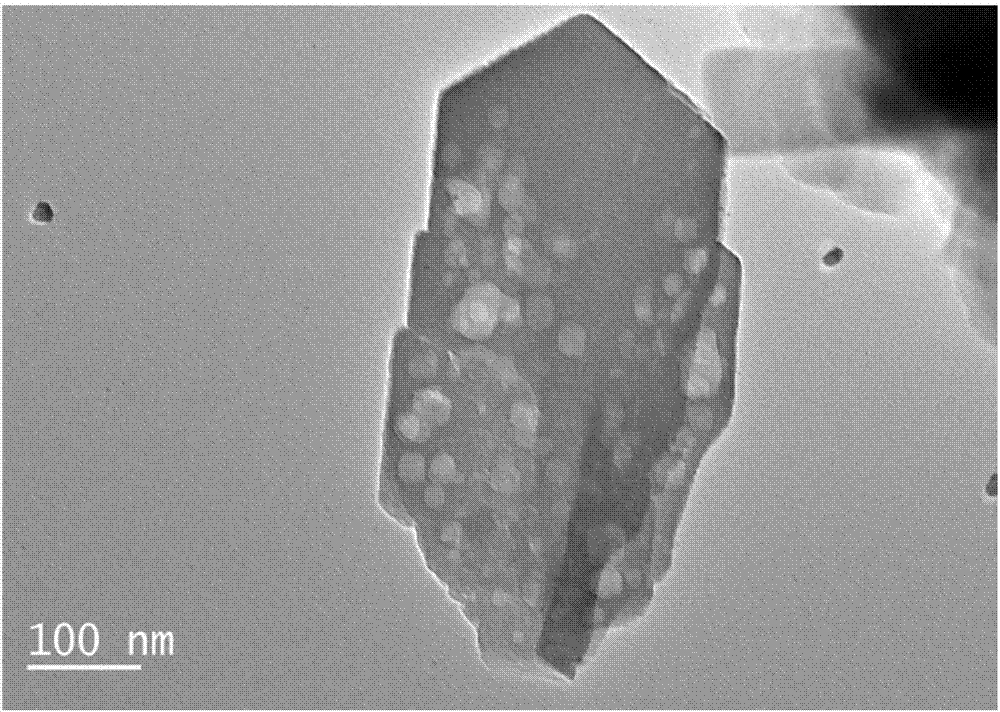

Embodiment 1

[0056] Take 53ml of deionized water and put it in a beaker, add 0.5106g of aluminum isopropoxide and stir for 10min to obtain solution A. Get 22.3ml tetraethyl orthosilicate, add in the solution A with 1.0ml / min speed, add 22g tetrapropyl ammonium hydroxide then, obtain solution B. Solution B was stirred at room temperature for 5h, and alcohol was removed at 80°C for 3h to a transparent solution. Put the transparent solution into an autoclave, crystallize at 170 degrees for 72 hours, take it out, wash and dry it, and roast it in an air atmosphere at 550 degrees for 6 hours to obtain nano ZSM-5 molecular sieves.

[0057] Take 5g of molecular sieves and place them in a beaker, take 50ml of 0.67mol / L tetrapropylammonium hydroxide solution, add it into the beaker at a rate of 5.0ml / min, and stir at room temperature for 1h to obtain solution C. Solution C was put into a crystallization kettle, and stood at 170°C for 48 hours, taken out, washed and dried, and then roasted in an air...

Embodiment 2

[0059] Take 53ml of deionized water and put it in a beaker, add 0.5106g of aluminum isopropoxide and stir for 10min to obtain solution A. Get 22.3ml tetraethyl orthosilicate, add in the solution A with 1.0ml / min speed, add 22g tetrapropyl ammonium hydroxide then, obtain solution B. Solution B was stirred at room temperature for 5h, and alcohol was removed at 80°C for 2h to a transparent solution. Put the transparent solution into an autoclave, crystallize at 170 degrees for 72 hours, take it out, wash and dry it, and roast it in an air atmosphere at 550 degrees for 6 hours to obtain nano ZSM-5 molecular sieves.

[0060] Put 5g of molecular sieves in a beaker, take 50ml of 1.0mol / L tetrapropylammonium hydroxide solution, add it into the beaker at a rate of 5.0ml / min, and stir at room temperature for 1h to obtain solution C. Solution C was put into a crystallization kettle, and stood at 170°C for 48 hours, taken out, washed and dried, and then roasted in an air atmosphere at 55...

Embodiment 3

[0062] Take 53ml of deionized water and put it in a beaker, add 0.5106g of aluminum isopropoxide and stir for 10min to obtain solution A. Get 22.3ml tetraethyl orthosilicate, add in the solution A with 1.0ml / min speed, add 22g tetrapropyl ammonium hydroxide then, obtain solution B. Solution B was stirred at room temperature for 4h, and alcohol was removed at 80°C for 3h to a transparent solution. Put the transparent solution into an autoclave, crystallize at 170 degrees for 72 hours, take it out, wash and dry it, and roast it in an air atmosphere at 550 degrees for 6 hours to obtain nano ZSM-5 molecular sieves.

[0063] Take 5g of molecular sieves and place them in a beaker, take 50ml of 2.0mol / L tetrapropylammonium hydroxide solution, add it into the beaker at a rate of 5.0ml / min, and stir at room temperature for 1h to obtain solution C. Solution C was put into a crystallization kettle, and stood at 170°C for 48 hours, taken out, washed and dried, and then roasted in an air ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com